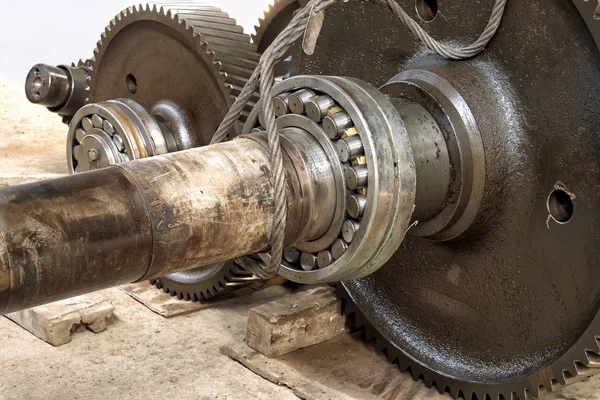

Measuring bearing clearance in machinery is crucial for ensuring optimal performance and longevity of the equipment. Proper bearing clearance helps prevent issues such as overheating, excessive wear, and premature failure. By accurately measuring the clearance, maintenance professionals can make informed decisions about the need for adjustments or replacements, ultimately improving the overall efficiency and reliability of the machinery.

Dial indicators are essential tools for accurately measuring bearing clearance due to their precision and sensitivity. These instruments provide a visual representation of the clearance between the bearing and its housing, allowing technicians to make precise adjustments as needed. By using dial indicators, maintenance professionals can ensure that the bearings are properly installed and functioning within the specified tolerances, minimizing the risk of damage or malfunction.

That major turnout comes as Rodeo Houston saw significantly lower attendance than last year's event nearing the halfway point last week.

Posted by on 2024-03-11

As the Houston Livestock Show and Rodeo wraps up, many are focused on the area's cowboy culture. Black cattle hands living just outside the city played a key part in that history.

Posted by on 2024-03-11

On Monday's show: We talk with NPR's White House Correspondent about the Republican National Convention, then we answer your questions about sleep and gardening--separately, of course.

Posted by on 2024-03-11

Houston ISD is again embroiled in internal strife and public controversy. On Friday, the district released performance ratings to principals. After the Houston Chronicle published details about the ratings, the administration suggested the possibility of legal action against the news outlet and launched an investigation to find the source of the leak.

Posted by on 2024-03-11

There are various types of bearing clearance measurement tools available in the market, including feeler gauges, micrometers, and bore gauges. Feeler gauges are used to measure small clearances between components, while micrometers provide accurate measurements of bearing dimensions. Bore gauges are specifically designed to measure the inner diameter of bearing housings, allowing for precise clearance calculations.

Ultrasonic measurement tools can be used to determine bearing clearance by analyzing the sound waves produced by the bearings. These tools can detect changes in clearance due to factors such as temperature, load, or lubrication, providing valuable insights into the condition of the bearings. By utilizing ultrasonic technology, maintenance professionals can identify potential issues early on and take proactive measures to prevent costly downtime.

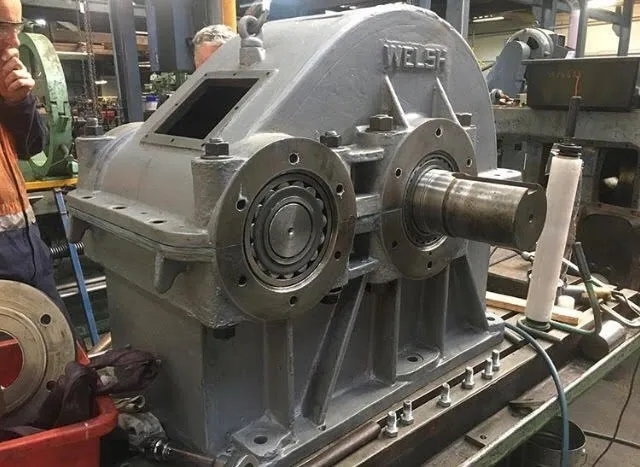

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

The use of laser alignment tools significantly improves the accuracy of bearing clearance measurements by providing precise alignment data. These tools can detect misalignments between bearing components, which can lead to increased clearance and potential damage. By aligning the bearings correctly, maintenance professionals can ensure that the clearance remains within the specified tolerances, optimizing the performance and lifespan of the machinery.

Micrometers play a crucial role in measuring bearing clearance in precision machinery by providing accurate and reliable measurements of bearing dimensions. These instruments are designed to measure small clearances with high precision, allowing maintenance professionals to assess the condition of the bearings with confidence. By using micrometers, technicians can ensure that the bearings are operating within the required tolerances, minimizing the risk of failure or malfunction.

Digital bearing clearance measurement tools are available in the market that provide real-time data for analysis, allowing maintenance professionals to monitor clearance levels continuously. These tools offer advanced features such as data logging, trend analysis, and remote monitoring capabilities, enabling technicians to make informed decisions about maintenance and adjustments. By utilizing digital measurement tools, maintenance teams can improve efficiency, reduce downtime, and extend the lifespan of machinery.

To prevent gearbox vibration, several measures can be taken. First, ensuring proper alignment of the gearbox components, such as shafts and gears, can help reduce vibration. Additionally, using high-quality lubricants and maintaining proper lubrication levels can minimize friction and vibration within the gearbox. Installing vibration dampening mounts or isolators can also help absorb any excess vibration. Regular maintenance and inspections of the gearbox, including checking for worn or damaged parts, can help prevent vibration issues from occurring. Lastly, balancing the rotating components of the gearbox can help reduce vibration and ensure smooth operation. By implementing these measures, gearbox vibration can be effectively prevented.

Gearbox maintenance requirements for automotive applications vary depending on the type of transmission system used in the vehicle. Automatic transmissions may require regular fluid changes, filter replacements, and periodic inspections to ensure proper functioning. Manual transmissions may need clutch adjustments, gear oil changes, and linkage inspections to prevent wear and tear. Additionally, differential maintenance, including fluid changes and gear inspections, is crucial for ensuring optimal performance and longevity of the gearbox. It is important to follow the manufacturer's recommended maintenance schedule and guidelines to avoid costly repairs and breakdowns. Regular maintenance can help extend the lifespan of the gearbox and improve overall vehicle performance.

Gearbox oil should typically be replaced every 30,000 to 50,000 miles, depending on the manufacturer's recommendations and the specific driving conditions. It is important to regularly check the gearbox oil level and quality to ensure optimal performance and longevity of the transmission system. Neglecting to change the gearbox oil at the recommended intervals can lead to increased friction, wear and tear, and potential damage to the gears and bearings. By following the manufacturer's guidelines for gearbox oil replacement, drivers can maintain the efficiency and reliability of their vehicle's transmission system.

Improving gearbox efficiency through upgrades is indeed possible by implementing various enhancements such as optimizing gear ratios, reducing friction losses, upgrading bearings, improving lubrication systems, enhancing thermal management, and utilizing advanced materials for components. These upgrades can result in increased power transmission, reduced energy consumption, improved overall performance, and extended lifespan of the gearbox. By incorporating these enhancements, manufacturers can achieve higher levels of efficiency, reliability, and durability in their gearboxes, ultimately leading to improved productivity and cost savings for end-users. Additionally, advancements in technology and engineering continue to offer new opportunities for further enhancing gearbox efficiency through innovative upgrades and modifications.

Identifying gearbox contamination sources involves conducting a thorough inspection of the surrounding environment, components, and maintenance practices. Potential sources of contamination may include dust, dirt, water ingress, metal particles, lubricant degradation products, and seal failures. Inspecting the gearbox housing, seals, breather vents, filters, and oil samples can help pinpoint the sources of contamination. Additionally, analyzing the operating conditions, maintenance procedures, and equipment design can provide insights into potential contamination sources. Regular monitoring and analysis of gearbox condition can help prevent and address contamination issues before they lead to costly damage and downtime.