Proper gearbox housing alignment is crucial for the overall performance of the equipment. Misalignment can lead to increased wear and tear on the components, reduced efficiency, and even catastrophic failure. It is essential to ensure that the gearbox housing is aligned correctly to prevent these issues and maintain the equipment's optimal functioning.

Operators should be vigilant for common signs of misaligned gearbox housing, such as unusual vibrations, increased noise levels, overheating, and uneven wear on the gears. These indicators can help identify alignment issues early on and prevent further damage to the equipment. Regular inspections and maintenance can help detect and address misalignment promptly.

It's allergy season in Houston, and many are feeling its impact. But allergist Dr. Dat Tran said the pollen count is low compared to 2023.

Posted by on 2024-03-12

A temporary hold on the law was set to expire Wednesday, but the high court extended the pause.

Posted by on 2024-03-12

The Esperanza "Hope" Andrade, named after a former Texas Secretary of State, is the first boat at the Galveston Ferry to be named after a woman and the first in Texas to be named after a Latina, according to TxDOT.

Posted by on 2024-03-12

Other schools in Texas, including University of Houston, will remain test-optional.

Posted by on 2024-03-12

Seven people have died in officer-involved shootings just this month in the Houston area, including in Galveston, Conroe and Montgomery. Each of the men who died was holding a gun at the time that they were shot, and one was brandishing a knife, according to the Houston Police Department.

Posted by on 2024-03-12

To measure gearbox housing alignment accurately, operators typically use tools such as dial indicators, laser alignment systems, and alignment jigs. These tools provide precise measurements of the alignment of the gearbox housing, allowing for adjustments to be made as needed. Proper alignment is essential for ensuring the longevity and efficiency of the equipment.

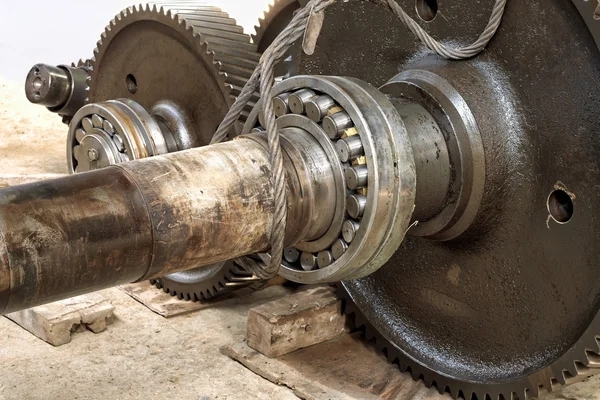

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

When aligning gearbox housing, specific procedures and guidelines should be followed to ensure accuracy and effectiveness. This may include checking and adjusting the alignment of the housing, using shims or other alignment tools, and verifying the alignment with precision instruments. Following these procedures can help prevent misalignment issues and maintain the equipment's performance.

Temperature and environmental conditions can have a significant impact on gearbox housing alignment. Extreme temperatures, humidity, and exposure to harsh elements can cause the housing to expand, contract, or warp, leading to misalignment. It is essential to consider these factors when aligning gearbox housing and take appropriate measures to mitigate their effects.

Neglecting gearbox housing alignment can result in a range of consequences, including increased wear on the gears, reduced efficiency, higher energy consumption, and potential equipment failure. Misalignment can cause unnecessary stress on the components, leading to premature wear and costly repairs. Regular maintenance and alignment checks are essential to prevent these issues.

To maintain gearbox housing alignment over time, operators should follow best practices such as conducting regular inspections, monitoring alignment measurements, and addressing any misalignment issues promptly. Implementing a proactive maintenance schedule and using quality alignment tools can help ensure that the gearbox housing remains properly aligned and the equipment operates at peak performance. By prioritizing alignment maintenance, operators can extend the lifespan of the equipment and avoid costly repairs.

Proper gearbox storage when not in use is essential to maintain its functionality and longevity. The best practices include cleaning the gearbox thoroughly to remove any dirt or debris, applying a protective coating to prevent corrosion, and storing it in a dry and temperature-controlled environment to prevent moisture damage. It is also recommended to rotate the gearbox periodically to prevent any parts from seizing up. Additionally, storing the gearbox in its original packaging or a protective case can help prevent any accidental damage. Following these guidelines will ensure that the gearbox remains in optimal condition for future use.

After assembly, it is crucial to follow best practices for gearbox inspection to ensure optimal performance and longevity. The first step is to visually inspect the gearbox for any signs of damage, such as cracks, leaks, or misalignments. Next, the technician should check the gear teeth for wear, pitting, or chipping, as well as the bearings for any signs of overheating or excessive play. It is also important to verify that all fasteners are properly tightened and that the lubrication levels are adequate. Additionally, conducting a thorough run-in procedure to ensure proper meshing of gears and smooth operation is recommended. Finally, performing vibration analysis and noise level testing can help identify any potential issues before they escalate. By following these best practices, technicians can catch any problems early on and prevent costly repairs or downtime.

When interpreting gearbox temperature readings, it is important to consider various factors such as the operating conditions, lubrication system efficiency, ambient temperature, and the type of gearbox being used. High gearbox temperatures could indicate issues such as inadequate lubrication, overloading, misalignment, or worn-out components. On the other hand, low temperatures may suggest insufficient load or poor heat dissipation. It is crucial to monitor temperature trends over time and compare them to manufacturer recommendations to ensure optimal performance and prevent potential damage. Regular maintenance and inspection can help identify and address any issues related to gearbox temperature readings.

In pharmaceutical applications, there are specific gearbox maintenance requirements that must be adhered to in order to ensure optimal performance and compliance with industry regulations. These requirements may include regular inspections, lubrication checks, and temperature monitoring to prevent contamination and ensure smooth operation. Additionally, proper documentation of maintenance activities and adherence to Good Manufacturing Practices (GMP) are essential in pharmaceutical settings to guarantee the safety and efficacy of products. It is crucial for pharmaceutical companies to work closely with gearbox manufacturers and maintenance professionals to develop a comprehensive maintenance plan tailored to their specific needs and requirements. Failure to properly maintain gearboxes in pharmaceutical applications can result in costly downtime, product recalls, and potential regulatory issues.