In order to optimize the involute gear tooth profile for maximum efficiency in a gearbox, engineers can focus on minimizing friction and wear between the gear teeth. This can be achieved by carefully designing the tooth profile to ensure smooth and gradual contact between mating gears. By optimizing the tooth profile, engineers can reduce energy losses and improve the overall efficiency of the gearbox, leading to better performance and longevity.

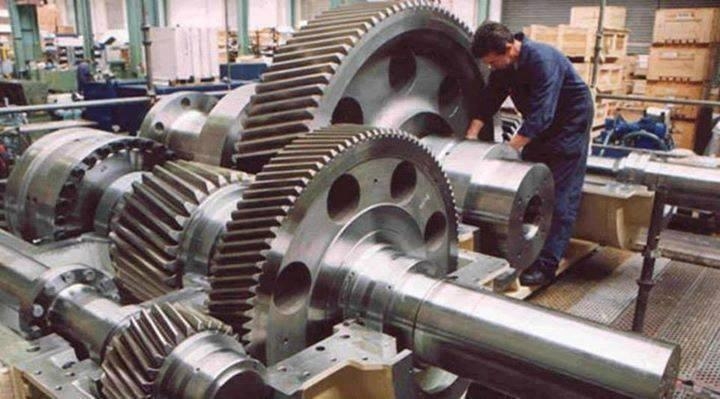

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

The pressure angle plays a crucial role in determining the optimal gear tooth profile for a gearbox. By selecting the appropriate pressure angle, engineers can control the amount of force transmitted between the gear teeth. A higher pressure angle can increase the load-carrying capacity of the gears, while a lower pressure angle can reduce the size of the gears and improve efficiency. By carefully considering the pressure angle, engineers can design gear teeth that are well-suited for the specific requirements of the gearbox.

Roxanna Asgarian discusses her book on the tragedy of the Hart family and their adopted children.

Posted by on 2024-03-13

In Texas and across the country, young people and their families have become increasingly skeptical of the benefits of college. Negative public perception of higher education costs has mostly centered around four-year, private institutions. Experts say community colleges often get lumped into that conversation, even though they usually have lower tuition rates.

Posted by on 2024-03-13

Chief Daniel Rodriguez was taking pre-scheduled vacation time in Phoenix during the Robb Elementary School shooting on May 24, 2022.

Posted by on 2024-03-13

The event will host 20 mile, 40 mile and 60 mile races around the metropolitan, but a map hasn't yet been released. Beginning and ending at Avenida de las Americas at Discovery Green, check-in and registration for the event begins at 6:30 a.m. The routes are secured until 1 p.m., and riders can hop on the sag wagon to continue the ride without support after that, according to the event's webpage.

Posted by on 2024-03-13

Adjusting the addendum modification coefficient can help improve the performance of gear teeth in a gearbox. By modifying the addendum, engineers can optimize the contact pattern between mating gears, leading to reduced stress and wear on the teeth. This adjustment can also help distribute the load more evenly across the gear teeth, improving overall performance and durability of the gearbox. By fine-tuning the addendum modification coefficient, engineers can enhance the efficiency and reliability of the gearbox.

The tip relief of gear teeth plays a significant role in the overall performance and durability of a gearbox. By adding tip relief to the gear teeth, engineers can reduce the risk of interference and improve the meshing characteristics of the gears. This can help prevent damage to the gear teeth and ensure smooth operation of the gearbox. By carefully designing the tip relief, engineers can enhance the performance and longevity of the gearbox, leading to improved reliability and efficiency.

Optimizing the root fillet radius is essential for enhancing the strength and load-carrying capacity of gear teeth in a gearbox. By increasing the root fillet radius, engineers can reduce stress concentrations at the root of the gear teeth, improving their resistance to fatigue and failure. This can help increase the overall durability and performance of the gearbox, ensuring that it can withstand the demands of its application. By carefully selecting the appropriate root fillet radius, engineers can enhance the strength and reliability of the gearbox.

Using asymmetric tooth profiles in gearbox design can offer several benefits, such as reducing noise, improving load distribution, and enhancing efficiency. By optimizing asymmetric tooth profiles for specific applications, engineers can tailor the gear design to meet the unique requirements of the gearbox. This can lead to improved performance, reduced wear, and increased longevity of the gearbox. By carefully designing and optimizing asymmetric tooth profiles, engineers can achieve better results in terms of efficiency and reliability.

Computer-aided design and simulation tools can be invaluable in optimizing gear tooth profiles in a gearbox for maximum performance and longevity. These tools allow engineers to analyze different tooth profiles, simulate their behavior under various operating conditions, and optimize them for specific requirements. By using computer-aided design and simulation tools, engineers can quickly iterate through design options, identify potential issues, and fine-tune the gear tooth profiles to achieve the desired performance. This can lead to more efficient and reliable gearboxes that meet the needs of their intended applications.

When determining the appropriate gearbox lubricant volume, it is important to consider factors such as gear type, operating conditions, and manufacturer recommendations. The volume of lubricant needed will vary depending on the size and design of the gearbox, as well as the speed and load at which it operates. It is crucial to consult the gearbox manual or contact the manufacturer to determine the correct lubricant volume for optimal performance and longevity. Additionally, factors such as temperature, viscosity, and oil type should be taken into account when calculating the appropriate volume of lubricant to ensure proper lubrication and protection of the gearbox components. Regular maintenance and monitoring of the lubricant level are also essential to prevent damage and ensure smooth operation of the gearbox.

When addressing gearbox lubrication blockages, it is important to first identify the root cause of the issue. Common reasons for blockages include contamination, inadequate lubrication, or mechanical failures. To resolve the blockage, one can utilize methods such as flushing the system, replacing the lubricant, cleaning filters, or repairing any damaged components. It is crucial to follow manufacturer guidelines and use appropriate tools and equipment to ensure proper maintenance and prevent future blockages. Regular inspections and maintenance routines can help detect and address blockages before they escalate into more severe problems. By addressing gearbox lubrication blockages promptly and effectively, one can ensure optimal performance and longevity of the equipment.

One way to identify gearbox seal leaks is to look for signs of oil or fluid dripping or pooling underneath the vehicle. Other indicators may include a decrease in fluid levels, visible cracks or damage to the seal itself, and a burning smell coming from the gearbox. Additionally, a visual inspection of the gearbox housing and surrounding components may reveal signs of leakage, such as oil stains or residue. It is important to address gearbox seal leaks promptly to prevent further damage to the transmission system and ensure optimal performance of the vehicle.

Filtration systems play a crucial role in gearbox maintenance by removing contaminants such as dirt, debris, and metal particles from the lubricating oil. These systems help prevent wear and tear on gearbox components, improve overall performance, and extend the lifespan of the gearbox. By capturing and filtering out harmful particles, filtration systems ensure that the lubricating oil remains clean and effective in reducing friction and heat within the gearbox. Regular maintenance of filtration systems is essential to ensure optimal gearbox performance and prevent costly repairs or replacements. Proper filtration also helps maintain the viscosity and integrity of the lubricating oil, ensuring smooth operation and efficient power transmission within the gearbox.

The performance of a gearbox can indeed be affected by humidity levels. High levels of humidity can lead to increased moisture within the gearbox, potentially causing corrosion, rust, and lubrication breakdown. This can result in decreased efficiency, increased friction, and ultimately, a decrease in overall performance. It is important to monitor and control humidity levels in the environment where the gearbox is located to ensure optimal functioning and longevity. Additionally, proper maintenance and regular inspections can help mitigate the negative effects of humidity on gearbox performance.

Recommended maintenance procedures for gearbox housings include regular inspections for signs of wear, corrosion, or leaks. It is important to check the housing for any cracks, dents, or other damage that could compromise its integrity. Additionally, lubrication of the gearbox housing is essential to ensure smooth operation and prevent overheating. Cleaning the housing regularly to remove dirt, debris, and contaminants is also recommended to prevent premature wear and tear. Proper storage of the gearbox housing when not in use can help prolong its lifespan and prevent damage. Overall, following a comprehensive maintenance schedule and addressing any issues promptly can help ensure the longevity and efficiency of gearbox housings.