Gear tooth profile measurement tools play a crucial role in ensuring the accuracy of gear manufacturing processes by providing precise measurements of the gear tooth profiles. These tools help in verifying the dimensions, angles, and shapes of the gear teeth, ensuring that they meet the required specifications. By using gear tooth profile measurement tools, manufacturers can identify any deviations or errors in the gear tooth profiles early in the production process, allowing for adjustments to be made promptly to maintain the quality and performance of the gears.

There are several types of gear tooth profile measurement tools available in the market, including gear measuring machines, gear inspection systems, gear analyzers, and gear profile testers. These tools utilize various technologies such as optical scanning, coordinate measuring, and laser scanning to accurately measure the gear tooth profiles and provide detailed analysis of the gear characteristics.

Roxanna Asgarian discusses her book on the tragedy of the Hart family and their adopted children.

Posted by on 2024-03-13

In Texas and across the country, young people and their families have become increasingly skeptical of the benefits of college. Negative public perception of higher education costs has mostly centered around four-year, private institutions. Experts say community colleges often get lumped into that conversation, even though they usually have lower tuition rates.

Posted by on 2024-03-13

Chief Daniel Rodriguez was taking pre-scheduled vacation time in Phoenix during the Robb Elementary School shooting on May 24, 2022.

Posted by on 2024-03-13

The event will host 20 mile, 40 mile and 60 mile races around the metropolitan, but a map hasn't yet been released. Beginning and ending at Avenida de las Americas at Discovery Green, check-in and registration for the event begins at 6:30 a.m. The routes are secured until 1 p.m., and riders can hop on the sag wagon to continue the ride without support after that, according to the event's webpage.

Posted by on 2024-03-13

The cinema showed films for 64 continuous years, making it one of the longest-running theatres in the country.

Posted by on 2024-03-13

Gear tooth profile measurement tools assist in detecting any deviations or errors in gear tooth profiles by comparing the measured data to the specified design parameters. These tools can identify issues such as tooth profile errors, pitch deviations, runout, and surface finish irregularities. By detecting these deviations early on, manufacturers can take corrective actions to ensure that the gears meet the required quality standards and performance criteria.

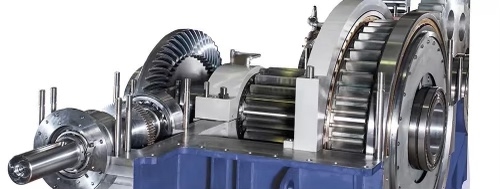

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

When selecting gear tooth profile measurement tools for a specific application, key features to consider include accuracy, repeatability, speed of measurement, ease of use, compatibility with different gear types and sizes, and data analysis capabilities. It is essential to choose a tool that can provide precise measurements consistently and efficiently, allowing for quick decision-making and process optimization.

Gear tooth profile measurement tools contribute to improving the overall quality and performance of gears in various industries by ensuring that the gear tooth profiles meet the required specifications and tolerances. By accurately measuring the gear characteristics, manufacturers can produce gears that operate smoothly, quietly, and efficiently, reducing wear and tear, increasing durability, and enhancing overall performance.

Common challenges faced when using gear tooth profile measurement tools include calibration issues, measurement errors, data interpretation complexities, and software compatibility issues. These challenges can be overcome by regular calibration and maintenance of the measurement tools, training operators on proper usage and data analysis, and ensuring that the software used is up-to-date and compatible with the measurement equipment.

Advancements in technology have a significant impact on the design and functionality of gear tooth profile measurement tools, leading to improved accuracy, speed, and efficiency in measuring gear tooth profiles. Technologies such as 3D scanning, artificial intelligence, and cloud-based data analysis have revolutionized the way gear tooth profiles are measured and analyzed, allowing for more precise and detailed measurements, faster data processing, and enhanced decision-making capabilities in gear manufacturing processes.

To prevent gearbox oil foaming during operation, several measures can be taken. Firstly, ensuring the gearbox is filled with the correct type and amount of oil can help prevent foaming. Additionally, maintaining proper oil levels and changing the oil at recommended intervals can also reduce the likelihood of foaming. Using high-quality oil with anti-foaming additives can further prevent foaming during operation. Proper ventilation and cooling of the gearbox can also help reduce the risk of foaming. Regular inspection of the gearbox for any leaks or damage that could lead to foaming is essential. Overall, following manufacturer guidelines and best practices for gearbox maintenance can help prevent oil foaming during operation.

Proper gearbox storage when not in use is essential to maintain its functionality and longevity. The best practices include cleaning the gearbox thoroughly to remove any dirt or debris, applying a protective coating to prevent corrosion, and storing it in a dry and temperature-controlled environment to prevent moisture damage. It is also recommended to rotate the gearbox periodically to prevent any parts from seizing up. Additionally, storing the gearbox in its original packaging or a protective case can help prevent any accidental damage. Following these guidelines will ensure that the gearbox remains in optimal condition for future use.

After assembly, it is crucial to follow best practices for gearbox inspection to ensure optimal performance and longevity. The first step is to visually inspect the gearbox for any signs of damage, such as cracks, leaks, or misalignments. Next, the technician should check the gear teeth for wear, pitting, or chipping, as well as the bearings for any signs of overheating or excessive play. It is also important to verify that all fasteners are properly tightened and that the lubrication levels are adequate. Additionally, conducting a thorough run-in procedure to ensure proper meshing of gears and smooth operation is recommended. Finally, performing vibration analysis and noise level testing can help identify any potential issues before they escalate. By following these best practices, technicians can catch any problems early on and prevent costly repairs or downtime.

When interpreting gearbox temperature readings, it is important to consider various factors such as the operating conditions, lubrication system efficiency, ambient temperature, and the type of gearbox being used. High gearbox temperatures could indicate issues such as inadequate lubrication, overloading, misalignment, or worn-out components. On the other hand, low temperatures may suggest insufficient load or poor heat dissipation. It is crucial to monitor temperature trends over time and compare them to manufacturer recommendations to ensure optimal performance and prevent potential damage. Regular maintenance and inspection can help identify and address any issues related to gearbox temperature readings.