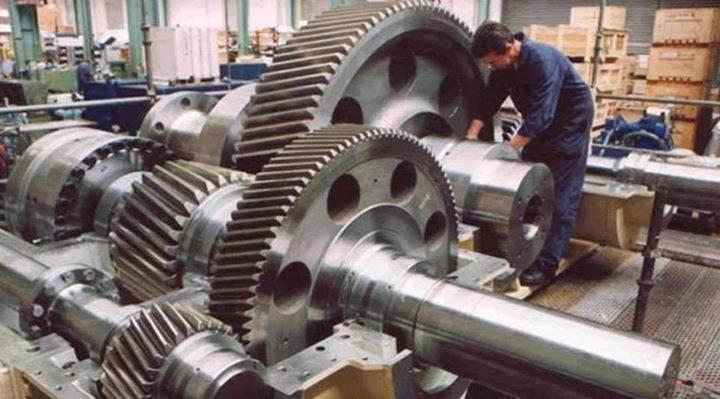

The gear tooth profile in a gearbox plays a crucial role in load distribution among the components. The shape and size of the gear teeth determine how the load is transferred from one gear to another. A well-designed gear tooth profile ensures that the load is evenly distributed across the teeth, minimizing wear and preventing premature failure of the gearbox.

Lubrication is essential for ensuring even load distribution among gearbox components. Proper lubrication reduces friction between moving parts, allowing the gears to rotate smoothly and evenly distribute the load. It also helps dissipate heat generated during operation, preventing overheating and wear. Regular maintenance and monitoring of lubrication levels are necessary to ensure optimal performance and longevity of the gearbox.

Roxanna Asgarian discusses her book on the tragedy of the Hart family and their adopted children.

Posted by on 2024-03-13

In Texas and across the country, young people and their families have become increasingly skeptical of the benefits of college. Negative public perception of higher education costs has mostly centered around four-year, private institutions. Experts say community colleges often get lumped into that conversation, even though they usually have lower tuition rates.

Posted by on 2024-03-13

Chief Daniel Rodriguez was taking pre-scheduled vacation time in Phoenix during the Robb Elementary School shooting on May 24, 2022.

Posted by on 2024-03-13

The event will host 20 mile, 40 mile and 60 mile races around the metropolitan, but a map hasn't yet been released. Beginning and ending at Avenida de las Americas at Discovery Green, check-in and registration for the event begins at 6:30 a.m. The routes are secured until 1 p.m., and riders can hop on the sag wagon to continue the ride without support after that, according to the event's webpage.

Posted by on 2024-03-13

The cinema showed films for 64 continuous years, making it one of the longest-running theatres in the country.

Posted by on 2024-03-13

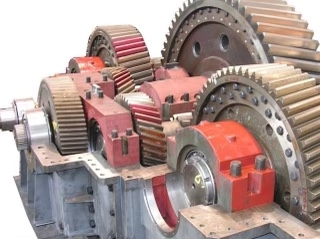

Different types of bearings used in a gearbox can have a significant impact on load distribution. Roller bearings, for example, are designed to handle heavier loads and provide better support for the gears, resulting in more even load distribution. On the other hand, ball bearings are suitable for lighter loads but may not distribute the load as evenly as roller bearings. Choosing the right type of bearing for the specific application is crucial for maintaining proper load distribution.

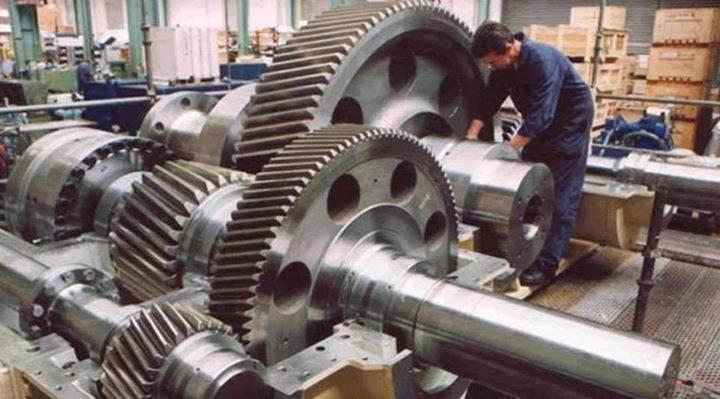

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

Misalignment of gearbox components can lead to uneven load distribution. When gears, shafts, or bearings are not properly aligned, the load may be concentrated on certain parts of the gearbox, causing premature wear and potential failure. Regular alignment checks and adjustments are necessary to ensure that the load is evenly distributed among all components, maximizing the gearbox's efficiency and lifespan.

Temperature fluctuations can have a significant impact on load distribution in a gearbox. Extreme temperatures can affect the viscosity of the lubricant, leading to inadequate lubrication and increased friction between moving parts. This can result in uneven load distribution and accelerated wear of the gearbox components. Proper insulation and cooling mechanisms should be in place to maintain a consistent operating temperature and ensure even load distribution.

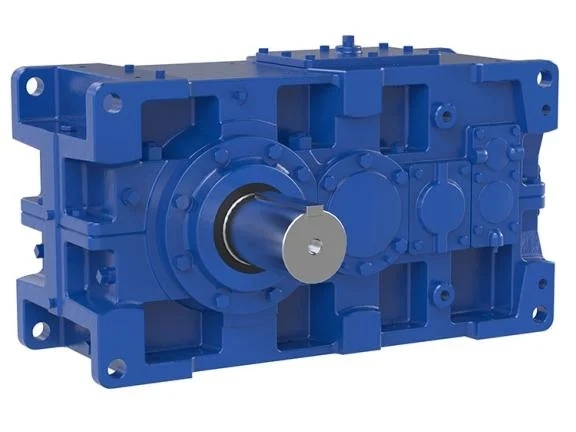

The design of the gearbox housing plays a critical role in load distribution. A well-designed housing provides proper support for the gears, shafts, and bearings, ensuring that the load is evenly distributed across all components. The housing should be rigid and durable to withstand the forces generated during operation and prevent any flexing or deformation that could lead to uneven load distribution. Proper ventilation and cooling features should also be incorporated into the housing design to maintain optimal operating conditions.

Monitoring and adjusting load distribution in a gearbox during operation can be achieved through various methods. Regular inspections and maintenance checks can help identify any issues with load distribution, such as worn gears or misaligned components. Adjustments can be made to the gear mesh, bearing preload, or lubrication levels to ensure that the load is evenly distributed. Advanced monitoring technologies, such as vibration analysis and thermal imaging, can also be used to detect any abnormalities in load distribution and take corrective actions promptly. By implementing a proactive maintenance strategy, gearbox operators can optimize load distribution and prolong the gearbox's lifespan.

Specialized gearbox maintenance procedures for underground mining applications typically involve regular inspections, lubrication checks, and monitoring of vibration levels to ensure optimal performance and prevent breakdowns. These procedures may include the use of specialized tools and equipment, such as vibration analysis devices, to detect potential issues early on. Additionally, maintenance schedules may be more frequent in underground mining settings due to the harsh operating conditions and heavy loads placed on the gearboxes. Proper training for maintenance personnel is also crucial to ensure that all procedures are carried out correctly and efficiently. Overall, the goal of specialized gearbox maintenance in underground mining applications is to maximize equipment uptime and productivity while minimizing the risk of costly downtime.

Balancing can indeed enhance the performance of a gearbox by optimizing the distribution of weight and reducing vibrations that can lead to wear and tear. By carefully adjusting the mass distribution of the components within the gearbox, engineers can improve its efficiency, durability, and overall functionality. This process involves precision machining, dynamic balancing, and the use of specialized tools and techniques to ensure that all parts work together seamlessly. Additionally, balancing can help minimize noise levels, increase power transmission, and extend the lifespan of the gearbox. Overall, balancing plays a crucial role in enhancing gearbox performance and ensuring smooth operation in various applications.

When it comes to gearbox maintenance, there are several specialized tools that can be used to ensure optimal performance and longevity. Some of these tools include gear pullers, bearing pullers, torque wrenches, dial indicators, and gear shimming tools. Gear pullers are used to remove gears from shafts, while bearing pullers are used to remove bearings from gearboxes. Torque wrenches are essential for tightening bolts to the correct specifications, while dial indicators are used to measure gear backlash and runout. Gear shimming tools are used to adjust the spacing between gears for proper meshing. These specialized tools are designed to make gearbox maintenance easier and more efficient, ultimately helping to prevent costly repairs and downtime.

The efficiency of a gearbox can indeed be influenced by the material used for the gearbox housing. The choice of material can impact factors such as heat dissipation, weight, durability, and overall performance. For example, using lightweight materials like aluminum or magnesium can improve the efficiency by reducing the overall weight of the gearbox, leading to less energy loss during operation. Additionally, materials with good thermal conductivity can help dissipate heat more effectively, preventing overheating and improving overall efficiency. On the other hand, using materials with poor durability or high friction coefficients can negatively affect the gearbox's efficiency by increasing wear and energy loss. Therefore, selecting the appropriate gearbox housing material is crucial in optimizing the efficiency and performance of the gearbox.