The involute curve plays a crucial role in determining the gear tooth profile by providing a smooth and gradual transition of contact between gear teeth. This curve ensures that the teeth mesh smoothly and efficiently, reducing wear and noise while maintaining a constant speed ratio. The involute curve also allows for easy manufacturing and inspection of gear teeth, making it a popular choice in gear design.

The pressure angle is a key factor in determining the gear tooth profile as it influences the shape and strength of the gear teeth. A higher pressure angle results in stronger teeth but may also lead to increased sliding friction and wear. On the other hand, a lower pressure angle reduces sliding friction but may compromise the tooth strength. Designers must carefully consider the pressure angle to achieve the desired balance between tooth strength and efficiency in gear systems.

Episode: 2851 The Lake Breeze Fan: Unplanned Obsolescence. Today, invention and obsolescence.

Posted by on 2024-03-12

The Livestock Show and Rodeo will continue through Sunday, March 17.

Posted by on 2024-03-11

The blooming cycle for Texas' state flower is 2-3 weeks ahead of schedule because of earlier-than-usual warm weather, according to Texas A&M horticulturalist Michael Arnold. Bluebonnets already can be seen in places such as the Houston Botanic Garden.

Posted by on 2024-03-11

After Gov. Greg Abbott said there should be consequences for the suspended cases via X, Whitmire suggested the state send money to Houston to help HPD.

Posted by on 2024-03-11

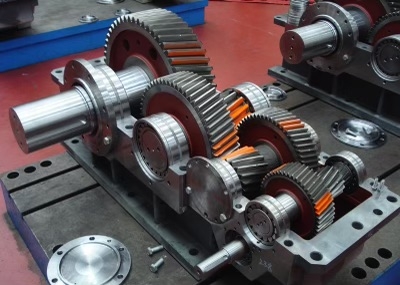

Different types of gear teeth, such as spur gears or helical gears, have a significant impact on the gear tooth profile. Spur gears have straight teeth that are parallel to the gear axis, providing efficient power transmission in applications where noise is not a concern. In contrast, helical gears have angled teeth that offer smoother operation and higher load-carrying capacity but may introduce axial thrust forces. The choice between these gear types depends on the specific requirements of the application.

The addendum and dedendum are critical parameters in gear tooth profile analysis as they determine the tooth's height and depth. The addendum is the distance from the pitch circle to the top of the tooth, while the dedendum is the distance from the pitch circle to the bottom of the tooth. These dimensions affect the strength, contact ratio, and clearance of the gear teeth, influencing the overall performance and durability of the gear system.

The pitch circle diameter plays a crucial role in influencing the gear tooth profile design. It determines the size of the gear teeth and affects the gear ratio, speed, and torque transmission capabilities of the gear system. The pitch circle diameter is used as a reference point for calculating the tooth dimensions and ensuring proper meshing between gears. Designers must carefully consider this parameter to achieve the desired performance characteristics in gear applications.

Tooth thickness and tooth depth are essential factors that impact the gear tooth profile. Tooth thickness refers to the width of the gear tooth at the pitch circle, affecting the load-carrying capacity and contact ratio of the gear system. Tooth depth, on the other hand, determines the strength and meshing characteristics of the gear teeth. Designers must optimize these parameters to ensure proper load distribution and minimize wear in gear applications.

The backlash between gear teeth can significantly affect the overall performance of the gear tooth profile. Backlash refers to the clearance between mating gear teeth, allowing for smooth operation and compensating for manufacturing tolerances. However, excessive backlash can lead to noise, vibration, and reduced efficiency in gear systems. Designers must carefully control the amount of backlash to achieve the desired balance between smooth operation and precise gear meshing.

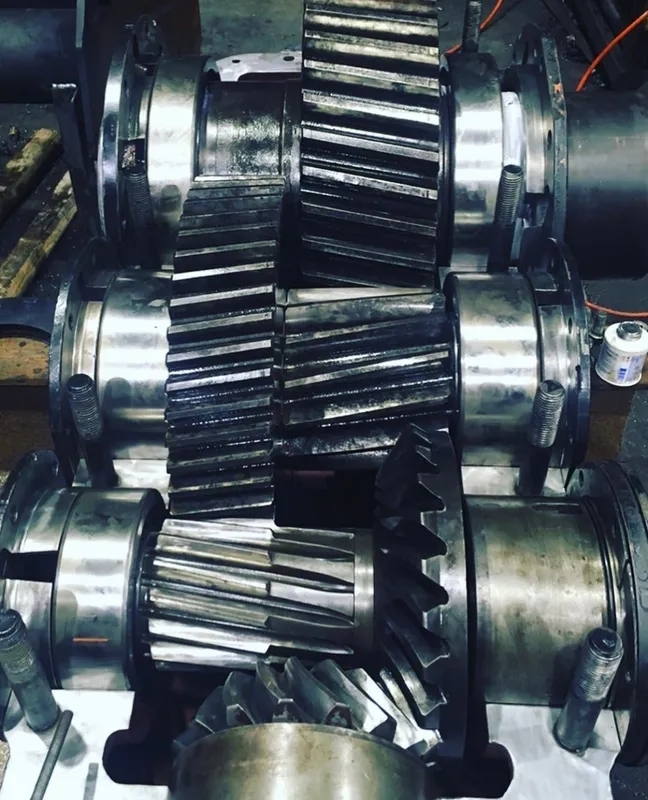

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

Gearbox shaft alignment is typically achieved using precision alignment tools such as dial indicators, laser alignment systems, and alignment jacks. These tools allow technicians to accurately measure and adjust the position of the gearbox shafts to ensure they are perfectly aligned. Additionally, shims, spacers, and adjustable mounts may be used to fine-tune the alignment of the shafts. Proper alignment is crucial for reducing wear and tear on the gearbox components, improving efficiency, and preventing premature failure. Regular maintenance and monitoring of gearbox shaft alignment are essential to ensure optimal performance and longevity of the equipment.

Common signs of gearbox bearing failure include unusual noises such as grinding, whining, or rumbling coming from the transmission, difficulty shifting gears, vibrations felt while driving, leaking transmission fluid, and a burning smell. Other indicators may include a decrease in overall performance, increased fuel consumption, and visible damage to the gearbox components. It is important to address these symptoms promptly to prevent further damage to the transmission system. Regular maintenance and inspections can help identify bearing issues early on and prevent costly repairs down the line.

When troubleshooting gearbox filter blockages, it is important to first identify the root cause of the issue. Common reasons for blockages include debris buildup, oil contamination, or a faulty filter. To address this, one can start by inspecting the filter for any visible signs of blockage or damage. Next, the oil level and quality should be checked to ensure proper lubrication and filtration. Using diagnostic tools such as pressure gauges can help determine if there is a restriction in the filter. If a blockage is confirmed, the filter may need to be cleaned or replaced. Additionally, checking for any leaks or other mechanical issues that may be contributing to the blockage is recommended. Regular maintenance and monitoring of the gearbox filter can help prevent future blockages and ensure optimal performance of the system.

When addressing gearbox gear tooth wear, it is important to first identify the root cause of the issue. Common factors that contribute to gear tooth wear include improper lubrication, misalignment, overloading, and poor gear meshing. To mitigate wear, one can implement regular maintenance schedules, use high-quality lubricants, ensure proper alignment of gears, and monitor load distribution. Additionally, utilizing advanced technologies such as vibration analysis and thermography can help detect early signs of wear and prevent further damage. By addressing these factors proactively, one can extend the lifespan of gearbox gears and optimize their performance.