Gearbox seal installation tools differ from regular seal installation tools in their design and functionality. Gearbox seal installation tools are specifically designed to fit the unique shape and size of gearbox seals, ensuring a proper and secure installation. These tools often have specialized features such as adjustable arms or handles to accommodate different gearbox seal sizes and shapes, as well as a durable construction to withstand the pressure and force required for installation.

When looking for gearbox seal installation tools, key features to consider include the tool's compatibility with a wide range of gearbox seal sizes, its durability and strength to withstand the installation process, and any additional features such as adjustable arms or handles for versatility. It is also important to look for tools that are easy to use and provide a secure grip to prevent slippage during installation.

It's allergy season in Houston, and many are feeling its impact. But allergist Dr. Dat Tran said the pollen count is low compared to 2023.

Posted by on 2024-03-12

A temporary hold on the law was set to expire Wednesday, but the high court extended the pause.

Posted by on 2024-03-12

The Esperanza "Hope" Andrade, named after a former Texas Secretary of State, is the first boat at the Galveston Ferry to be named after a woman and the first in Texas to be named after a Latina, according to TxDOT.

Posted by on 2024-03-12

Other schools in Texas, including University of Houston, will remain test-optional.

Posted by on 2024-03-12

While gearbox seal installation tools are specifically designed for gearbox seals, they can often be used for other types of seals as well. However, it is important to ensure that the tool is compatible with the size and shape of the seal being installed to prevent damage or improper installation. Some gearbox seal installation tools may have adjustable features that allow them to be used for a variety of seal types.

There are specific sizes of gearbox seal installation tools available for different gearbox models. Manufacturers often produce a range of tools to accommodate various gearbox seal sizes and shapes, ensuring a proper fit and installation for each specific gearbox model. It is important to select the correct size of tool for the gearbox seal being installed to prevent damage and ensure a secure seal.

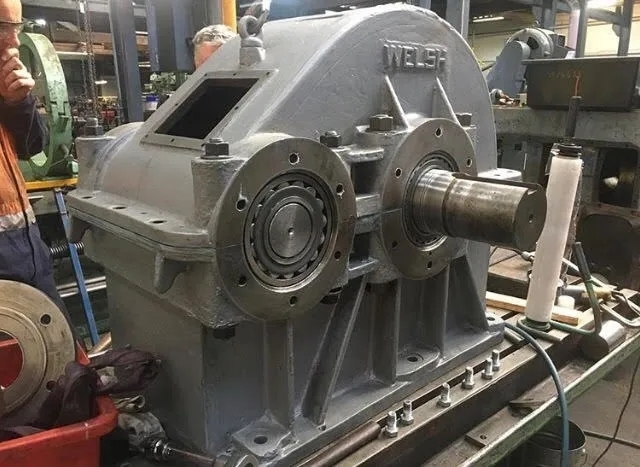

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

The recommended method for using gearbox seal installation tools is to first ensure that the tool is compatible with the size and shape of the gearbox seal. Next, carefully position the tool over the seal and apply even pressure to press the seal into place. It is important to follow the manufacturer's instructions for proper installation to ensure a secure and leak-free seal.

When using gearbox seal installation tools, it is important to observe safety precautions to prevent injury or damage. This includes wearing appropriate protective gear such as gloves and safety glasses, as well as ensuring that the tool is securely positioned over the seal before applying pressure. It is also important to use caution when working with gearbox components to prevent accidents or damage.

Gearbox seal installation tools contribute to the overall efficiency of gearbox maintenance by providing a reliable and secure method for installing seals. These tools help to ensure that seals are properly installed, reducing the risk of leaks and damage to gearbox components. By using gearbox seal installation tools, maintenance technicians can work more efficiently and effectively, saving time and resources in the long run.

To prevent gearbox rusting, it is important to regularly inspect and maintain the gearbox components. This includes checking for any signs of corrosion, such as rust spots or discoloration, and addressing them promptly. Applying a protective coating or lubricant to the gearbox can help prevent moisture from causing rust to form. Keeping the gearbox clean and dry, storing it in a climate-controlled environment, and using rust-resistant materials in the construction of the gearbox can also help prevent rusting. Additionally, using rust inhibitors or desiccants can further protect the gearbox from corrosion. Regularly monitoring the gearbox for any signs of rust and taking proactive measures to prevent it can help extend the lifespan of the gearbox and ensure optimal performance.

The efficiency of a gearbox can indeed be affected by the gearbox gear ratio. The gear ratio in a gearbox refers to the relationship between the number of teeth on the input gear to the number of teeth on the output gear. A higher gear ratio means that the output gear will rotate more times for every rotation of the input gear. This can impact the efficiency of the gearbox as higher gear ratios can lead to increased friction and energy losses due to the increased number of gear engagements. Conversely, lower gear ratios can improve efficiency by reducing the number of gear engagements and minimizing energy losses. Therefore, selecting the appropriate gear ratio is crucial in optimizing the efficiency of a gearbox.

To prevent gearbox oil oxidation, several measures can be taken. One effective method is to use high-quality synthetic oils that contain antioxidants and anti-oxidation additives. Regularly changing the gearbox oil at recommended intervals can also help prevent oxidation. Keeping the gearbox properly sealed and protected from moisture and contaminants can further reduce the risk of oxidation. Additionally, maintaining proper operating temperatures and avoiding excessive heat can help prolong the life of the gearbox oil and prevent oxidation. Monitoring the oil condition regularly through oil analysis can also help detect early signs of oxidation and take corrective actions. Overall, a combination of using high-quality oils, regular maintenance, proper sealing, and monitoring can help prevent gearbox oil oxidation.

Gearbox breather vents play a crucial role in maintenance by allowing for the release of excess pressure and preventing the buildup of moisture and contaminants within the gearbox. These vents help to regulate the internal temperature of the gearbox, ensuring optimal performance and longevity of the components. By allowing for the escape of gases and preventing the ingress of debris, breather vents help to maintain the proper lubrication and functionality of the gearbox. Regular inspection and maintenance of these vents are essential to prevent issues such as overheating, corrosion, and premature wear of gearbox components. Proper care of gearbox breather vents can extend the lifespan of the gearbox and reduce the likelihood of costly repairs.

The key components of a gearbox lubrication system include a reservoir or oil pan to store the lubricant, a pump to circulate the oil throughout the gearbox, a filter to remove any contaminants from the oil, and a series of channels or passages to distribute the oil to the various components of the gearbox. Additionally, there may be sensors to monitor the oil level and temperature, as well as valves to control the flow of oil. Proper lubrication is essential for reducing friction, dissipating heat, and preventing wear and tear on the gearbox components, ultimately extending the lifespan of the system. Regular maintenance and monitoring of the lubrication system are crucial to ensure optimal performance and efficiency.