In gearbox applications, there are several types of bearing caging methods commonly used, including ball bearing caging, roller bearing caging, and needle bearing caging. Each method has its own unique design and characteristics that make it suitable for different types of gearboxes and operating conditions.

The selection of bearing caging method can have a significant impact on the performance and durability of gearboxes. The type of caging used can affect factors such as load capacity, speed capability, noise levels, and overall efficiency. It is important to carefully consider the specific requirements of the gearbox application when choosing a bearing caging method to ensure optimal performance and longevity.

Other schools in Texas, including University of Houston, will remain test-optional.

Posted by on 2024-03-12

Seven people have died in officer-involved shootings just this month in the Houston area, including in Galveston, Conroe and Montgomery. Each of the men who died was holding a gun at the time that they were shot, and one was brandishing a knife, according to the Houston Police Department.

Posted by on 2024-03-12

Houston Matters goes behind the scenes of the University of Houston-Downtown's new digital concert series.

Posted by on 2024-03-12

Don McLaughlin, who called on the investigation, said acting police chief Mariano Pargas failed as a leader on the day of the mass shooting.

Posted by on 2024-03-12

Rivera last week was charged with capital murder and police escalated their searching efforts for the suspect.

Posted by on 2024-03-12

When it comes to using a ball bearing caging method in gearboxes, there are both advantages and disadvantages to consider. Ball bearings are known for their high precision and smooth operation, making them ideal for applications requiring high speeds and low friction. However, they may not be as suitable for heavy-duty applications that require higher load capacities compared to roller bearings.

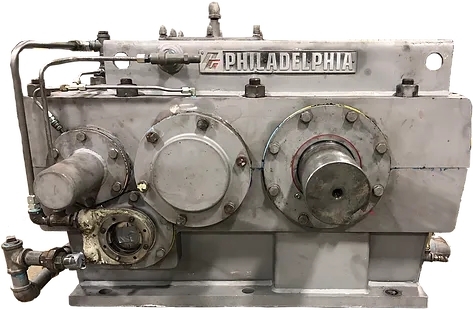

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

The material of the bearing cage plays a crucial role in the overall functionality of gearboxes. The cage material must be able to withstand the operating conditions of the gearbox, including temperature, speed, and load. Common materials used for bearing cages include steel, brass, and plastic, each offering different levels of durability, heat resistance, and lubrication compatibility.

Roller bearing caging methods differ from ball bearing caging methods in gearbox applications in terms of design and performance characteristics. Roller bearings typically have higher load capacities and are better suited for applications with heavier loads and higher speeds. They are also more resistant to shock and vibration compared to ball bearings, making them ideal for rugged gearbox applications.

When choosing a bearing caging method for high-speed gearboxes, there are specific design considerations that need to be taken into account. High-speed applications require bearings that can handle increased centrifugal forces and thermal effects, so selecting a caging method with low friction and high precision is essential. Additionally, proper lubrication and cooling systems must be in place to ensure the bearings operate efficiently at high speeds.

The lubrication system in gearboxes interacts with the bearing caging method to ensure optimal performance and longevity. Proper lubrication is essential for reducing friction, preventing wear, and dissipating heat generated during operation. The type of lubricant used, as well as the frequency of lubrication, must be carefully chosen to match the specific requirements of the bearing caging method and gearbox application. Regular maintenance and monitoring of the lubrication system are crucial for maximizing the lifespan of the gearbox components.

When it comes to gearbox maintenance, there are several specialized tools that can be used to ensure optimal performance and longevity. Some of these tools include gear pullers, bearing pullers, torque wrenches, dial indicators, and gear shimming tools. Gear pullers are used to remove gears from shafts, while bearing pullers are used to remove bearings from gearboxes. Torque wrenches are essential for tightening bolts to the correct specifications, while dial indicators are used to measure gear backlash and runout. Gear shimming tools are used to adjust the spacing between gears for proper meshing. These specialized tools are designed to make gearbox maintenance easier and more efficient, ultimately helping to prevent costly repairs and downtime.

The efficiency of a gearbox can indeed be influenced by the material used for the gearbox housing. The choice of material can impact factors such as heat dissipation, weight, durability, and overall performance. For example, using lightweight materials like aluminum or magnesium can improve the efficiency by reducing the overall weight of the gearbox, leading to less energy loss during operation. Additionally, materials with good thermal conductivity can help dissipate heat more effectively, preventing overheating and improving overall efficiency. On the other hand, using materials with poor durability or high friction coefficients can negatively affect the gearbox's efficiency by increasing wear and energy loss. Therefore, selecting the appropriate gearbox housing material is crucial in optimizing the efficiency and performance of the gearbox.

Gearbox seals can indeed degrade over time due to various factors such as exposure to heat, friction, and contaminants. The material composition of the seals, including rubber or silicone, can break down over time, leading to cracks, leaks, and overall deterioration. Additionally, environmental conditions, such as temperature fluctuations and moisture, can also contribute to the degradation of gearbox seals. Regular maintenance and inspection of seals are crucial to ensure optimal performance and prevent potential issues with the gearbox system. It is important to replace worn-out seals promptly to avoid more significant damage to the gearbox components.

To prevent gearbox vibration, several measures can be taken. First, ensuring proper alignment of the gearbox components, such as shafts and gears, can help reduce vibration. Additionally, using high-quality lubricants and maintaining proper lubrication levels can minimize friction and vibration within the gearbox. Installing vibration dampening mounts or isolators can also help absorb any excess vibration. Regular maintenance and inspections of the gearbox, including checking for worn or damaged parts, can help prevent vibration issues from occurring. Lastly, balancing the rotating components of the gearbox can help reduce vibration and ensure smooth operation. By implementing these measures, gearbox vibration can be effectively prevented.

Gearbox maintenance requirements for automotive applications vary depending on the type of transmission system used in the vehicle. Automatic transmissions may require regular fluid changes, filter replacements, and periodic inspections to ensure proper functioning. Manual transmissions may need clutch adjustments, gear oil changes, and linkage inspections to prevent wear and tear. Additionally, differential maintenance, including fluid changes and gear inspections, is crucial for ensuring optimal performance and longevity of the gearbox. It is important to follow the manufacturer's recommended maintenance schedule and guidelines to avoid costly repairs and breakdowns. Regular maintenance can help extend the lifespan of the gearbox and improve overall vehicle performance.