When considering a lubrication system overhaul, there are several common signs that indicate the need for such maintenance. These signs may include increased noise coming from the system, decreased performance or efficiency, visible leaks or drips of oil, and a noticeable decrease in lubricant levels. Additionally, if there is a presence of contaminants in the oil, such as metal shavings or debris, it may be a clear indication that an overhaul is necessary to prevent further damage to the system.

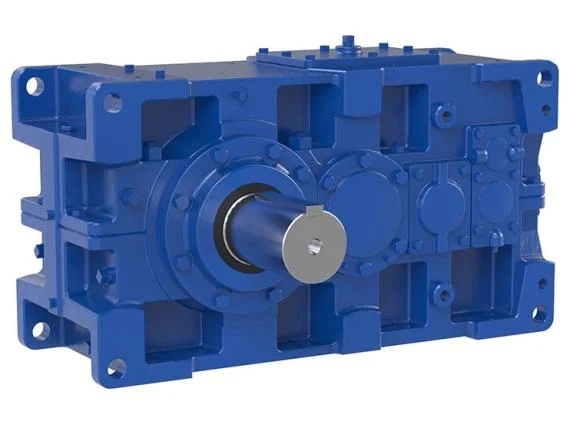

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

During a lubrication system overhaul, it is recommended to replace the oil filter as part of the maintenance process. The frequency at which the oil filter should be replaced can vary depending on the specific system and usage conditions. However, a general guideline is to replace the oil filter every time the lubrication system undergoes an overhaul to ensure optimal performance and longevity of the system.

It's allergy season in Houston, and many are feeling its impact. But allergist Dr. Dat Tran said the pollen count is low compared to 2023.

Posted by on 2024-03-12

A temporary hold on the law was set to expire Wednesday, but the high court extended the pause.

Posted by on 2024-03-12

The Esperanza "Hope" Andrade, named after a former Texas Secretary of State, is the first boat at the Galveston Ferry to be named after a woman and the first in Texas to be named after a Latina, according to TxDOT.

Posted by on 2024-03-12

Other schools in Texas, including University of Houston, will remain test-optional.

Posted by on 2024-03-12

Seven people have died in officer-involved shootings just this month in the Houston area, including in Galveston, Conroe and Montgomery. Each of the men who died was holding a gun at the time that they were shot, and one was brandishing a knife, according to the Houston Police Department.

Posted by on 2024-03-12

When conducting a lubrication system overhaul, it is crucial to inspect and potentially replace key components to maintain the system's functionality. Some of the components that should be thoroughly inspected and replaced if necessary include the oil pump, oil lines, fittings, seals, gaskets, and any other parts that show signs of wear or damage. By addressing these components during the overhaul, the system can operate efficiently and effectively.

In the process of a lubrication system overhaul, it is typically necessary to flush the entire system to remove any accumulated contaminants, sludge, or debris that may have built up over time. Flushing the entire system ensures that all components are thoroughly cleaned and prevents any potential blockages or malfunctions. While individual parts can be cleaned separately, flushing the entire system is recommended to maintain the overall health of the lubrication system.

After completing a lubrication system overhaul, it is essential to use a high-quality lubricant that is recommended for the specific system and operating conditions. The type of lubricant to use can vary depending on factors such as temperature, pressure, and load requirements. It is crucial to follow the manufacturer's guidelines and recommendations when selecting the appropriate lubricant to ensure optimal performance and longevity of the system.

Performing a lubrication system overhaul may require specific tools and equipment to effectively complete the maintenance process. Some of the tools that may be needed include wrenches, sockets, oil filter wrenches, cleaning solvents, lubricants, and other specialized tools for disassembling and reassembling components. Having the necessary tools on hand can help streamline the overhaul process and ensure that the system is properly maintained.

The duration of a typical lubrication system overhaul can vary depending on the complexity of the system, the extent of maintenance required, and the availability of resources. In general, a lubrication system overhaul may take several hours to a full day to complete, depending on the thoroughness of the inspection, cleaning, and replacement of components. It is essential to allocate enough time for the overhaul to ensure that the system is properly maintained and functioning optimally.

Gearbox performance can indeed be affected by gearbox mounting issues. When the gearbox is not properly mounted, it can lead to misalignment, increased vibration, and premature wear on the gears and bearings. This can result in decreased efficiency, increased noise levels, and potential damage to other components within the transmission system. It is crucial to ensure that the gearbox is securely and accurately mounted to prevent any negative impacts on its overall performance and longevity. Regular maintenance and inspections of the gearbox mounting system are essential to avoid any potential issues that may arise from improper installation or mounting.

To prevent gearbox water ingress, several measures can be taken to ensure the integrity of the system. One effective method is to regularly inspect and maintain the gearbox seals to ensure they are in good condition and free from any cracks or damage. Additionally, applying a waterproof sealant or coating to vulnerable areas can help create an extra barrier against water penetration. Installing a breather vent with a filter can also help prevent moisture from entering the gearbox while still allowing for pressure equalization. Furthermore, ensuring proper drainage around the gearbox area can help prevent water from pooling and seeping into the system. Regularly monitoring the gearbox for any signs of water ingress, such as milky oil or corrosion, can also help detect any issues early on and prevent further damage.

Detecting gearbox oil oxidation can be done by monitoring the oil's color, viscosity, and odor. Oxidized gearbox oil may appear darker in color, have a thicker consistency, and emit a burnt or acrid smell. Additionally, testing the oil for acidity levels can also indicate oxidation. Other signs of gearbox oil oxidation include increased levels of sludge or varnish in the oil, decreased lubricating properties, and potential damage to the gearbox components. Regular oil analysis and maintenance can help prevent and detect gearbox oil oxidation before it causes significant damage to the system.

When troubleshooting gearbox clutch problems, it is important to first check for any signs of slipping, grinding, or difficulty shifting gears. Inspecting the clutch pedal for any unusual resistance or play can also provide valuable information. Additionally, examining the clutch fluid levels, clutch master cylinder, and clutch release bearing can help pinpoint the issue. Testing the clutch engagement and disengagement, as well as checking for any leaks or damage to the clutch components, can further aid in diagnosing the problem. It is recommended to consult a professional mechanic for a thorough inspection and proper diagnosis of gearbox clutch issues.

Gearbox lubrication failure can have severe consequences on the overall performance and longevity of a vehicle's transmission system. Without proper lubrication, the gears within the gearbox can experience increased friction, leading to excessive wear and tear. This can result in overheating, increased noise levels, and ultimately, mechanical failure. Additionally, inadequate lubrication can cause the gears to seize up or become misaligned, further compromising the functionality of the gearbox. In the long run, gearbox lubrication failure can lead to costly repairs or even the need for a full transmission replacement. Regular maintenance and monitoring of gearbox lubrication levels are essential to prevent these detrimental outcomes.

When troubleshooting gearbox cooling system problems, it is important to first check for any leaks in the system, such as from the transmission cooler or lines. Inspecting the radiator for any blockages or damage is also crucial. Additionally, checking the condition of the transmission fluid and ensuring it is at the correct level can help identify any issues. Testing the functionality of the thermostat, fan, and other cooling components can provide insight into potential malfunctions. It is recommended to consult the vehicle's manual for specific troubleshooting steps and to consider seeking professional assistance if needed. Regular maintenance and inspection of the gearbox cooling system can help prevent problems from occurring in the future.