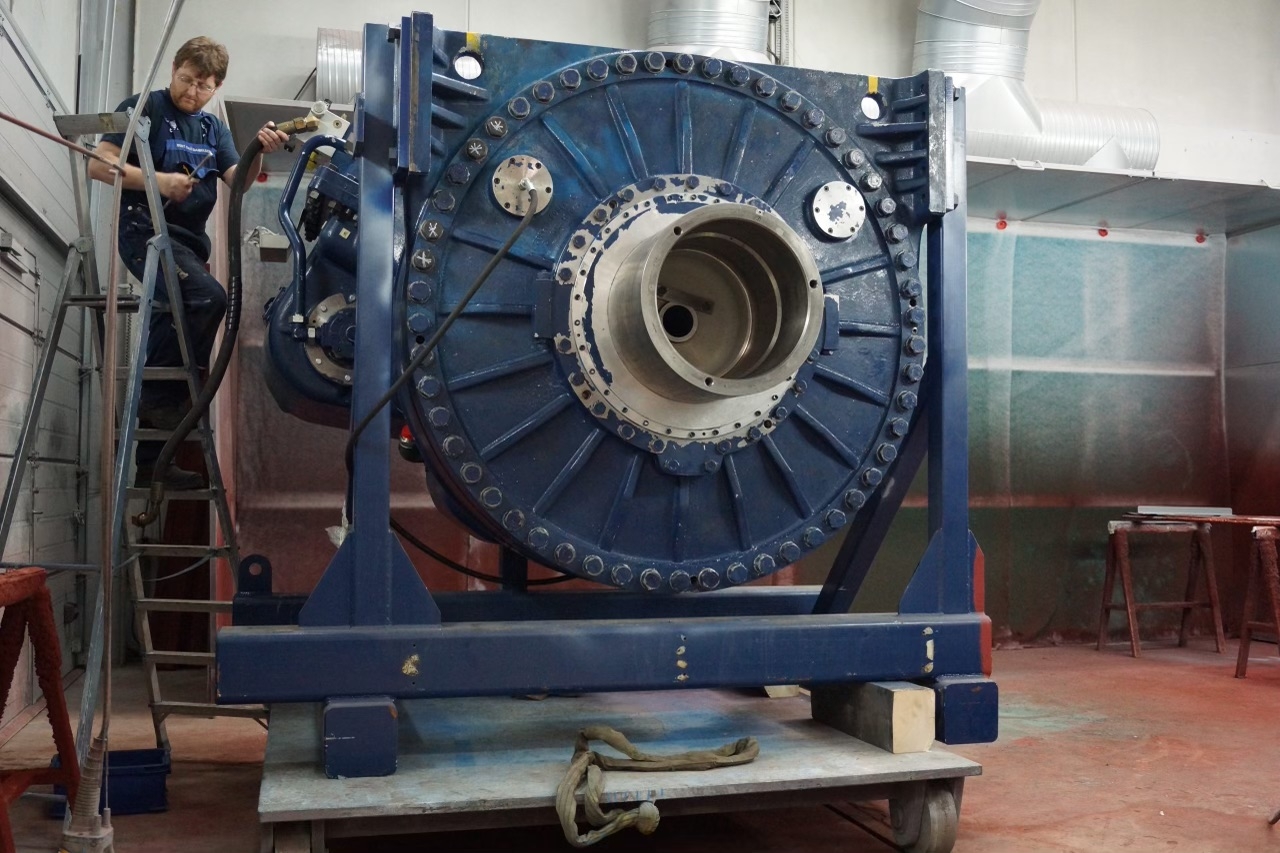

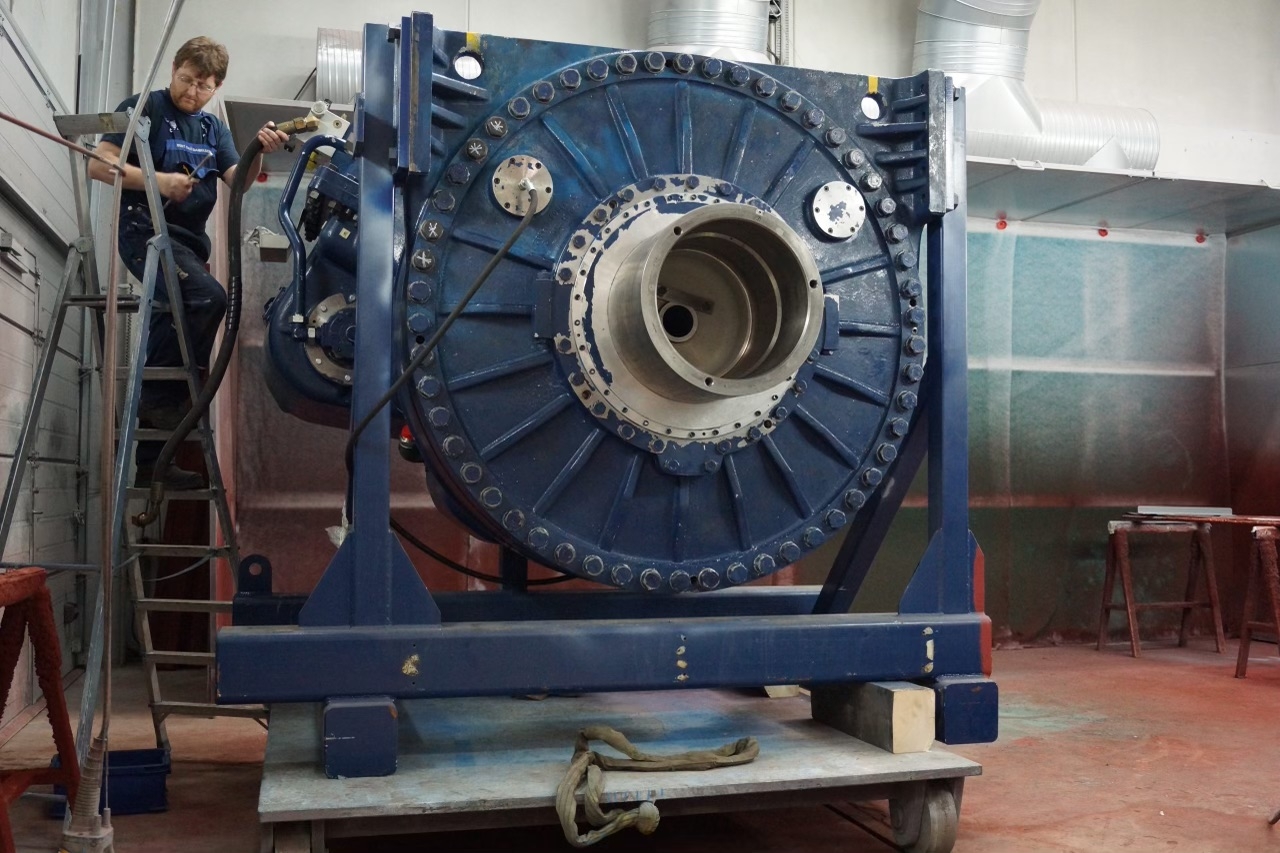

Gearbox lifting equipment differs from regular lifting equipment in its design and functionality. Gearbox lifting equipment is specifically designed to safely and efficiently lift and transport gearboxes, which are heavy and often awkwardly shaped machinery components. These specialized lifting devices are equipped with features such as adjustable arms, secure clamps, and precise controls to ensure the gearbox is lifted and moved with precision and care.

When using gearbox lifting equipment, key safety features to consider include overload protection mechanisms, emergency stop buttons, secure locking mechanisms, and anti-slip surfaces. These safety features are essential to prevent accidents, injuries, and damage to the gearbox or surrounding equipment. Regular inspections and maintenance of the lifting equipment are also crucial to ensure its safe operation.

More than 16,000 additional babies were born in Texas in 2022 compared to 2021 after the state banned almost all abortions after six weeks of pregnancy, according to a University of Houston analysis of 2022 fertility data.

Posted by on 2024-03-11

On Sunday, Maj. Gen. Ray Shields, the adjutant general of New York, said the bureau was mourning the deaths of Grassia, Frankoski and Luna.

Posted by on 2024-03-11

That major turnout comes as Rodeo Houston saw significantly lower attendance than last year's event nearing the halfway point last week.

Posted by on 2024-03-11

As the Houston Livestock Show and Rodeo wraps up, many are focused on the area's cowboy culture. Black cattle hands living just outside the city played a key part in that history.

Posted by on 2024-03-11

On Monday's show: We talk with NPR's White House Correspondent about the Republican National Convention, then we answer your questions about sleep and gardening--separately, of course.

Posted by on 2024-03-11

While gearbox lifting equipment is primarily designed for lifting gearboxes, it can also be used for lifting other types of machinery with similar weight and size characteristics. However, it is important to ensure that the equipment is compatible with the specific machinery being lifted and that the weight capacity of the lifting device is not exceeded to prevent accidents or damage.

When selecting gearbox lifting equipment, the weight capacity is a critical factor to consider. The equipment should be able to safely lift and transport the weight of the gearbox without exceeding its maximum capacity. It is important to accurately determine the weight of the gearbox and choose lifting equipment that can handle that weight with ease.

Gearbox lifting equipment must meet specific regulations and standards to ensure its safety and reliability. These regulations may vary depending on the industry and location, but common standards include OSHA requirements, ANSI standards, and manufacturer guidelines. It is important to verify that the gearbox lifting equipment complies with these regulations before use.

Gearbox lifting equipment can help improve efficiency in industrial settings by streamlining the process of lifting and moving heavy gearboxes. By using specialized lifting devices, workers can safely and quickly transport gearboxes to different locations within a facility, reducing the risk of injuries and minimizing downtime. This increased efficiency can lead to cost savings and improved productivity.

Common maintenance requirements for gearbox lifting equipment include regular inspections, lubrication of moving parts, checking for wear and tear, and ensuring that all safety features are functioning properly. It is important to follow the manufacturer's guidelines for maintenance and to address any issues promptly to prevent accidents or equipment failure. By properly maintaining gearbox lifting equipment, its longevity and safety can be ensured.

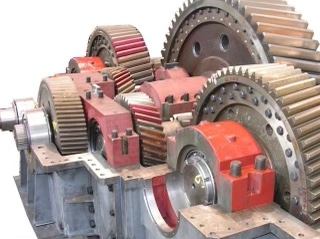

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

When interpreting gearbox temperature readings, it is important to consider various factors such as the operating conditions, lubrication system efficiency, ambient temperature, and the type of gearbox being used. High gearbox temperatures could indicate issues such as inadequate lubrication, overloading, misalignment, or worn-out components. On the other hand, low temperatures may suggest insufficient load or poor heat dissipation. It is crucial to monitor temperature trends over time and compare them to manufacturer recommendations to ensure optimal performance and prevent potential damage. Regular maintenance and inspection can help identify and address any issues related to gearbox temperature readings.

In pharmaceutical applications, there are specific gearbox maintenance requirements that must be adhered to in order to ensure optimal performance and compliance with industry regulations. These requirements may include regular inspections, lubrication checks, and temperature monitoring to prevent contamination and ensure smooth operation. Additionally, proper documentation of maintenance activities and adherence to Good Manufacturing Practices (GMP) are essential in pharmaceutical settings to guarantee the safety and efficacy of products. It is crucial for pharmaceutical companies to work closely with gearbox manufacturers and maintenance professionals to develop a comprehensive maintenance plan tailored to their specific needs and requirements. Failure to properly maintain gearboxes in pharmaceutical applications can result in costly downtime, product recalls, and potential regulatory issues.

Gearbox noise analysis can be a complex process that requires specialized techniques to accurately diagnose and address issues. Some of the key methods used in gearbox noise analysis include vibration analysis, acoustic testing, modal analysis, and frequency spectrum analysis. These techniques allow engineers to identify specific sources of noise within the gearbox, such as gear meshing, bearing defects, or lubrication issues. By using advanced tools such as accelerometers, microphones, and spectrum analyzers, experts can pinpoint the root cause of the noise and develop targeted solutions to reduce or eliminate it. Additionally, computer-aided design (CAD) software can be used to simulate gearbox operation and predict potential noise issues before they occur. Overall, a combination of these specialized techniques is essential for effective gearbox noise analysis and troubleshooting.

Indicators of gearbox shaft misalignment can include abnormal vibrations, increased noise levels, overheating, premature wear on bearings, and decreased efficiency in the transmission system. Other signs may include irregular gear tooth wear, shaft breakage, and coupling misalignment. These issues can lead to further damage to the gearbox components and result in costly repairs if not addressed promptly. Regular monitoring and maintenance of the gearbox shaft alignment are essential to prevent these problems and ensure optimal performance of the machinery.

To assess gearbox efficiency losses, engineers typically utilize a combination of methods such as performance testing, thermography, vibration analysis, and oil analysis. Performance testing involves measuring input and output power to calculate efficiency, while thermography can identify areas of overheating indicating energy loss. Vibration analysis helps detect mechanical issues that may be causing inefficiencies, and oil analysis can reveal contamination or wear particles that could be impacting performance. By combining these techniques, engineers can accurately assess gearbox efficiency losses and identify areas for improvement.