When it comes to gearbox overhauls, there are several common signs that indicate the need for this maintenance. These signs include grinding or whining noises coming from the gearbox, difficulty shifting gears, leaking gearbox oil, and vibrations while driving. If you notice any of these symptoms, it is crucial to have your gearbox inspected by a professional to determine if an overhaul is necessary.

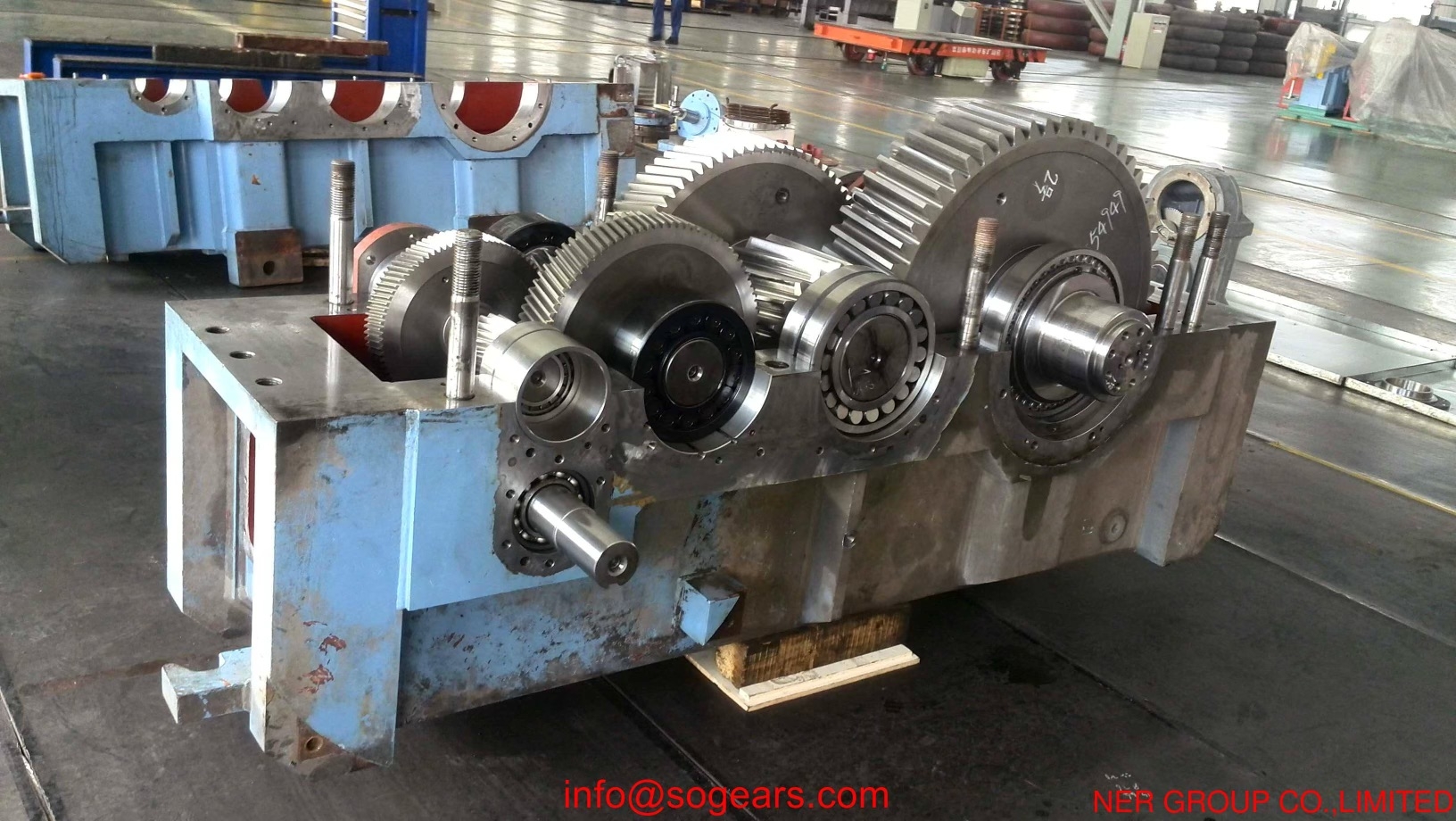

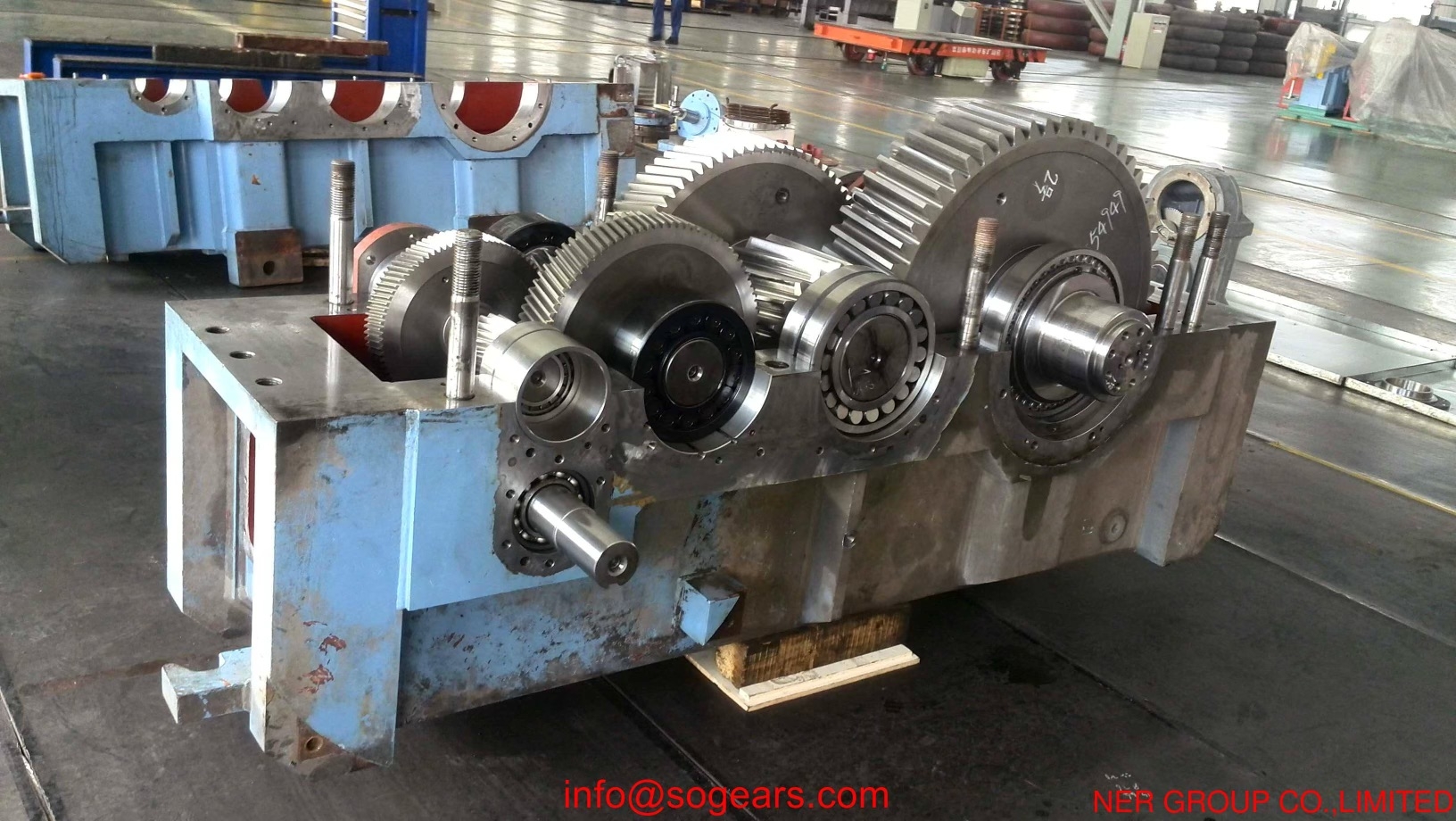

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

To prevent the need for a gearbox overhaul, it is recommended to change the gearbox oil regularly. The frequency of gearbox oil changes can vary depending on the vehicle manufacturer's recommendations, but typically it is advised to change the oil every 30,000 to 60,000 miles. By maintaining clean and fresh gearbox oil, you can help prolong the life of your gearbox and reduce the likelihood of needing a costly overhaul.

Each month, we turn to the Garden Club of Houston’s Meg Tapp to offer advice for Houston area gardeners.

Posted by on 2024-03-11

NFL free agency is underway, with teams able to negotiate with players now. They can start signing contracts Wednesday.

Posted by on 2024-03-11

Only about 40 minutes of footage made it out to the world in real time because of poor connections, but when Chernov and his colleagues were finally able to leave, he decided he needed to do something with the 30-some hours they had on tape.

Posted by on 2024-03-11

More than 16,000 additional babies were born in Texas in 2022 compared to 2021 after the state banned almost all abortions after six weeks of pregnancy, according to a University of Houston analysis of 2022 fertility data.

Posted by on 2024-03-11

On Sunday, Maj. Gen. Ray Shields, the adjutant general of New York, said the bureau was mourning the deaths of Grassia, Frankoski and Luna.

Posted by on 2024-03-11

During a gearbox overhaul, several main components are typically replaced to ensure the gearbox functions properly. These components may include bearings, seals, gaskets, synchros, and possibly gears themselves if they are worn or damaged. By replacing these key components, the gearbox can be restored to optimal working condition and prevent further issues down the road.

While some experienced mechanics may attempt a gearbox overhaul as a DIY project, it is generally best left to professionals. Gearboxes are complex systems that require specialized knowledge and tools to disassemble, inspect, and reassemble properly. A professional mechanic will have the expertise and experience to perform a gearbox overhaul correctly, reducing the risk of errors or complications.

Performing a gearbox overhaul requires specific tools and equipment to ensure the job is done correctly. Some of the tools that may be needed include torque wrenches, bearing pullers, snap ring pliers, and gear pullers. Additionally, specialized equipment such as a gearbox jack or stand may be necessary to safely remove and reinstall the gearbox from the vehicle. Having the right tools and equipment is essential for a successful gearbox overhaul.

The duration of a typical gearbox overhaul can vary depending on the extent of the damage and the complexity of the gearbox system. In general, a gearbox overhaul can take anywhere from a few days to a week to complete. This timeframe allows for thorough inspection, replacement of components, and proper reassembly to ensure the gearbox functions correctly once the overhaul is finished.

While gearbox overhauls can be beneficial in restoring a gearbox to optimal condition, there are potential risks and complications that can arise during the process. These risks may include incorrect reassembly leading to gearbox malfunctions, damage to other components during disassembly, or the discovery of additional issues that require further repairs. To mitigate these risks, it is essential to have the gearbox overhaul performed by a qualified professional with experience in gearbox maintenance and repair.

Balancing can indeed enhance the performance of a gearbox by optimizing the distribution of weight and reducing vibrations that can lead to wear and tear. By carefully adjusting the mass distribution of the components within the gearbox, engineers can improve its efficiency, durability, and overall functionality. This process involves precision machining, dynamic balancing, and the use of specialized tools and techniques to ensure that all parts work together seamlessly. Additionally, balancing can help minimize noise levels, increase power transmission, and extend the lifespan of the gearbox. Overall, balancing plays a crucial role in enhancing gearbox performance and ensuring smooth operation in various applications.

When it comes to gearbox maintenance, there are several specialized tools that can be used to ensure optimal performance and longevity. Some of these tools include gear pullers, bearing pullers, torque wrenches, dial indicators, and gear shimming tools. Gear pullers are used to remove gears from shafts, while bearing pullers are used to remove bearings from gearboxes. Torque wrenches are essential for tightening bolts to the correct specifications, while dial indicators are used to measure gear backlash and runout. Gear shimming tools are used to adjust the spacing between gears for proper meshing. These specialized tools are designed to make gearbox maintenance easier and more efficient, ultimately helping to prevent costly repairs and downtime.

The efficiency of a gearbox can indeed be influenced by the material used for the gearbox housing. The choice of material can impact factors such as heat dissipation, weight, durability, and overall performance. For example, using lightweight materials like aluminum or magnesium can improve the efficiency by reducing the overall weight of the gearbox, leading to less energy loss during operation. Additionally, materials with good thermal conductivity can help dissipate heat more effectively, preventing overheating and improving overall efficiency. On the other hand, using materials with poor durability or high friction coefficients can negatively affect the gearbox's efficiency by increasing wear and energy loss. Therefore, selecting the appropriate gearbox housing material is crucial in optimizing the efficiency and performance of the gearbox.

Gearbox seals can indeed degrade over time due to various factors such as exposure to heat, friction, and contaminants. The material composition of the seals, including rubber or silicone, can break down over time, leading to cracks, leaks, and overall deterioration. Additionally, environmental conditions, such as temperature fluctuations and moisture, can also contribute to the degradation of gearbox seals. Regular maintenance and inspection of seals are crucial to ensure optimal performance and prevent potential issues with the gearbox system. It is important to replace worn-out seals promptly to avoid more significant damage to the gearbox components.