The design of a gearbox cooling system plays a crucial role in the overall efficiency of the system. An efficient cooling system ensures that the gearbox operates within the optimal temperature range, preventing overheating and potential damage to the components. The design should consider factors such as the size and placement of heat exchangers, the type of cooling method used, and the airflow within the system to effectively dissipate heat and maintain the desired temperature levels.

Gearbox cooling systems utilize various cooling methods to dissipate heat generated during operation. Some common types include air cooling, oil cooling, and water cooling. Air cooling systems use fans to circulate air around the gearbox, while oil cooling systems use oil as a coolant to absorb and transfer heat away from the components. Water cooling systems involve circulating water through a heat exchanger to remove heat from the gearbox. Each method has its advantages and is chosen based on the specific requirements of the gearbox.

The cinema showed films for 64 continuous years, making it one of the longest-running theatres in the country.

Posted by on 2024-03-13

On Wednesday's show: We discuss the latest developments in politics, including whether runoffs ever have dramatically different results. Then we consider if we are ready for the next major public health emergency.

Posted by on 2024-03-13

Episode: 2998 Test Tube Evolution. Today, evolution in a test tube.

Posted by on 2024-03-13

Dr. Talat Jehan Khan, a pediatrician for Texas Children's Hospital, was stabbed to death Oct. 28 in an outdoor common area at Alys Luxury Living in Conroe. The man accused of killing her is jailed and faces a murder charge.

Posted by on 2024-03-12

Temperature sensors are essential components in monitoring and controlling the temperature of a gearbox cooling system. These sensors provide real-time data on the temperature levels within the system, allowing for adjustments to be made to maintain optimal operating conditions. By continuously monitoring the temperature, temperature sensors help prevent overheating and ensure the gearbox operates efficiently and safely.

Common issues that can arise in gearbox cooling systems include clogging of filters, leaks in the cooling system, and insufficient cooling capacity. To prevent these problems, regular maintenance and inspection of the system are necessary. Filters should be cleaned or replaced regularly to maintain proper airflow, leaks should be repaired promptly, and the cooling capacity should be adequate for the heat generated by the gearbox.

The lubrication system in a gearbox cooling system plays a critical role in its overall performance and longevity. Proper lubrication helps reduce friction between moving parts, which in turn reduces heat generation. This not only improves the efficiency of the gearbox but also extends the lifespan of the components. Regular maintenance of the lubrication system, including oil changes and inspections, is essential to ensure smooth operation and prevent premature wear and tear.

Filters are an integral part of maintaining the cleanliness and effectiveness of a gearbox cooling system. Filters help remove contaminants such as dirt, debris, and metal particles from the cooling fluid, preventing them from circulating through the system and causing damage to the components. Regularly checking and replacing filters is crucial to ensure that the cooling system operates efficiently and effectively.

The size and placement of heat exchangers can significantly affect the cooling capacity of a gearbox cooling system. Properly sized heat exchangers with sufficient surface area can efficiently dissipate heat from the gearbox, preventing overheating and ensuring optimal performance. Additionally, the placement of heat exchangers within the system should allow for adequate airflow and heat transfer to effectively cool the components. By optimizing the size and placement of heat exchangers, the cooling capacity of the gearbox cooling system can be maximized.

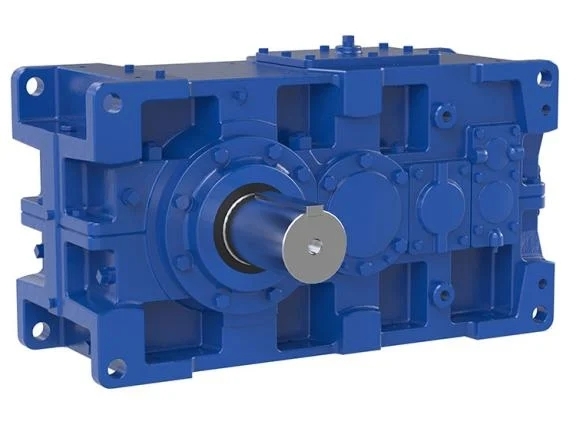

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

When selecting the appropriate gearbox for an industrial application, it is crucial to consider various factors such as torque requirements, speed ratios, efficiency, backlash, and mounting options. The type of gearbox, whether it be helical, worm, planetary, or bevel, should be chosen based on the specific needs of the application. Additionally, factors such as load capacity, operating environment, maintenance requirements, and cost should also be taken into consideration. It is important to consult with a knowledgeable engineer or gearbox specialist to ensure that the chosen gearbox will meet the requirements of the industrial application and provide optimal performance and longevity.

The main causes of gearbox overheating can be attributed to a variety of factors, including excessive friction within the gears, inadequate lubrication, high operating speeds, overloading, and poor ventilation. When gears rub against each other without proper lubrication, the resulting friction generates heat, leading to overheating. Additionally, operating the gearbox at high speeds or overloading it beyond its capacity can also contribute to increased heat generation. Inadequate ventilation within the gearbox can further exacerbate the problem by trapping heat and preventing proper cooling. Regular maintenance, proper lubrication, and ensuring the gearbox is operated within its specified limits can help prevent overheating issues.

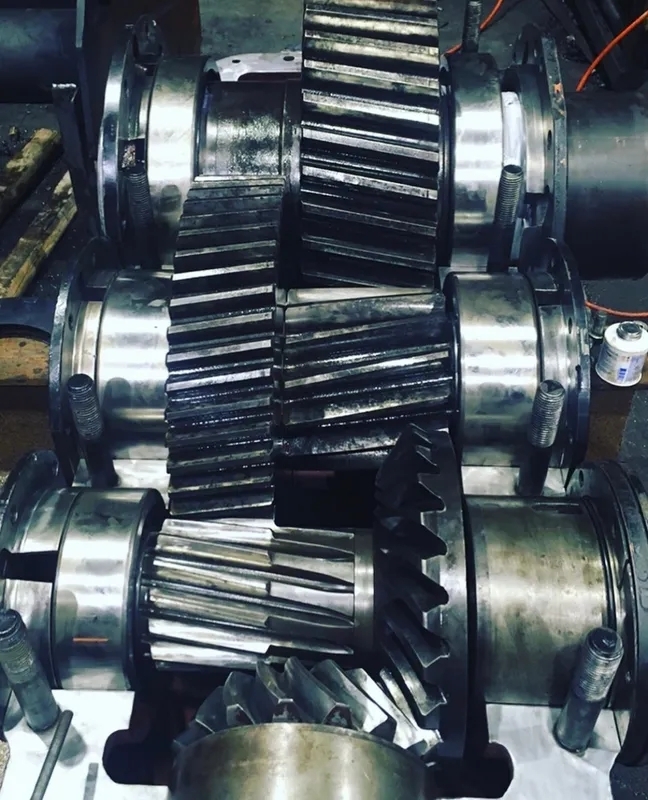

Repairing gearbox gear teeth is indeed possible through a process known as gear tooth restoration. This involves techniques such as gear tooth welding, gear tooth reshaping, and gear tooth grinding to repair any damage or wear on the teeth. Specialized equipment and skilled technicians are required to perform these repairs effectively. Additionally, the use of high-quality materials and precise measurements are crucial to ensure the repaired gear teeth function properly and maintain the overall integrity of the gearbox. It is important to address any issues with gear teeth promptly to prevent further damage and ensure the gearbox operates smoothly and efficiently.

When addressing gearbox gear tooth chipping, it is important to first identify the root cause of the issue. Common causes of gear tooth chipping include misalignment, overloading, inadequate lubrication, and material defects. To address this issue, one can consider implementing measures such as adjusting alignment, reducing load, improving lubrication systems, and using higher quality materials. Regular maintenance and inspection of the gearbox can also help prevent gear tooth chipping in the future. Additionally, seeking the expertise of a professional engineer or technician specializing in gearbox maintenance may provide valuable insights and solutions to effectively address this problem.

When addressing gearbox oil foaming issues, it is important to first identify the root cause of the problem. Common causes of gearbox oil foaming include high operating temperatures, improper oil levels, air leaks in the system, and excessive agitation of the oil. To resolve this issue, one can consider using anti-foaming additives, ensuring proper oil levels, fixing any air leaks, and reducing the amount of agitation in the system. Regular maintenance and monitoring of the gearbox can also help prevent foaming issues from occurring in the future. By taking these steps, one can effectively address gearbox oil foaming problems and ensure smooth operation of the equipment.