The hardness of gearbox components plays a crucial role in determining their durability and performance. Components with higher hardness levels are more resistant to wear, abrasion, and deformation, resulting in a longer lifespan and improved overall performance of the gearbox. On the other hand, components with lower hardness levels are more prone to damage and may lead to premature failure of the gearbox system.

There are several methods used to test the hardness of gearbox components, including Rockwell hardness testing, Brinell hardness testing, Vickers hardness testing, and Knoop hardness testing. Each method has its own advantages and is suitable for different types of materials and component shapes. These tests help manufacturers ensure that gearbox components meet the required hardness standards for optimal performance.

Houston ISD is again embroiled in internal strife and public controversy. On Friday, the district released performance ratings to principals. After the Houston Chronicle published details about the ratings, the administration suggested the possibility of legal action against the news outlet and launched an investigation to find the source of the leak.

Posted by on 2024-03-11

Episode: 1132 In which balloons deliver the mail during the Siege of Paris. Today, the very first airmail service is used to break a siege.

Posted by on 2024-03-11

Episode: 1131 John Hunter: idiosyncratic medical pioneer. Today, the history of medicine provides a strange hero.

Posted by on 2024-03-10

Episode: 1129 In which Alphonse Penaud invents the model airplane. Today, a very young man teaches us to fly, after all.

Posted by on 2024-03-09

The new fiscal year begins in July and the city is anticipating a budgetary gap of about $160 million.

Posted by on 2024-03-08

The hardness of gearbox components can be adjusted or modified during the manufacturing process through various heat treatment techniques such as carburizing, nitriding, and induction hardening. These processes can increase the hardness of the components to improve their wear resistance and overall performance. Manufacturers carefully control the hardness levels to meet specific requirements and standards.

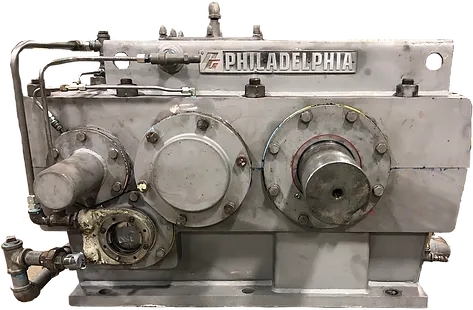

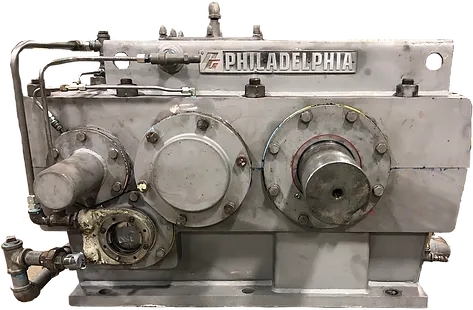

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

Rockwell hardness testing is particularly significant for gearbox components as it provides a reliable and accurate measurement of hardness. This testing method involves applying a specific load to the component surface and measuring the depth of penetration, which is then converted into a hardness value. Rockwell hardness testing is widely used in the industry to assess the hardness of gearbox components and ensure they meet the necessary specifications.

The hardness of gearbox components directly impacts their resistance to wear and tear. Components with higher hardness levels are more resistant to friction, impact, and other forms of mechanical stress, resulting in reduced wear and longer service life. Proper hardness levels are essential for maintaining the integrity and functionality of gearbox components under demanding operating conditions.

There are specific industry standards and regulations regarding the hardness testing of gearbox components to ensure quality and reliability. Organizations such as the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) have established guidelines for hardness testing methods and acceptance criteria for gearbox components. Manufacturers must adhere to these standards to meet industry requirements and ensure product quality.

Hardness testing plays a critical role in quality control and assurance for gearbox components. By accurately measuring the hardness of components, manufacturers can verify their mechanical properties and ensure they meet the specified requirements for performance and durability. Regular hardness testing during the manufacturing process helps identify any deviations or defects early on, allowing for corrective actions to be taken to maintain the quality of gearbox components.

Preventing gearbox oil contamination from water can be achieved through various measures. One effective method is to ensure proper sealing of the gearbox to prevent water ingress. Regular maintenance and inspection of seals, gaskets, and O-rings can help identify any potential leaks that may allow water to enter the gearbox. Additionally, using high-quality gearbox oil with water-resistant properties can help mitigate the risk of contamination. Implementing a regular oil change schedule can also prevent water buildup in the gearbox. Furthermore, storing the gearbox in a dry and controlled environment can help minimize the chances of water contamination. Overall, a combination of preventive measures such as proper sealing, maintenance, oil selection, and storage practices can help safeguard the gearbox from water contamination.

Gearbox maintenance procedures for wind turbine applications typically involve regular inspections, lubrication checks, and vibration analysis to ensure optimal performance and prevent potential failures. Specific tasks may include monitoring oil levels, changing filters, inspecting gear teeth for wear, and tightening bolts to prevent loosening. Additionally, technicians may conduct thermographic inspections to detect overheating components and perform oil analysis to identify any contaminants or signs of degradation. By following these detailed maintenance procedures, wind turbine operators can prolong the lifespan of their gearboxes and minimize downtime due to unexpected malfunctions.

When performing gearbox repair, it is important to follow specific safety precautions to prevent accidents and injuries. Some of these precautions include wearing appropriate personal protective equipment such as gloves, safety glasses, and steel-toed boots. It is also important to work in a well-ventilated area to avoid exposure to harmful fumes or gases. Additionally, using proper tools and equipment, following manufacturer guidelines, and ensuring the gearbox is properly supported during repair are all essential safety measures. Regular maintenance and inspections of gearboxes can help identify potential issues before they become safety hazards. Overall, following these safety precautions can help ensure a successful and safe gearbox repair process.

The process of gearbox disassembly involves several steps that must be followed carefully to ensure the successful removal of components. First, the technician must drain the gearbox of any fluids and remove the external casing. Next, they will need to disconnect any electrical connections and remove any mounting bolts or brackets holding the gearbox in place. Once the gearbox is free from its mounting, the technician can begin to disassemble the internal components, such as gears, bearings, and shafts. Each component must be carefully removed and inspected for any signs of wear or damage. Finally, once all components have been removed, the technician can clean and inspect each part before reassembly. Following these steps will ensure a thorough gearbox disassembly process.