Bearing preload in gearbox applications is typically measured by applying a specific load or torque to the bearings and then measuring the resulting displacement or deflection. This measurement helps ensure that the bearings are properly preloaded to optimize performance and prevent issues such as excessive noise or premature wear.

Different techniques can be used to measure bearing preload in gearboxes, including using specialized tools such as dial indicators or torque wrenches. These tools allow technicians to accurately apply and measure the preload force on the bearings to ensure they are within the specified tolerance range.

“I was prepared to roll out some improvements and reforms, but was unsatisfied with the product that I received from Public Works yesterday,” said Mayor Whitmire during Tuesday’s public session meeting. “So I sent them back to the drawing board.”

Posted by on 2024-03-11

Houston officials and community members are touting the success of the barricades they say have driven away prostitutes and those actively seeking them.

Posted by on 2024-03-11

The 54-year-old Anderson, known for feature-length films such as "Rushmore," "The Royal Tenenbaums," "Fantastic Mr. Fox" and "Asteroid City," won in the Best Live Action Short Film category for "The Wonderful Story of Henry Sugar." He had previously been nominated for seven Academy Awards.

Posted by on 2024-03-11

Attorney General Ken Paxton has now targeted seven school districts over alleged electioneering in what he calls an effort to stop elections from being “illegally swayed by public officials improperly using state resources.” Those school districts are responding.

Posted by on 2024-03-11

In some cases, bearing preload can be adjusted after measurement in gearboxes by either increasing or decreasing the preload force applied to the bearings. This adjustment may be necessary to fine-tune the performance of the gearbox or address any issues that arise during operation.

Bearing preload plays a crucial role in gearbox performance by ensuring that the bearings are properly seated and loaded to handle the expected forces and speeds. Proper preload helps reduce vibration, noise, and wear, while also improving the overall efficiency and lifespan of the gearbox.

Specific tools are required for measuring bearing preload in gearboxes, such as dial indicators, torque wrenches, and bearing preload gauges. These tools are designed to accurately apply and measure the preload force on the bearings to ensure they are within the specified tolerance range for optimal performance.

The amount of bearing preload can significantly affect gearbox efficiency, as insufficient preload can lead to excessive clearance and increased wear, while excessive preload can cause added friction and reduced efficiency. Finding the right balance is crucial for maximizing the performance and longevity of the gearbox.

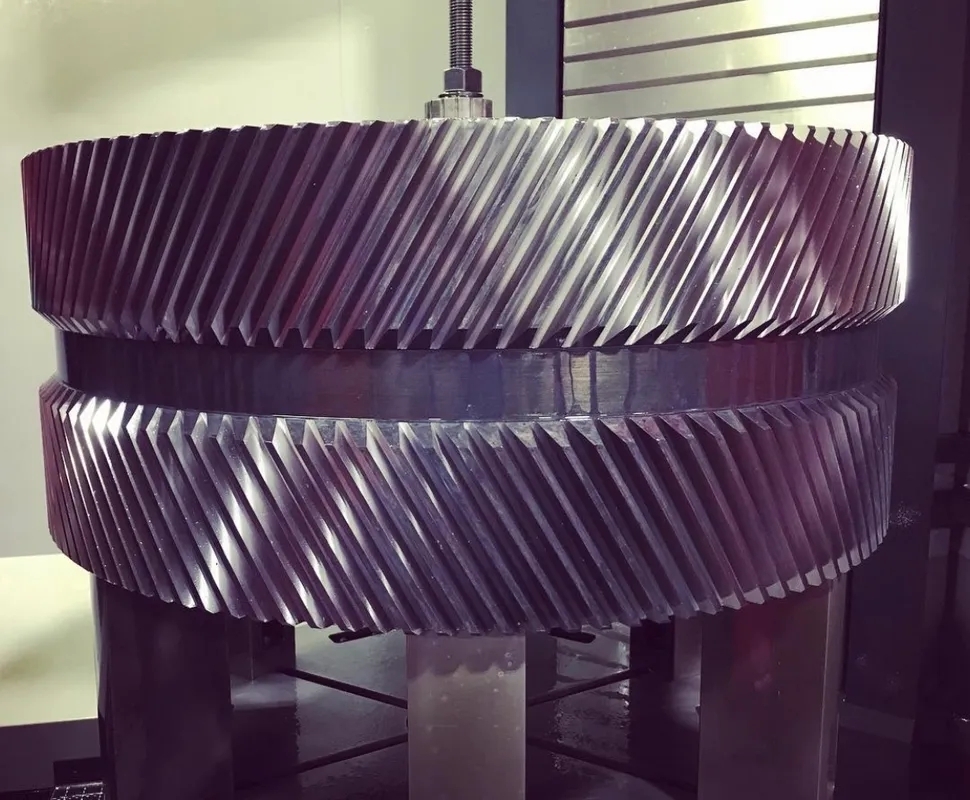

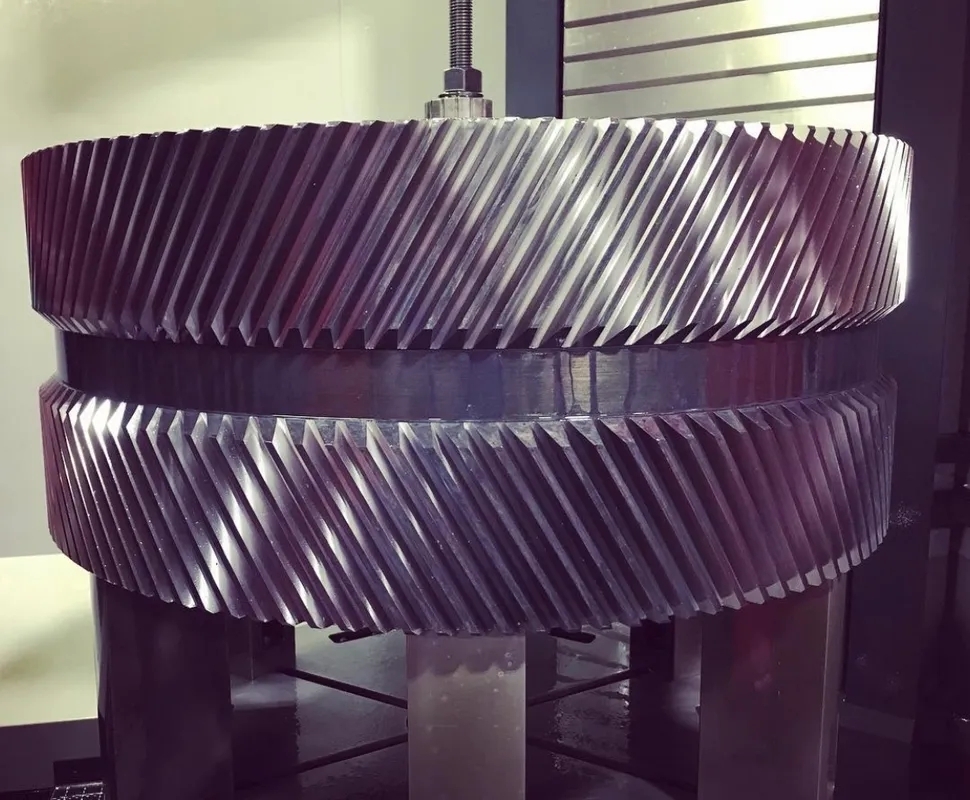

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

Incorrect bearing preload in gearboxes can have several potential consequences, including increased noise, vibration, and wear, as well as reduced efficiency and lifespan. It can also lead to premature failure of the bearings or other components within the gearbox, resulting in costly repairs and downtime. Therefore, it is essential to carefully measure and adjust bearing preload to ensure optimal performance and reliability of the gearbox.

When determining the appropriate gearbox lubricant volume, it is important to consider factors such as gear type, operating conditions, and manufacturer recommendations. The volume of lubricant needed will vary depending on the size and design of the gearbox, as well as the speed and load at which it operates. It is crucial to consult the gearbox manual or contact the manufacturer to determine the correct lubricant volume for optimal performance and longevity. Additionally, factors such as temperature, viscosity, and oil type should be taken into account when calculating the appropriate volume of lubricant to ensure proper lubrication and protection of the gearbox components. Regular maintenance and monitoring of the lubricant level are also essential to prevent damage and ensure smooth operation of the gearbox.

When addressing gearbox lubrication blockages, it is important to first identify the root cause of the issue. Common reasons for blockages include contamination, inadequate lubrication, or mechanical failures. To resolve the blockage, one can utilize methods such as flushing the system, replacing the lubricant, cleaning filters, or repairing any damaged components. It is crucial to follow manufacturer guidelines and use appropriate tools and equipment to ensure proper maintenance and prevent future blockages. Regular inspections and maintenance routines can help detect and address blockages before they escalate into more severe problems. By addressing gearbox lubrication blockages promptly and effectively, one can ensure optimal performance and longevity of the equipment.

One way to identify gearbox seal leaks is to look for signs of oil or fluid dripping or pooling underneath the vehicle. Other indicators may include a decrease in fluid levels, visible cracks or damage to the seal itself, and a burning smell coming from the gearbox. Additionally, a visual inspection of the gearbox housing and surrounding components may reveal signs of leakage, such as oil stains or residue. It is important to address gearbox seal leaks promptly to prevent further damage to the transmission system and ensure optimal performance of the vehicle.

Filtration systems play a crucial role in gearbox maintenance by removing contaminants such as dirt, debris, and metal particles from the lubricating oil. These systems help prevent wear and tear on gearbox components, improve overall performance, and extend the lifespan of the gearbox. By capturing and filtering out harmful particles, filtration systems ensure that the lubricating oil remains clean and effective in reducing friction and heat within the gearbox. Regular maintenance of filtration systems is essential to ensure optimal gearbox performance and prevent costly repairs or replacements. Proper filtration also helps maintain the viscosity and integrity of the lubricating oil, ensuring smooth operation and efficient power transmission within the gearbox.