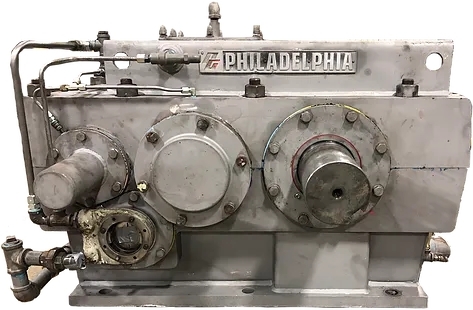

The process involved in reconditioning gearbox components typically includes disassembling the gearbox, inspecting each component for wear and damage, replacing any worn or damaged parts, cleaning all components thoroughly, reassembling the gearbox, and testing it to ensure proper functionality. This meticulous process helps to restore the gearbox components to their optimal condition, improving performance and longevity.

Reconditioning services can improve the performance of gearbox components by addressing any wear or damage that may be affecting their functionality. By replacing worn parts, cleaning components, and ensuring proper assembly, reconditioning can help optimize the efficiency and reliability of gearbox components, ultimately enhancing the overall performance of the gearbox.

Attorney General Ken Paxton has now targeted seven school districts over alleged electioneering in what he calls an effort to stop elections from being “illegally swayed by public officials improperly using state resources.” Those school districts are responding.

Posted by on 2024-03-11

Shead was the only unanimous pick on the first team announced Sunday.

Posted by on 2024-03-11

Each month, we turn to the Garden Club of Houston’s Meg Tapp to offer advice for Houston area gardeners.

Posted by on 2024-03-11

NFL free agency is underway, with teams able to negotiate with players now. They can start signing contracts Wednesday.

Posted by on 2024-03-11

Only about 40 minutes of footage made it out to the world in real time because of poor connections, but when Chernov and his colleagues were finally able to leave, he decided he needed to do something with the 30-some hours they had on tape.

Posted by on 2024-03-11

Common signs that gearbox components may need reconditioning include unusual noises coming from the gearbox, difficulty shifting gears, leaks of fluid from the gearbox, and decreased performance or efficiency. These signs may indicate that certain components within the gearbox are worn or damaged and would benefit from reconditioning to restore optimal functionality.

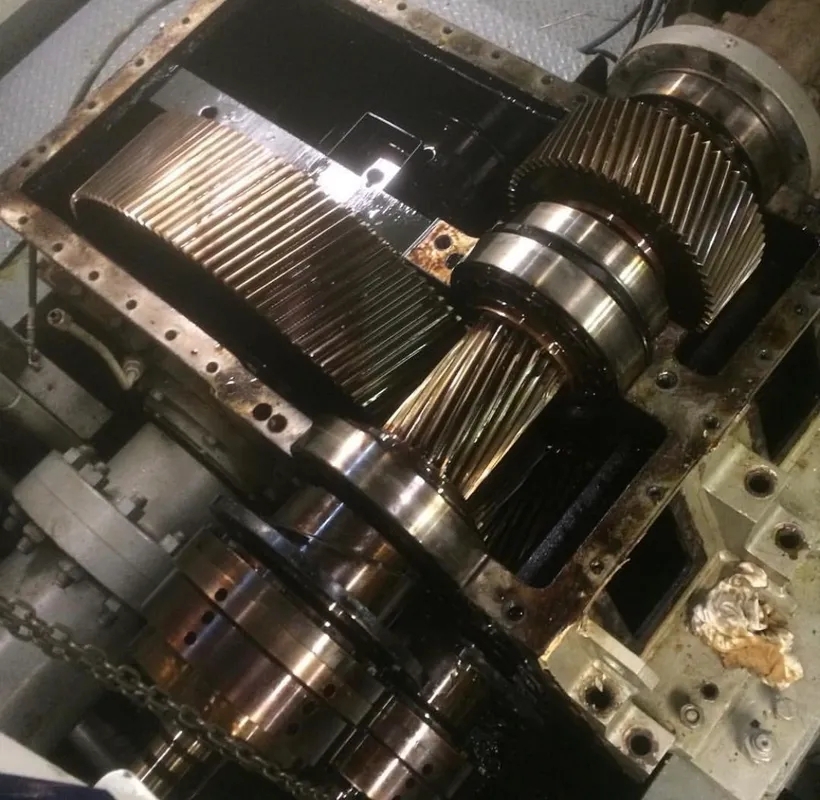

Certain types of gearbox components are more commonly reconditioned than others, such as gears, bearings, seals, and shafts. These components are often subject to wear and tear due to the nature of their function within the gearbox, making them prime candidates for reconditioning to ensure smooth operation and prevent further damage to the gearbox as a whole.

The time it takes to recondition gearbox components can vary depending on the extent of wear and damage, the availability of replacement parts, and the complexity of the gearbox itself. In general, reconditioning gearbox components can take anywhere from a few days to a couple of weeks, as thorough inspection, replacement, cleaning, and testing are necessary steps in the process.

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

Choosing reconditioning services over replacing gearbox components entirely can offer several benefits, including cost savings, reduced downtime, and the preservation of original components. Reconditioning allows for the restoration of existing components to like-new condition, often at a fraction of the cost of purchasing new parts, while also minimizing the need for extensive repairs or replacements.

To prolong the lifespan of reconditioned gearbox components, it is important to follow proper maintenance practices, such as regular inspections, fluid changes, and lubrication. By keeping the gearbox well-maintained and addressing any issues promptly, you can help ensure the continued performance and longevity of reconditioned components. Additionally, following manufacturer recommendations for maintenance intervals and procedures can help optimize the efficiency and reliability of the gearbox over time.

When addressing gearbox gear tooth wear, it is important to first identify the root cause of the issue. Common factors that contribute to gear tooth wear include improper lubrication, misalignment, overloading, and poor gear meshing. To mitigate wear, one can implement regular maintenance schedules, use high-quality lubricants, ensure proper alignment of gears, and monitor load distribution. Additionally, utilizing advanced technologies such as vibration analysis and thermography can help detect early signs of wear and prevent further damage. By addressing these factors proactively, one can extend the lifespan of gearbox gears and optimize their performance.

To prevent gearbox oil foaming during operation, several measures can be taken. Firstly, ensuring the gearbox is filled with the correct type and amount of oil can help prevent foaming. Additionally, maintaining proper oil levels and changing the oil at recommended intervals can also reduce the likelihood of foaming. Using high-quality oil with anti-foaming additives can further prevent foaming during operation. Proper ventilation and cooling of the gearbox can also help reduce the risk of foaming. Regular inspection of the gearbox for any leaks or damage that could lead to foaming is essential. Overall, following manufacturer guidelines and best practices for gearbox maintenance can help prevent oil foaming during operation.

Proper gearbox storage when not in use is essential to maintain its functionality and longevity. The best practices include cleaning the gearbox thoroughly to remove any dirt or debris, applying a protective coating to prevent corrosion, and storing it in a dry and temperature-controlled environment to prevent moisture damage. It is also recommended to rotate the gearbox periodically to prevent any parts from seizing up. Additionally, storing the gearbox in its original packaging or a protective case can help prevent any accidental damage. Following these guidelines will ensure that the gearbox remains in optimal condition for future use.

After assembly, it is crucial to follow best practices for gearbox inspection to ensure optimal performance and longevity. The first step is to visually inspect the gearbox for any signs of damage, such as cracks, leaks, or misalignments. Next, the technician should check the gear teeth for wear, pitting, or chipping, as well as the bearings for any signs of overheating or excessive play. It is also important to verify that all fasteners are properly tightened and that the lubrication levels are adequate. Additionally, conducting a thorough run-in procedure to ensure proper meshing of gears and smooth operation is recommended. Finally, performing vibration analysis and noise level testing can help identify any potential issues before they escalate. By following these best practices, technicians can catch any problems early on and prevent costly repairs or downtime.