When selecting a material for gearbox housing, key factors to consider include the material's durability, impact resistance, thermal conductivity, and machinability. The material chosen should be able to withstand the stresses and forces experienced during gearbox operation, while also being able to be easily manufactured into the required shape and size. Additionally, factors such as cost, weight, and corrosion resistance should also be taken into account to ensure the overall performance and longevity of the gearbox.

The operating temperature plays a crucial role in the choice of material for gearbox housing. Materials with high thermal conductivity and heat resistance are preferred for applications where the gearbox will be exposed to high temperatures. It is important to select a material that can maintain its mechanical properties and structural integrity under the specific operating conditions to prevent premature failure or damage to the gearbox components.

The university is partnering with the Ibn Sina Foundation and the OakBend Medical Center in Richmond.

Posted by on 2024-03-12

It's allergy season in Houston, and many are feeling its impact. But allergist Dr. Dat Tran said the pollen count is low compared to 2023.

Posted by on 2024-03-12

A temporary hold on the law was set to expire Wednesday, but the high court extended the pause.

Posted by on 2024-03-12

The Esperanza "Hope" Andrade, named after a former Texas Secretary of State, is the first boat at the Galveston Ferry to be named after a woman and the first in Texas to be named after a Latina, according to TxDOT.

Posted by on 2024-03-12

The mechanical strength of a material is a critical factor in gearbox housing selection. The material chosen should have sufficient tensile strength, yield strength, and impact resistance to withstand the loads and forces exerted on the gearbox during operation. High mechanical strength ensures the gearbox housing can effectively protect the internal components and maintain its structural integrity under various operating conditions.

The weight of the material used for gearbox housing can impact the overall performance of the gearbox. Lightweight materials can help reduce the overall weight of the gearbox assembly, leading to improved fuel efficiency, reduced energy consumption, and enhanced vehicle performance. However, it is essential to balance weight savings with the required mechanical strength and durability to ensure the gearbox housing can withstand the operational stresses and forces.

Aluminum is a popular choice for gearbox housing due to its lightweight, corrosion resistance, and ease of machining. It offers good thermal conductivity and can be easily formed into complex shapes, making it suitable for gearbox applications where weight reduction and heat dissipation are important. However, aluminum may not have the same level of mechanical strength as other materials like steel, which could impact the durability and longevity of the gearbox housing in certain high-stress environments.

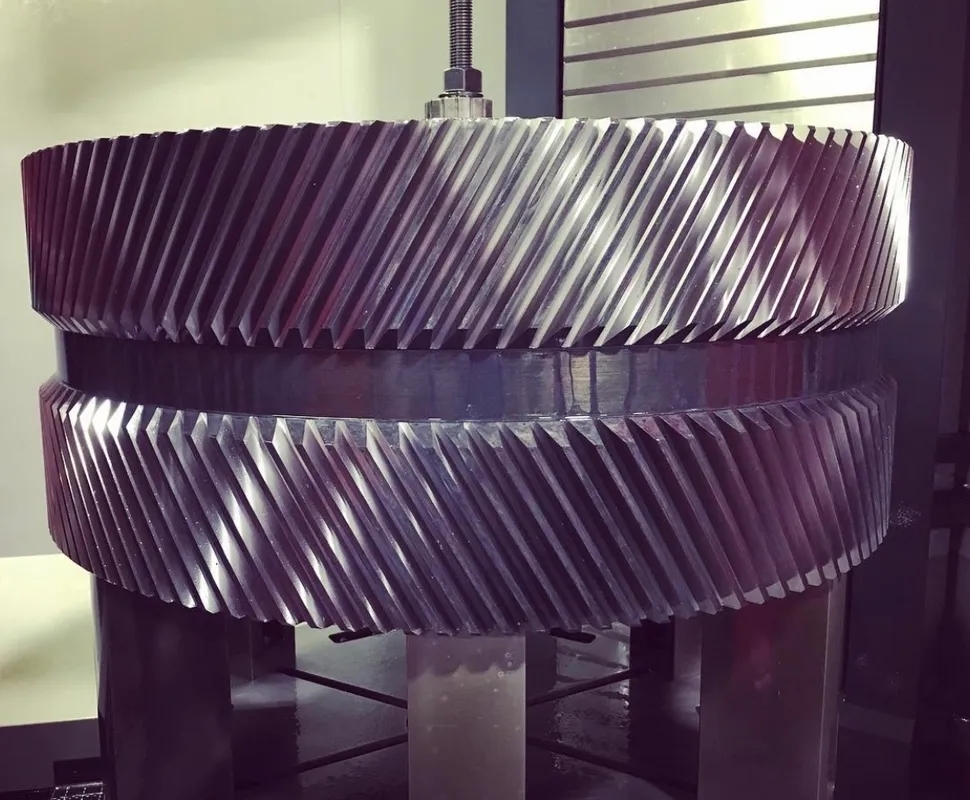

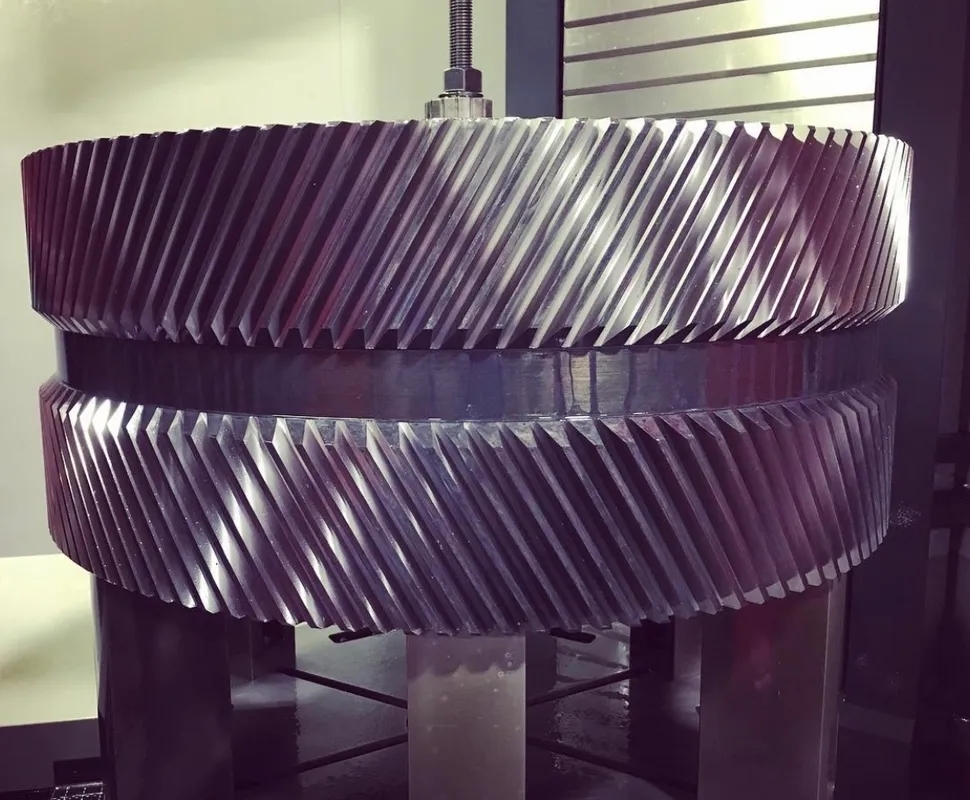

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

Corrosion resistance is a crucial factor in the material selection process for gearbox housing, especially in applications where the gearbox may be exposed to harsh environments or corrosive substances. Materials with high corrosion resistance, such as stainless steel or certain alloys, are preferred to ensure the gearbox housing can withstand prolonged exposure to moisture, chemicals, or other corrosive agents without deteriorating or compromising its structural integrity.

Cost is an important consideration in the decision-making process when choosing a material for gearbox housing. While it is essential to select a material that meets the required performance and durability criteria, the overall cost of the material, manufacturing process, and maintenance should also be taken into account. Balancing performance requirements with cost considerations can help optimize the overall value and efficiency of the gearbox assembly.

Gearbox misalignment can indeed lead to premature wear in machinery. When the gears in a gearbox are not properly aligned, it can cause increased friction, uneven distribution of forces, and excessive vibration. This can result in accelerated wear and tear on the gears, bearings, and other components of the gearbox. Over time, this can lead to decreased efficiency, increased maintenance costs, and ultimately, the need for premature replacement of parts. It is important to regularly check and correct any misalignment issues in gearboxes to prevent these negative consequences and ensure optimal performance and longevity of the machinery.

When it comes to gearbox maintenance in extreme temperatures, there are several key considerations to keep in mind. First and foremost, it is important to regularly check the gearbox for any signs of wear and tear, as extreme temperatures can accelerate the degradation of components. Additionally, using high-quality lubricants that are specifically designed for the temperature range in which the gearbox operates is crucial to ensure optimal performance. Insulating the gearbox to protect it from temperature fluctuations and ensuring proper ventilation to prevent overheating are also important factors to consider. Regularly monitoring the gearbox's temperature and addressing any issues promptly can help prevent costly repairs and downtime in the long run. Overall, proactive maintenance and attention to detail are essential when operating gearboxes in extreme temperatures.

Specialized gearbox maintenance procedures for underground mining applications typically involve regular inspections, lubrication checks, and monitoring of vibration levels to ensure optimal performance and prevent breakdowns. These procedures may include the use of specialized tools and equipment, such as vibration analysis devices, to detect potential issues early on. Additionally, maintenance schedules may be more frequent in underground mining settings due to the harsh operating conditions and heavy loads placed on the gearboxes. Proper training for maintenance personnel is also crucial to ensure that all procedures are carried out correctly and efficiently. Overall, the goal of specialized gearbox maintenance in underground mining applications is to maximize equipment uptime and productivity while minimizing the risk of costly downtime.

Balancing can indeed enhance the performance of a gearbox by optimizing the distribution of weight and reducing vibrations that can lead to wear and tear. By carefully adjusting the mass distribution of the components within the gearbox, engineers can improve its efficiency, durability, and overall functionality. This process involves precision machining, dynamic balancing, and the use of specialized tools and techniques to ensure that all parts work together seamlessly. Additionally, balancing can help minimize noise levels, increase power transmission, and extend the lifespan of the gearbox. Overall, balancing plays a crucial role in enhancing gearbox performance and ensuring smooth operation in various applications.