When selecting a gearbox lubricant additive, key factors to consider include the compatibility of the additive with the base oil, the intended application of the gearbox, the operating conditions such as temperature and load, and the desired performance enhancements. It is essential to choose an additive that will improve the lubricant's ability to reduce friction, prevent wear, and protect against corrosion in order to maximize the gearbox's efficiency and longevity.

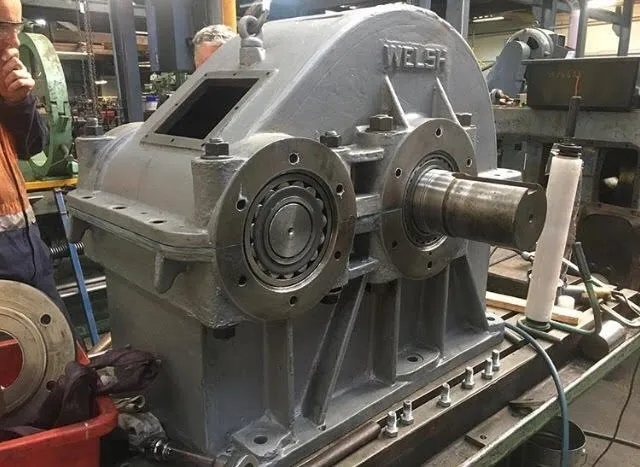

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

Different types of gearbox lubricant additives can have varying effects on performance and longevity. For example, anti-wear additives can help protect gears from damage by forming a protective film on metal surfaces, while extreme pressure additives are crucial for high-stress applications where heavy loads and high temperatures are present. By selecting the right combination of additives, gearbox lubricants can be tailored to meet specific performance requirements and extend the lifespan of the equipment.

Houston Matters goes behind the scenes of the University of Houston-Downtown's new digital concert series.

Posted by on 2024-03-12

Don McLaughlin, who called on the investigation, said acting police chief Mariano Pargas failed as a leader on the day of the mass shooting.

Posted by on 2024-03-12

Rivera last week was charged with capital murder and police escalated their searching efforts for the suspect.

Posted by on 2024-03-12

On Tuesday's show: We discuss a number of environmental stories across the state. And we consider how to deal with seasonal allergies as we near the official start of spring.

Posted by on 2024-03-12

Viscosity index improvers play a crucial role in gearbox lubricant additives by enhancing the oil's viscosity-temperature relationship. These additives help maintain the lubricant's viscosity within a desired range across a wide range of temperatures, ensuring proper lubrication and protection for gears operating in varying conditions. By improving the oil's viscosity index, gearbox lubricants can remain effective in both cold start-ups and high-temperature operations.

Anti-wear additives contribute significantly to protecting gears from damage in gearboxes by forming a protective layer on metal surfaces, reducing friction, and preventing wear. These additives work by creating a barrier between moving parts, minimizing metal-to-metal contact, and extending the lifespan of gears and bearings. By incorporating anti-wear additives into gearbox lubricants, equipment reliability and durability can be greatly enhanced.

Extreme pressure additives in gearbox lubricants are essential for high-stress applications where gears are subjected to heavy loads, shock loads, and high temperatures. These additives contain compounds that react with metal surfaces under extreme pressure conditions, forming a protective layer that prevents welding and seizure of gear teeth. By using lubricants with extreme pressure additives, gearboxes can withstand harsh operating conditions and maintain optimal performance.

Friction modifiers play a crucial role in enhancing the efficiency and smooth operation of gearboxes when added to lubricants. These additives reduce friction between moving parts, improving energy efficiency, reducing heat generation, and minimizing wear on gears. By incorporating friction modifiers into gearbox lubricants, equipment can operate more smoothly, quietly, and with reduced power losses, ultimately extending the lifespan of the gearbox components.

When choosing gearbox lubricant additives for specific operating conditions, considerations should be made based on factors such as temperature, load, speed, and environmental conditions. It is essential to select additives that can withstand the intended operating temperature range, provide adequate protection under heavy loads, and resist oxidation and corrosion in harsh environments. By tailoring the lubricant additives to the specific requirements of the gearbox, optimal performance, longevity, and reliability can be achieved.

Gearbox noise analysis can be a complex process that requires specialized techniques to accurately diagnose and address issues. Some of the key methods used in gearbox noise analysis include vibration analysis, acoustic testing, modal analysis, and frequency spectrum analysis. These techniques allow engineers to identify specific sources of noise within the gearbox, such as gear meshing, bearing defects, or lubrication issues. By using advanced tools such as accelerometers, microphones, and spectrum analyzers, experts can pinpoint the root cause of the noise and develop targeted solutions to reduce or eliminate it. Additionally, computer-aided design (CAD) software can be used to simulate gearbox operation and predict potential noise issues before they occur. Overall, a combination of these specialized techniques is essential for effective gearbox noise analysis and troubleshooting.

Indicators of gearbox shaft misalignment can include abnormal vibrations, increased noise levels, overheating, premature wear on bearings, and decreased efficiency in the transmission system. Other signs may include irregular gear tooth wear, shaft breakage, and coupling misalignment. These issues can lead to further damage to the gearbox components and result in costly repairs if not addressed promptly. Regular monitoring and maintenance of the gearbox shaft alignment are essential to prevent these problems and ensure optimal performance of the machinery.

To assess gearbox efficiency losses, engineers typically utilize a combination of methods such as performance testing, thermography, vibration analysis, and oil analysis. Performance testing involves measuring input and output power to calculate efficiency, while thermography can identify areas of overheating indicating energy loss. Vibration analysis helps detect mechanical issues that may be causing inefficiencies, and oil analysis can reveal contamination or wear particles that could be impacting performance. By combining these techniques, engineers can accurately assess gearbox efficiency losses and identify areas for improvement.

Preventing gearbox oil contamination from water can be achieved through various measures. One effective method is to ensure proper sealing of the gearbox to prevent water ingress. Regular maintenance and inspection of seals, gaskets, and O-rings can help identify any potential leaks that may allow water to enter the gearbox. Additionally, using high-quality gearbox oil with water-resistant properties can help mitigate the risk of contamination. Implementing a regular oil change schedule can also prevent water buildup in the gearbox. Furthermore, storing the gearbox in a dry and controlled environment can help minimize the chances of water contamination. Overall, a combination of preventive measures such as proper sealing, maintenance, oil selection, and storage practices can help safeguard the gearbox from water contamination.

Gearbox maintenance procedures for wind turbine applications typically involve regular inspections, lubrication checks, and vibration analysis to ensure optimal performance and prevent potential failures. Specific tasks may include monitoring oil levels, changing filters, inspecting gear teeth for wear, and tightening bolts to prevent loosening. Additionally, technicians may conduct thermographic inspections to detect overheating components and perform oil analysis to identify any contaminants or signs of degradation. By following these detailed maintenance procedures, wind turbine operators can prolong the lifespan of their gearboxes and minimize downtime due to unexpected malfunctions.

When performing gearbox repair, it is important to follow specific safety precautions to prevent accidents and injuries. Some of these precautions include wearing appropriate personal protective equipment such as gloves, safety glasses, and steel-toed boots. It is also important to work in a well-ventilated area to avoid exposure to harmful fumes or gases. Additionally, using proper tools and equipment, following manufacturer guidelines, and ensuring the gearbox is properly supported during repair are all essential safety measures. Regular maintenance and inspections of gearboxes can help identify potential issues before they become safety hazards. Overall, following these safety precautions can help ensure a successful and safe gearbox repair process.