Various types of surface treatments are utilized for gearbox housing, including anodizing, powder coating, painting, and chemical conversion coating. Each of these treatments offers unique benefits in terms of durability, corrosion resistance, and aesthetics.

The surface treatment applied to gearbox housing plays a crucial role in determining its durability and performance. A high-quality surface treatment can enhance the housing's resistance to corrosion, wear, and impact, ultimately prolonging its lifespan and ensuring optimal functionality under various operating conditions.

Other schools in Texas, including University of Houston, will remain test-optional.

Posted by on 2024-03-12

Seven people have died in officer-involved shootings just this month in the Houston area, including in Galveston, Conroe and Montgomery. Each of the men who died was holding a gun at the time that they were shot, and one was brandishing a knife, according to the Houston Police Department.

Posted by on 2024-03-12

Houston Matters goes behind the scenes of the University of Houston-Downtown's new digital concert series.

Posted by on 2024-03-12

Don McLaughlin, who called on the investigation, said acting police chief Mariano Pargas failed as a leader on the day of the mass shooting.

Posted by on 2024-03-12

Rivera last week was charged with capital murder and police escalated their searching efforts for the suspect.

Posted by on 2024-03-12

The process of applying a protective coating to gearbox housing surfaces typically involves thorough cleaning, surface preparation, and the application of the chosen coating material. This coating acts as a barrier against environmental factors, preventing corrosion and damage to the housing components.

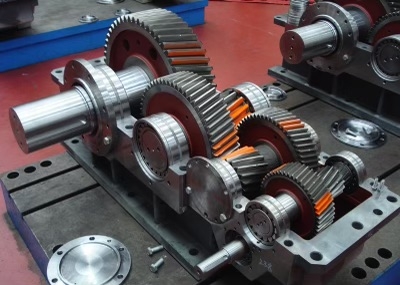

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

Anodizing is a popular surface treatment for gearbox housing due to its excellent corrosion resistance, durability, and aesthetic appeal. The anodized layer formed on the housing surface provides enhanced protection against wear and tear, making it ideal for applications where longevity and performance are critical.

Powder coating is a versatile surface treatment method that offers several advantages for gearbox housing, including superior durability, impact resistance, and a wide range of color options. Compared to traditional painting methods, powder coating provides a more durable and uniform finish, making it a preferred choice for demanding applications.

In high-temperature environments, surface treatments such as ceramic coating or thermal spray coatings are recommended for gearbox housings. These treatments offer enhanced heat resistance, thermal insulation, and protection against thermal cycling, ensuring the housing can withstand extreme temperature conditions without compromising performance.

When selecting the right surface treatment for gearbox housing in corrosive conditions, factors such as the operating environment, exposure to chemicals, and maintenance requirements should be considered. Treatments like chemical conversion coating or specialized corrosion-resistant coatings can provide the necessary protection against corrosion, ensuring the housing remains durable and reliable in harsh environments.

When selecting the appropriate gearbox lubricant viscosity, it is important to consider factors such as operating temperature, load, speed, and gear type. The viscosity of the lubricant should be chosen based on the manufacturer's recommendations and specifications for the specific gearbox in question. It is crucial to ensure that the lubricant provides adequate film thickness to prevent metal-to-metal contact and reduce friction and wear. Additionally, the lubricant should have good thermal stability and resistance to oxidation to maintain its performance over time. By selecting the right viscosity lubricant, the gearbox can operate efficiently and effectively, prolonging its lifespan and reducing the risk of breakdowns or failures.

When it comes to high-speed applications, gearboxes that are best suited are typically those with helical gears, planetary gears, or hypoid gears. These types of gearboxes are designed to handle the increased speeds and torque requirements often found in high-speed applications. Helical gears provide smooth and quiet operation, while planetary gears offer high efficiency and compact design. Hypoid gears are known for their ability to handle heavy loads and high speeds. Additionally, gearboxes with precision machining, high-quality materials, and advanced lubrication systems are also ideal for high-speed applications to ensure optimal performance and durability. Overall, selecting a gearbox with the right gear type and features is crucial for achieving reliable and efficient operation in high-speed applications.

Gearbox overloading can lead to a variety of potential risks, including increased wear and tear on the gears, bearings, and other components within the system. This can result in decreased efficiency, increased heat generation, and ultimately, premature failure of the gearbox. Additionally, overloading can cause excessive vibration, noise, and potential damage to surrounding equipment. In extreme cases, gearbox overloading can lead to catastrophic failure, posing safety risks to personnel and causing costly downtime for repairs and replacements. It is important to monitor and maintain proper load levels to prevent these risks and ensure the longevity and performance of the gearbox.

Gearbox performance can indeed be affected by gearbox mounting issues. When the gearbox is not properly mounted, it can lead to misalignment, increased vibration, and premature wear on the gears and bearings. This can result in decreased efficiency, increased noise levels, and potential damage to other components within the transmission system. It is crucial to ensure that the gearbox is securely and accurately mounted to prevent any negative impacts on its overall performance and longevity. Regular maintenance and inspections of the gearbox mounting system are essential to avoid any potential issues that may arise from improper installation or mounting.

To prevent gearbox water ingress, several measures can be taken to ensure the integrity of the system. One effective method is to regularly inspect and maintain the gearbox seals to ensure they are in good condition and free from any cracks or damage. Additionally, applying a waterproof sealant or coating to vulnerable areas can help create an extra barrier against water penetration. Installing a breather vent with a filter can also help prevent moisture from entering the gearbox while still allowing for pressure equalization. Furthermore, ensuring proper drainage around the gearbox area can help prevent water from pooling and seeping into the system. Regularly monitoring the gearbox for any signs of water ingress, such as milky oil or corrosion, can also help detect any issues early on and prevent further damage.