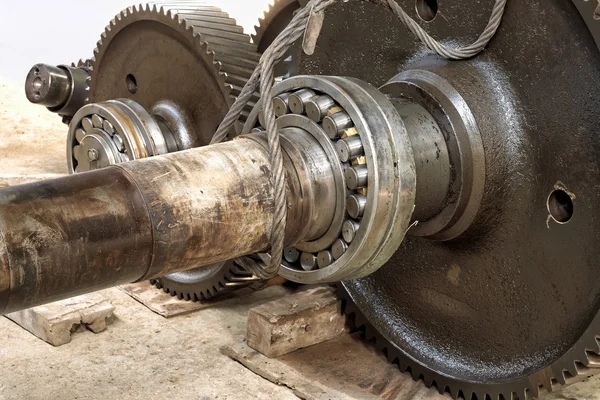

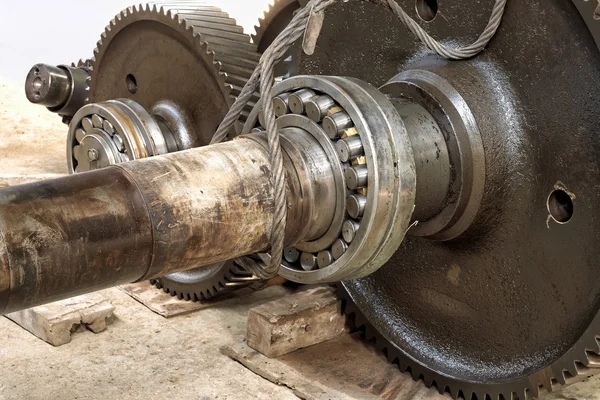

Common signs of wear and tear in industrial gearboxes include abnormal noise during operation, overheating, leakage of oil or grease, vibration, and changes in performance such as reduced efficiency or power output. These signs can indicate issues such as worn gears, bearings, seals, or other components that may require maintenance or repair.

Industrial gearbox repair is a crucial aspect of maintaining efficient operations in manufacturing plants and industrial facilities. Ensuring timely repairs not only minimizes downtime but also extends the lifespan of equipment, ultimately optimizing productivity. To learn more or inquire about industrial gearbox repair services, visit: https://precisiongearrepair.com/gearbox-repair/

Efficient repair services and access to quality replacement parts are essential components of sustaining a smooth-running industrial operation. By addressing gearbox issues promptly and utilizing reliable equipment, businesses can safeguard against costly breakdowns and maintain peak performance levels in their machinery.

Industrial gearboxes should be inspected for maintenance purposes on a regular basis, typically every 6 to 12 months depending on the operating conditions and workload. However, in high-demand environments or where critical operations are involved, more frequent inspections may be necessary to ensure optimal performance and prevent unexpected failures.

The new fiscal year begins in July and the city is anticipating a budgetary gap of about $160 million.

Posted by on 2024-03-08

Rivera last week was charged with capital murder and police escalated their searching efforts for the suspect.

Posted by on 2024-03-12

After Gov. Greg Abbott said there should be consequences for the suspended cases via X, Whitmire suggested the state send money to Houston to help HPD.

Posted by on 2024-03-11

Each month, we turn to the Garden Club of Houston’s Meg Tapp to offer advice for Houston area gardeners.

Posted by on 2024-03-11

The main causes of industrial gearbox failure can vary but often include lack of proper lubrication, overloading, misalignment, contamination, and poor maintenance practices. These factors can lead to accelerated wear and tear, increased friction, and ultimately result in gearbox failure if not addressed in a timely manner.

Industrial gearboxes can be repaired on-site by experienced technicians, depending on the extent of the damage and the availability of spare parts. However, in cases where specialized equipment or expertise is required, the gearbox may need to be sent to a dedicated repair facility for more comprehensive repairs.

Different types of industrial gearbox repair services available in the market include gearbox rebuilding, gear and bearing replacement, shaft alignment, oil and seal replacement, and overall performance testing and adjustments. These services are typically offered by specialized repair shops or maintenance companies with expertise in gearbox repair and maintenance.

Specific safety precautions need to be taken during industrial gearbox repair to ensure the well-being of technicians and prevent accidents. This may include proper lockout/tagout procedures, wearing appropriate personal protective equipment, following manufacturer guidelines, and using specialized tools and equipment to safely disassemble and reassemble the gearbox.

To minimize downtime during industrial gearbox repair and maintenance processes, businesses can implement proactive maintenance schedules, conduct regular inspections, keep spare parts on hand, train staff on proper maintenance procedures, and work with reliable repair service providers. By staying ahead of potential issues and addressing them promptly, businesses can reduce the risk of unexpected failures and keep operations running smoothly.

When determining the appropriate gearbox lubricant volume, it is important to consider factors such as gear type, operating conditions, and manufacturer recommendations. The volume of lubricant needed will vary depending on the size and design of the gearbox, as well as the speed and load at which it operates. It is crucial to consult the gearbox manual or contact the manufacturer to determine the correct lubricant volume for optimal performance and longevity. Additionally, factors such as temperature, viscosity, and oil type should be taken into account when calculating the appropriate volume of lubricant to ensure proper lubrication and protection of the gearbox components. Regular maintenance and monitoring of the lubricant level are also essential to prevent damage and ensure smooth operation of the gearbox.

When addressing gearbox lubrication blockages, it is important to first identify the root cause of the issue. Common reasons for blockages include contamination, inadequate lubrication, or mechanical failures. To resolve the blockage, one can utilize methods such as flushing the system, replacing the lubricant, cleaning filters, or repairing any damaged components. It is crucial to follow manufacturer guidelines and use appropriate tools and equipment to ensure proper maintenance and prevent future blockages. Regular inspections and maintenance routines can help detect and address blockages before they escalate into more severe problems. By addressing gearbox lubrication blockages promptly and effectively, one can ensure optimal performance and longevity of the equipment.

One way to identify gearbox seal leaks is to look for signs of oil or fluid dripping or pooling underneath the vehicle. Other indicators may include a decrease in fluid levels, visible cracks or damage to the seal itself, and a burning smell coming from the gearbox. Additionally, a visual inspection of the gearbox housing and surrounding components may reveal signs of leakage, such as oil stains or residue. It is important to address gearbox seal leaks promptly to prevent further damage to the transmission system and ensure optimal performance of the vehicle.

Filtration systems play a crucial role in gearbox maintenance by removing contaminants such as dirt, debris, and metal particles from the lubricating oil. These systems help prevent wear and tear on gearbox components, improve overall performance, and extend the lifespan of the gearbox. By capturing and filtering out harmful particles, filtration systems ensure that the lubricating oil remains clean and effective in reducing friction and heat within the gearbox. Regular maintenance of filtration systems is essential to ensure optimal gearbox performance and prevent costly repairs or replacements. Proper filtration also helps maintain the viscosity and integrity of the lubricating oil, ensuring smooth operation and efficient power transmission within the gearbox.

The performance of a gearbox can indeed be affected by humidity levels. High levels of humidity can lead to increased moisture within the gearbox, potentially causing corrosion, rust, and lubrication breakdown. This can result in decreased efficiency, increased friction, and ultimately, a decrease in overall performance. It is important to monitor and control humidity levels in the environment where the gearbox is located to ensure optimal functioning and longevity. Additionally, proper maintenance and regular inspections can help mitigate the negative effects of humidity on gearbox performance.

Recommended maintenance procedures for gearbox housings include regular inspections for signs of wear, corrosion, or leaks. It is important to check the housing for any cracks, dents, or other damage that could compromise its integrity. Additionally, lubrication of the gearbox housing is essential to ensure smooth operation and prevent overheating. Cleaning the housing regularly to remove dirt, debris, and contaminants is also recommended to prevent premature wear and tear. Proper storage of the gearbox housing when not in use can help prolong its lifespan and prevent damage. Overall, following a comprehensive maintenance schedule and addressing any issues promptly can help ensure the longevity and efficiency of gearbox housings.