Gear tooth root stress analysis is crucial in determining the strength and durability of a gearbox gear by evaluating the stress levels at the root of the gear teeth. This analysis helps engineers understand how much load the gear can withstand before failure, allowing them to design gears that can operate efficiently under various conditions. By calculating the stress distribution at the root of the gear teeth, engineers can ensure that the gear is robust enough to handle the forces and torque it will experience during operation.

Several factors influence the stress levels at the root of gear teeth in a gearbox, including the material properties of the gear, the design of the gear tooth profile, the operating conditions, and the manufacturing process. The geometry of the gear teeth, such as the tooth profile, pressure angle, and tooth thickness, can also impact the stress distribution. Additionally, the meshing conditions, lubrication, and alignment of the gears can affect the stress levels at the root of the gear teeth.

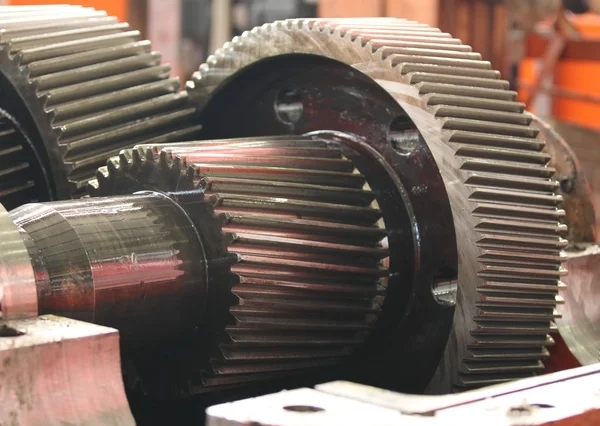

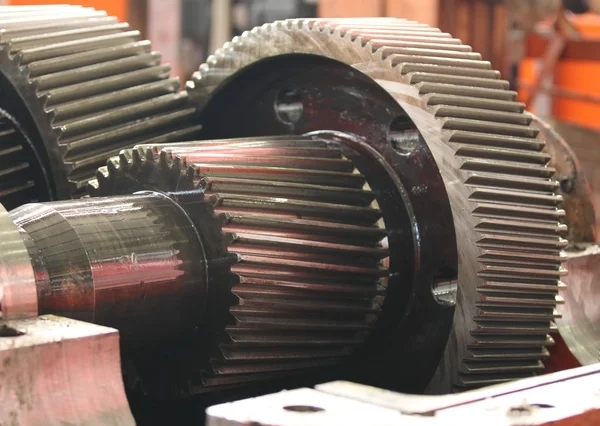

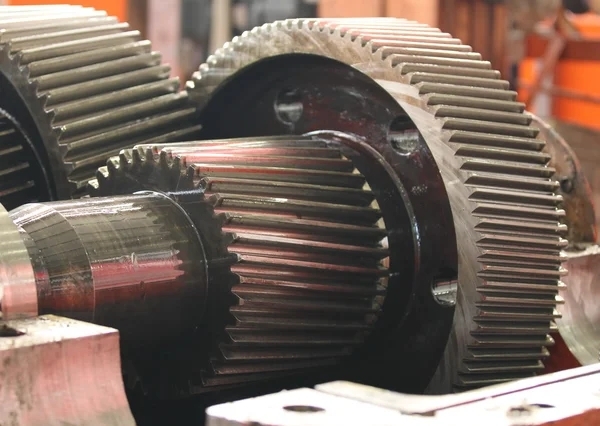

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

On Monday's show: We talk with NPR's White House Correspondent about the Republican National Convention, then we answer your questions about sleep and gardening--separately, of course.

Posted by on 2024-03-11

Houston ISD is again embroiled in internal strife and public controversy. On Friday, the district released performance ratings to principals. After the Houston Chronicle published details about the ratings, the administration suggested the possibility of legal action against the news outlet and launched an investigation to find the source of the leak.

Posted by on 2024-03-11

Episode: 1132 In which balloons deliver the mail during the Siege of Paris. Today, the very first airmail service is used to break a siege.

Posted by on 2024-03-11

Episode: 1131 John Hunter: idiosyncratic medical pioneer. Today, the history of medicine provides a strange hero.

Posted by on 2024-03-10

Episode: 1129 In which Alphonse Penaud invents the model airplane. Today, a very young man teaches us to fly, after all.

Posted by on 2024-03-09

Yes, gear tooth root stress analysis can be used to predict potential failures in a gearbox gear. By analyzing the stress levels at the root of the gear teeth, engineers can identify areas of high stress concentration that may lead to fatigue failure. This information allows them to make design modifications or select appropriate materials to improve the strength and durability of the gear, ultimately reducing the risk of unexpected failures during operation.

The gear tooth root stress analysis may vary for different types of gears, such as spur gears, helical gears, or bevel gears, due to their unique tooth profiles and meshing characteristics. For example, helical gears have a more gradual engagement compared to spur gears, which can affect the stress distribution at the root of the gear teeth. Bevel gears, on the other hand, have a different tooth geometry that can influence the stress levels in a gearbox. Engineers must consider these differences when conducting stress analysis for different types of gears.

Material selection plays a significant role in the stress analysis of gear tooth roots in a gearbox. The material properties, such as strength, hardness, and fatigue resistance, directly impact the stress levels that the gear can withstand. By choosing the right material for the gear, engineers can ensure that it can handle the required loads and operating conditions without experiencing premature failure. Additionally, the material selection can influence the manufacturing process and heat treatment, which can further affect the stress distribution at the root of the gear teeth.

There are specific design considerations that can help reduce stress concentrations at the root of gear teeth in a gearbox. For example, optimizing the tooth profile, modifying the tooth thickness, or adding fillets at the root of the gear teeth can help distribute the stress more evenly and reduce the risk of fatigue failure. Improving the surface finish, ensuring proper alignment, and optimizing the lubrication system are also important factors to consider in reducing stress concentrations and improving the overall performance of the gearbox gear.

Finite element analysis (FEA) can be used to enhance the accuracy of gear tooth root stress analysis in gearboxes by providing a detailed simulation of the stress distribution within the gear teeth. FEA allows engineers to model the complex geometry of the gear teeth, apply realistic loading conditions, and analyze the stress levels at different points along the tooth profile. By using FEA, engineers can identify areas of high stress concentration, optimize the design parameters, and validate the performance of the gearbox gear before manufacturing. This advanced analysis tool helps ensure the reliability and durability of the gear under various operating conditions.

The efficiency of a gearbox can indeed be influenced by the design of the gearbox housing. Factors such as the material used, the shape and size of the housing, the presence of cooling mechanisms, and the overall construction can all impact the performance of the gearbox. A well-designed gearbox housing can help to reduce friction, improve heat dissipation, enhance lubrication distribution, and minimize vibration, all of which can contribute to higher efficiency and smoother operation of the gearbox. Additionally, features such as proper sealing and alignment within the housing can also play a crucial role in maintaining optimal efficiency levels. Therefore, gearbox manufacturers often pay close attention to the housing design to ensure that it complements the internal components and contributes to overall performance.

To prevent gearbox contamination from external debris, several measures can be taken. One effective method is to install high-quality seals and gaskets to create a barrier between the gearbox and the surrounding environment. Regularly inspecting and maintaining these seals can help ensure they are functioning properly. Additionally, implementing proper ventilation systems can help prevent the buildup of dust and dirt around the gearbox. Keeping the surrounding area clean and free of debris can also help reduce the risk of contamination. Using filters and screens on any openings or vents can further prevent debris from entering the gearbox. Overall, a combination of these measures can help protect the gearbox from external contamination and ensure optimal performance.

When addressing gearbox gear tooth pitting, it is important to first identify the root cause of the issue, which can include factors such as improper lubrication, misalignment, overloading, or material defects. Once the cause is determined, the gears may need to be repaired or replaced to prevent further damage and ensure optimal performance. Common methods for addressing gear tooth pitting include grinding, shot peening, or applying surface treatments such as nitriding or carburizing to improve the hardness and wear resistance of the gears. Regular maintenance and monitoring of the gearbox can also help prevent future instances of gear tooth pitting.

When selecting the appropriate gearbox lubricant viscosity, it is important to consider factors such as operating temperature, load, speed, and gear type. The viscosity of the lubricant should be chosen based on the manufacturer's recommendations and specifications for the specific gearbox in question. It is crucial to ensure that the lubricant provides adequate film thickness to prevent metal-to-metal contact and reduce friction and wear. Additionally, the lubricant should have good thermal stability and resistance to oxidation to maintain its performance over time. By selecting the right viscosity lubricant, the gearbox can operate efficiently and effectively, prolonging its lifespan and reducing the risk of breakdowns or failures.