Optimizing the gear tooth profile in a gearbox can significantly improve efficiency by reducing friction and wear between the gears. By carefully designing the shape and size of the gear teeth, engineers can minimize energy losses due to sliding and rolling contact. This optimization can lead to smoother operation, lower heat generation, and ultimately higher overall efficiency of the gearbox.

Lubrication plays a crucial role in maximizing gearbox efficiency by reducing friction and wear between moving parts. Proper lubrication helps to create a protective film between the gear teeth, bearings, and other components, reducing metal-to-metal contact and minimizing energy losses. Using high-quality lubricants and ensuring proper maintenance can significantly improve the efficiency and longevity of a gearbox.

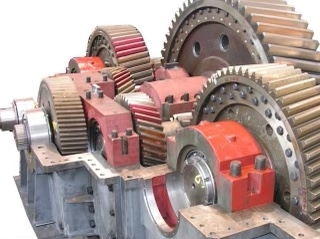

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

Episode: 2998 Test Tube Evolution. Today, evolution in a test tube.

Posted by on 2024-03-13

It's allergy season in Houston, and many are feeling its impact. But allergist Dr. Dat Tran said the pollen count is low compared to 2023.

Posted by on 2024-03-12

“I was prepared to roll out some improvements and reforms, but was unsatisfied with the product that I received from Public Works yesterday,” said Mayor Whitmire during Tuesday’s public session meeting. “So I sent them back to the drawing board.”

Posted by on 2024-03-11

On Monday's show: We talk with NPR's White House Correspondent about the Republican National Convention, then we answer your questions about sleep and gardening--separately, of course.

Posted by on 2024-03-11

The Livestock Show and Rodeo will continue through Sunday, March 17.

Posted by on 2024-03-11

The selection of materials for gearbox components can have a significant impact on overall efficiency. Choosing materials with high strength, durability, and low friction coefficients can help reduce energy losses due to friction and wear. Additionally, selecting materials with good thermal conductivity can help dissipate heat more effectively, further improving efficiency and preventing overheating in the gearbox.

There are several common methods used to reduce friction losses in gearboxes, including optimizing gear tooth profiles, using high-quality lubricants, improving surface finishes, and implementing proper alignment and assembly techniques. Additionally, incorporating rolling element bearings, such as ball or roller bearings, can help reduce friction and improve efficiency by minimizing sliding contact between components.

The design of bearings in a gearbox can have a significant impact on efficiency. By choosing the right type and size of bearings, engineers can reduce friction losses and improve the overall performance of the gearbox. Properly designed bearings can help distribute loads evenly, reduce vibration, and ensure smooth operation, all of which contribute to optimizing gearbox efficiency.

Using helical gears in a gearbox can offer several benefits in terms of efficiency. Helical gears have angled teeth that gradually engage, resulting in smoother and quieter operation compared to spur gears. This reduced noise and vibration can help minimize energy losses and improve overall efficiency. Additionally, the increased contact area of helical gears can distribute loads more evenly, further enhancing efficiency.

Proper alignment of gears is essential for optimizing gearbox efficiency. Misalignment can lead to increased friction, wear, and energy losses due to uneven distribution of loads and improper contact between gear teeth. By ensuring precise alignment of gears during assembly and maintenance, engineers can minimize these issues and improve the overall efficiency and performance of the gearbox.

When it comes to gearbox maintenance in extreme temperatures, there are several key considerations to keep in mind. First and foremost, it is important to regularly check the gearbox for any signs of wear and tear, as extreme temperatures can accelerate the degradation of components. Additionally, using high-quality lubricants that are specifically designed for the temperature range in which the gearbox operates is crucial to ensure optimal performance. Insulating the gearbox to protect it from temperature fluctuations and ensuring proper ventilation to prevent overheating are also important factors to consider. Regularly monitoring the gearbox's temperature and addressing any issues promptly can help prevent costly repairs and downtime in the long run. Overall, proactive maintenance and attention to detail are essential when operating gearboxes in extreme temperatures.

Specialized gearbox maintenance procedures for underground mining applications typically involve regular inspections, lubrication checks, and monitoring of vibration levels to ensure optimal performance and prevent breakdowns. These procedures may include the use of specialized tools and equipment, such as vibration analysis devices, to detect potential issues early on. Additionally, maintenance schedules may be more frequent in underground mining settings due to the harsh operating conditions and heavy loads placed on the gearboxes. Proper training for maintenance personnel is also crucial to ensure that all procedures are carried out correctly and efficiently. Overall, the goal of specialized gearbox maintenance in underground mining applications is to maximize equipment uptime and productivity while minimizing the risk of costly downtime.

Balancing can indeed enhance the performance of a gearbox by optimizing the distribution of weight and reducing vibrations that can lead to wear and tear. By carefully adjusting the mass distribution of the components within the gearbox, engineers can improve its efficiency, durability, and overall functionality. This process involves precision machining, dynamic balancing, and the use of specialized tools and techniques to ensure that all parts work together seamlessly. Additionally, balancing can help minimize noise levels, increase power transmission, and extend the lifespan of the gearbox. Overall, balancing plays a crucial role in enhancing gearbox performance and ensuring smooth operation in various applications.

When it comes to gearbox maintenance, there are several specialized tools that can be used to ensure optimal performance and longevity. Some of these tools include gear pullers, bearing pullers, torque wrenches, dial indicators, and gear shimming tools. Gear pullers are used to remove gears from shafts, while bearing pullers are used to remove bearings from gearboxes. Torque wrenches are essential for tightening bolts to the correct specifications, while dial indicators are used to measure gear backlash and runout. Gear shimming tools are used to adjust the spacing between gears for proper meshing. These specialized tools are designed to make gearbox maintenance easier and more efficient, ultimately helping to prevent costly repairs and downtime.

The efficiency of a gearbox can indeed be influenced by the material used for the gearbox housing. The choice of material can impact factors such as heat dissipation, weight, durability, and overall performance. For example, using lightweight materials like aluminum or magnesium can improve the efficiency by reducing the overall weight of the gearbox, leading to less energy loss during operation. Additionally, materials with good thermal conductivity can help dissipate heat more effectively, preventing overheating and improving overall efficiency. On the other hand, using materials with poor durability or high friction coefficients can negatively affect the gearbox's efficiency by increasing wear and energy loss. Therefore, selecting the appropriate gearbox housing material is crucial in optimizing the efficiency and performance of the gearbox.