A gearbox emergency repair kit typically includes common components such as gaskets, seals, bearings, gears, shafts, and other essential parts that may need to be replaced in case of a gearbox failure. These kits are designed to provide a quick and efficient solution to address issues that may arise unexpectedly, allowing for a timely repair to minimize downtime.

Gearbox emergency repair kits play a crucial role in preventing costly downtime for industrial machinery by providing a quick and effective solution to address gearbox failures. By having these kits readily available, maintenance teams can swiftly respond to issues, make necessary repairs on the spot, and get the machinery back up and running in a timely manner. This proactive approach helps to minimize production interruptions and avoid potential financial losses associated with extended downtime.

After Gov. Greg Abbott said there should be consequences for the suspended cases via X, Whitmire suggested the state send money to Houston to help HPD.

Posted by on 2024-03-11

“I was prepared to roll out some improvements and reforms, but was unsatisfied with the product that I received from Public Works yesterday,” said Mayor Whitmire during Tuesday’s public session meeting. “So I sent them back to the drawing board.”

Posted by on 2024-03-11

Houston officials and community members are touting the success of the barricades they say have driven away prostitutes and those actively seeking them.

Posted by on 2024-03-11

The 54-year-old Anderson, known for feature-length films such as "Rushmore," "The Royal Tenenbaums," "Fantastic Mr. Fox" and "Asteroid City," won in the Best Live Action Short Film category for "The Wonderful Story of Henry Sugar." He had previously been nominated for seven Academy Awards.

Posted by on 2024-03-11

Gearbox emergency repair kits are typically designed to be versatile and adaptable to various types of gearboxes. While there may be specific kits tailored to certain models or brands, many kits are designed to be compatible with a wide range of gearboxes commonly used in industrial settings. It is important to ensure that the kit selected matches the specifications of the gearbox in question to ensure a successful repair.

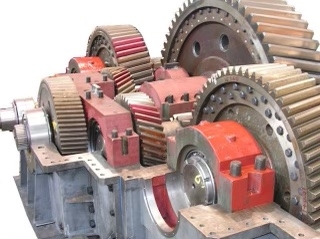

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

Gearbox emergency repair kits can be used for both manual and automatic transmissions, as they contain components and tools that are essential for addressing issues in a gearbox regardless of its type. Whether it is a manual gearbox in a traditional vehicle or an automatic transmission in a modern industrial machine, these kits are equipped to handle a variety of gearbox repair needs efficiently.

Typical tools and materials found in a gearbox emergency repair kit include wrenches, screwdrivers, pliers, lubricants, cleaning supplies, replacement parts, and other essential items needed to perform emergency repairs on a gearbox. These kits are carefully curated to ensure that maintenance teams have everything they need to address common gearbox issues quickly and effectively.

Gearbox emergency repair kits can be deployed rapidly in case of a gearbox failure, as they are designed to be easily accessible and portable. Maintenance teams can quickly grab the kit, assess the issue, and begin the repair process without delay. This swift response time is crucial in minimizing downtime and ensuring that the machinery is back in operation as soon as possible.

There are different sizes and variations of gearbox emergency repair kits available to cater to different types of machinery and gearbox models. Some kits may be more specialized for specific industries or applications, while others may be more general-purpose and suitable for a wide range of gearboxes. It is important to select the appropriate kit based on the specific needs and requirements of the machinery in question to ensure a successful repair.

Seals play a crucial role in gearbox protection by preventing the leakage of lubricants and contaminants, such as dirt, water, and debris, into the gearbox system. These seals create a barrier between the internal components of the gearbox and the external environment, ensuring optimal performance and longevity of the gearbox. By maintaining a tight seal, seals help to reduce friction, wear, and corrosion within the gearbox, ultimately extending the lifespan of the equipment. Additionally, seals help to maintain proper lubrication levels within the gearbox, ensuring smooth operation and preventing overheating. Overall, seals are essential components in gearbox protection, safeguarding the system against potential damage and ensuring efficient operation.

Specialized gearbox maintenance procedures for oil and gas applications typically involve regular inspections, lubrication checks, and vibration analysis to ensure optimal performance and prevent costly downtime. These procedures may include monitoring oil levels, changing filters, inspecting seals, and checking for any signs of wear or damage. Additionally, specialized tools and equipment may be used to accurately measure gear tooth wear, alignment, and backlash. It is important to follow manufacturer recommendations and industry standards to maintain the efficiency and reliability of gearboxes in oil and gas applications. Regular maintenance can help extend the lifespan of equipment and minimize the risk of unexpected failures in critical operations.

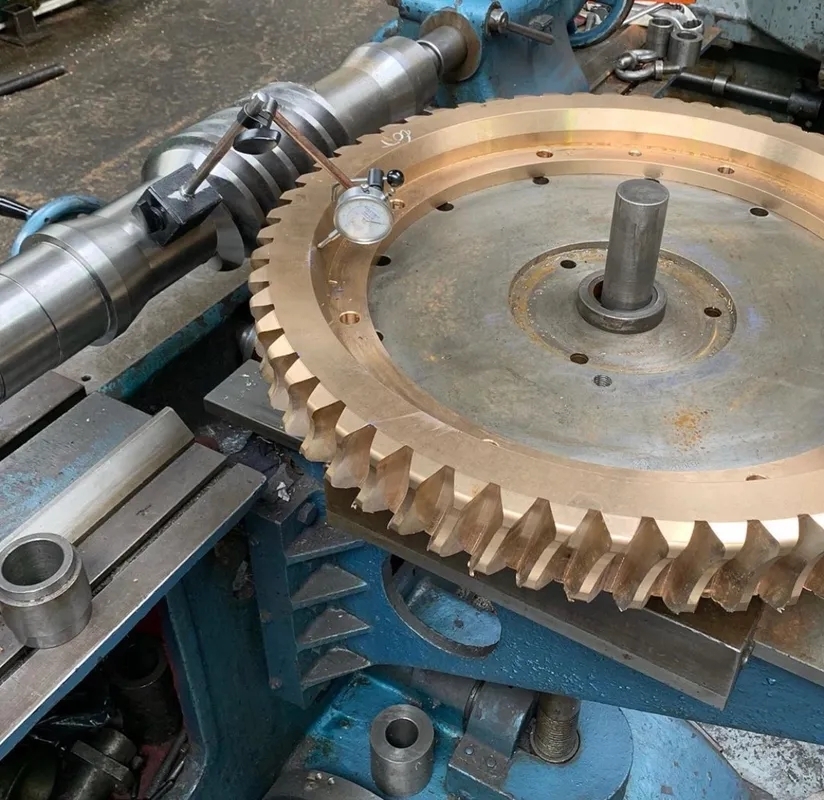

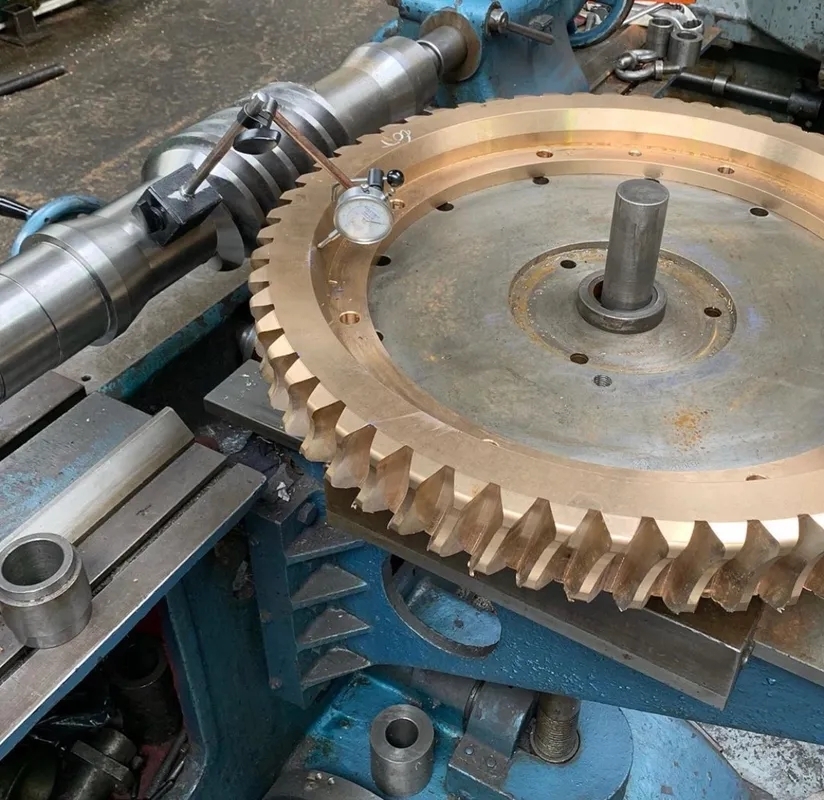

Gearbox shaft alignment is typically achieved using precision alignment tools such as dial indicators, laser alignment systems, and alignment jacks. These tools allow technicians to accurately measure and adjust the position of the gearbox shafts to ensure they are perfectly aligned. Additionally, shims, spacers, and adjustable mounts may be used to fine-tune the alignment of the shafts. Proper alignment is crucial for reducing wear and tear on the gearbox components, improving efficiency, and preventing premature failure. Regular maintenance and monitoring of gearbox shaft alignment are essential to ensure optimal performance and longevity of the equipment.

Common signs of gearbox bearing failure include unusual noises such as grinding, whining, or rumbling coming from the transmission, difficulty shifting gears, vibrations felt while driving, leaking transmission fluid, and a burning smell. Other indicators may include a decrease in overall performance, increased fuel consumption, and visible damage to the gearbox components. It is important to address these symptoms promptly to prevent further damage to the transmission system. Regular maintenance and inspections can help identify bearing issues early on and prevent costly repairs down the line.

When troubleshooting gearbox filter blockages, it is important to first identify the root cause of the issue. Common reasons for blockages include debris buildup, oil contamination, or a faulty filter. To address this, one can start by inspecting the filter for any visible signs of blockage or damage. Next, the oil level and quality should be checked to ensure proper lubrication and filtration. Using diagnostic tools such as pressure gauges can help determine if there is a restriction in the filter. If a blockage is confirmed, the filter may need to be cleaned or replaced. Additionally, checking for any leaks or other mechanical issues that may be contributing to the blockage is recommended. Regular maintenance and monitoring of the gearbox filter can help prevent future blockages and ensure optimal performance of the system.