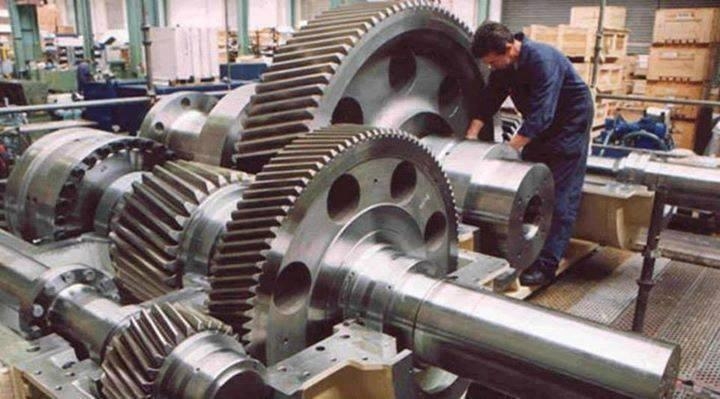

Gear mesh analysis tools play a crucial role in determining the contact pattern and alignment of gears by analyzing the meshing behavior of gear teeth. These tools utilize advanced algorithms to simulate the interaction between gear teeth, allowing engineers to visualize the contact pattern and identify any potential issues such as misalignment or uneven wear. By analyzing the contact pattern, engineers can make adjustments to optimize the gear meshing process and ensure smooth operation of the gear system.

Key parameters that gear mesh analysis tools can measure to ensure optimal gear performance include tooth contact ratio, backlash, tooth root stress, and contact pressure distribution. By analyzing these parameters, engineers can assess the efficiency and durability of the gear system, as well as identify any potential areas of improvement. By monitoring these key parameters, engineers can make informed decisions to enhance gear performance and prevent premature wear or failure.

Seven people have died in officer-involved shootings just this month in the Houston area, including in Galveston, Conroe and Montgomery. Each of the men who died was holding a gun at the time that they were shot, and one was brandishing a knife, according to the Houston Police Department.

Posted by on 2024-03-12

Houston Matters goes behind the scenes of the University of Houston-Downtown's new digital concert series.

Posted by on 2024-03-12

Don McLaughlin, who called on the investigation, said acting police chief Mariano Pargas failed as a leader on the day of the mass shooting.

Posted by on 2024-03-12

Rivera last week was charged with capital murder and police escalated their searching efforts for the suspect.

Posted by on 2024-03-12

Gear mesh analysis tools assist in identifying potential issues such as misalignment, tooth wear, or damage in gear systems by analyzing the meshing behavior of gear teeth. These tools can detect abnormalities in the contact pattern, such as uneven wear or excessive backlash, which may indicate underlying issues with the gear system. By identifying these potential issues early on, engineers can take corrective actions to prevent further damage and ensure the longevity of the gear system.

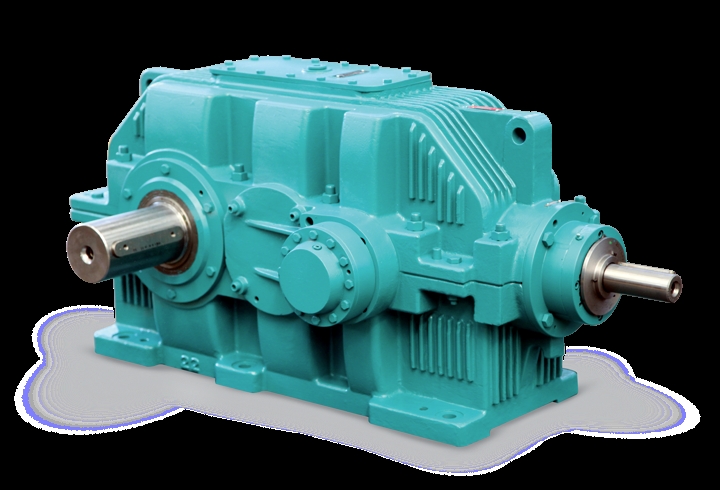

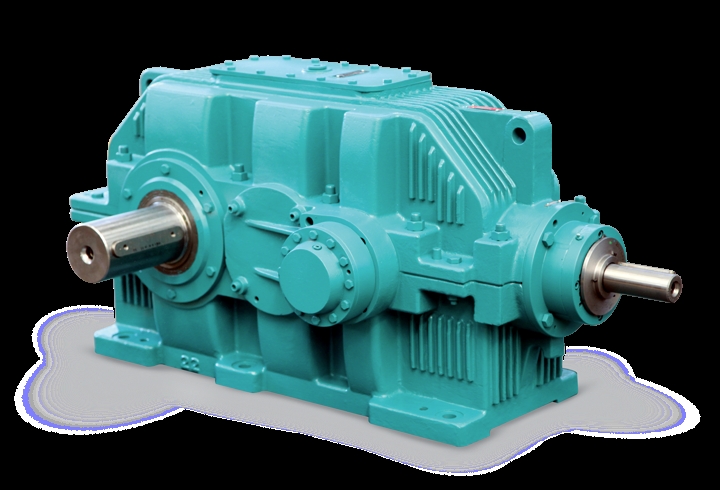

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

Gear mesh analysis tools can provide insights into the efficiency and noise levels of gear systems by analyzing parameters such as meshing efficiency, vibration levels, and noise emissions. By monitoring these factors, engineers can optimize the gear design to reduce noise levels and improve overall system efficiency. By using gear mesh analysis tools, engineers can fine-tune the gear system to achieve optimal performance and minimize noise generation.

There are different types of gear mesh analysis tools available in the market, including software programs, simulation tools, and specialized equipment for gear testing. These tools vary in terms of features and capabilities, with some offering advanced simulation capabilities for complex gear systems, while others focus on specific parameters such as contact pattern analysis or noise prediction. Engineers can choose the appropriate gear mesh analysis tool based on their specific needs and the complexity of the gear system.

Gear mesh analysis tools can be used to optimize gear design and improve overall system performance by analyzing key parameters such as tooth contact ratio, backlash, and contact pressure distribution. By simulating the meshing behavior of gear teeth, engineers can identify areas for improvement and make adjustments to enhance gear performance. By using gear mesh analysis tools, engineers can fine-tune the gear design to achieve optimal efficiency, durability, and noise levels.

In the industry, there are specific software programs and simulation tools commonly used for gear mesh analysis, such as KISSsoft, MASTA, and Romax Technology. These tools offer advanced features for analyzing gear meshing behavior, optimizing gear design, and predicting performance under different operating conditions. Engineers rely on these software programs to simulate gear systems, identify potential issues, and make informed decisions to improve gear performance. By using these specialized tools, engineers can ensure the reliability and efficiency of gear systems in various applications.

In marine applications, specialized gearbox maintenance procedures are essential to ensure optimal performance and longevity of the equipment. These procedures typically involve regular inspections, lubrication checks, and alignment adjustments to prevent wear and tear caused by harsh marine environments. Specific tasks may include checking oil levels, monitoring for water contamination, inspecting seals and gaskets, and replacing worn components as needed. Additionally, marine gearbox maintenance may also involve monitoring vibration levels, conducting oil analysis, and following manufacturer recommendations for service intervals. By following these specialized procedures, marine operators can minimize downtime, reduce the risk of costly repairs, and prolong the lifespan of their gearboxes.

To assess gearbox wear and tear, one can start by inspecting the gears, bearings, shafts, and seals for any signs of damage such as pitting, scoring, or corrosion. It is also important to check for any abnormal noises, vibrations, or leaks coming from the gearbox. Additionally, measuring the backlash, runout, and gear tooth wear can provide valuable information about the condition of the gearbox. Performing oil analysis can help determine if there are any metal particles or contaminants present in the lubricant, indicating potential wear. Regular maintenance and monitoring of these factors can help prevent further damage and ensure the gearbox operates efficiently.

Gearbox temperature sensors play a crucial role in maintenance by monitoring the temperature of the gearbox to ensure optimal performance and prevent overheating. These sensors provide real-time data on the temperature of the gearbox, allowing maintenance technicians to identify any potential issues before they escalate. By detecting abnormal temperature fluctuations, these sensors help prevent damage to the gearbox components and extend the lifespan of the equipment. Additionally, gearbox temperature sensors can trigger alerts or shut down the system automatically if the temperature exceeds safe levels, preventing costly repairs and downtime. Regular monitoring and analysis of the data from these sensors are essential for proactive maintenance and ensuring the reliability of the gearbox.

One way to identify gearbox oil leaks is to look for visible signs of oil dripping or pooling underneath the vehicle. Other indicators may include a decrease in oil levels, a burning smell coming from the engine, or unusual noises while driving. Inspecting the gearbox for cracks, loose fittings, or damaged seals can also help pinpoint the source of the leak. Additionally, checking for oil residue on the transmission housing or surrounding components can provide clues as to where the leak is originating from. Regular maintenance and inspections can help prevent gearbox oil leaks and ensure optimal performance of the vehicle.