In gearbox design, the involute profile of gear teeth can be corrected by adjusting the tooth geometry to ensure proper meshing and smooth operation. This correction is crucial to prevent premature wear and ensure efficient power transmission within the system. By carefully analyzing the tooth profile and making necessary adjustments, engineers can optimize the performance and longevity of the gears in the gearbox.

Common methods used to adjust the tooth profile of gears for optimal performance include tooth profile modification, tooth crowning, and tooth flank correction. These techniques help to improve the contact pattern between the gear teeth, reduce noise and vibration, and enhance the overall efficiency of the gearbox. By fine-tuning the tooth profile, engineers can achieve better load distribution and minimize the risk of tooth failure under operating conditions.

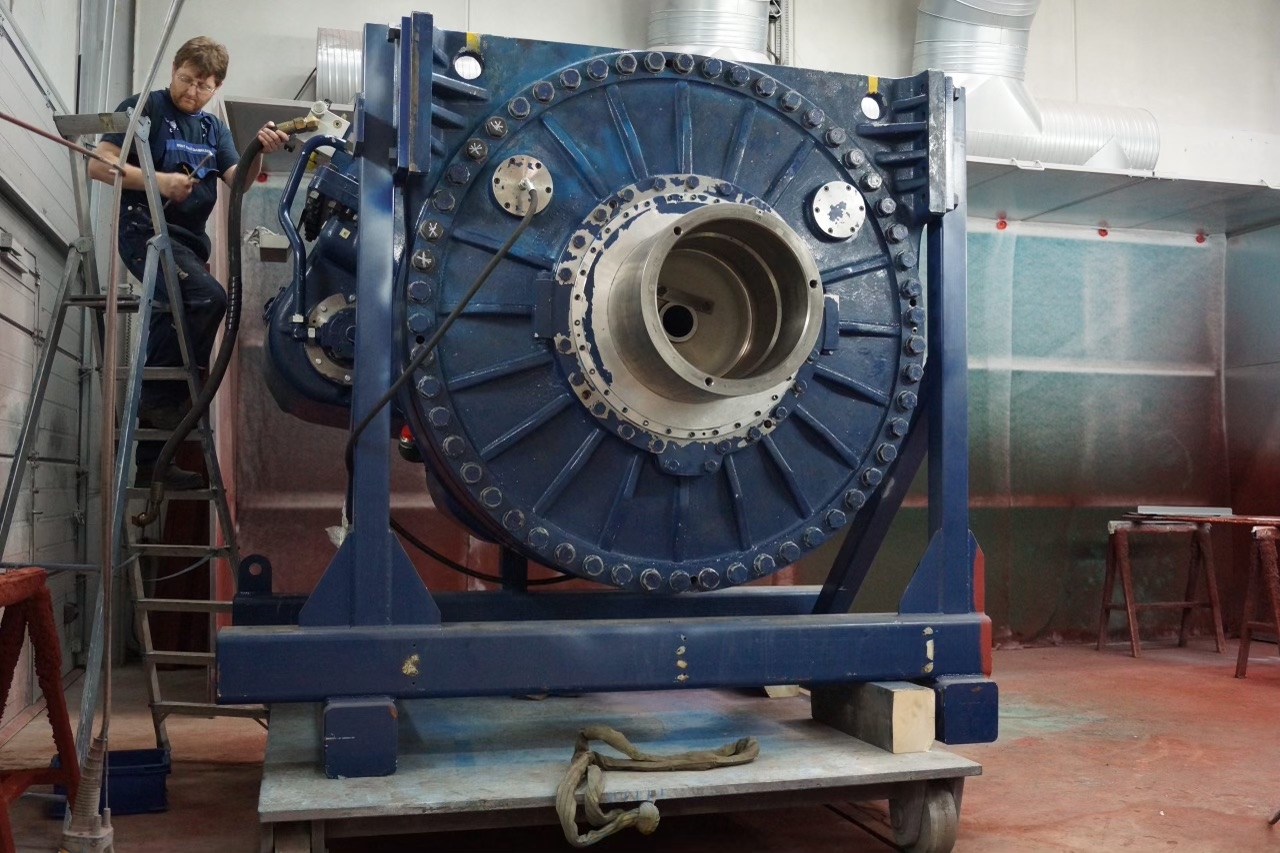

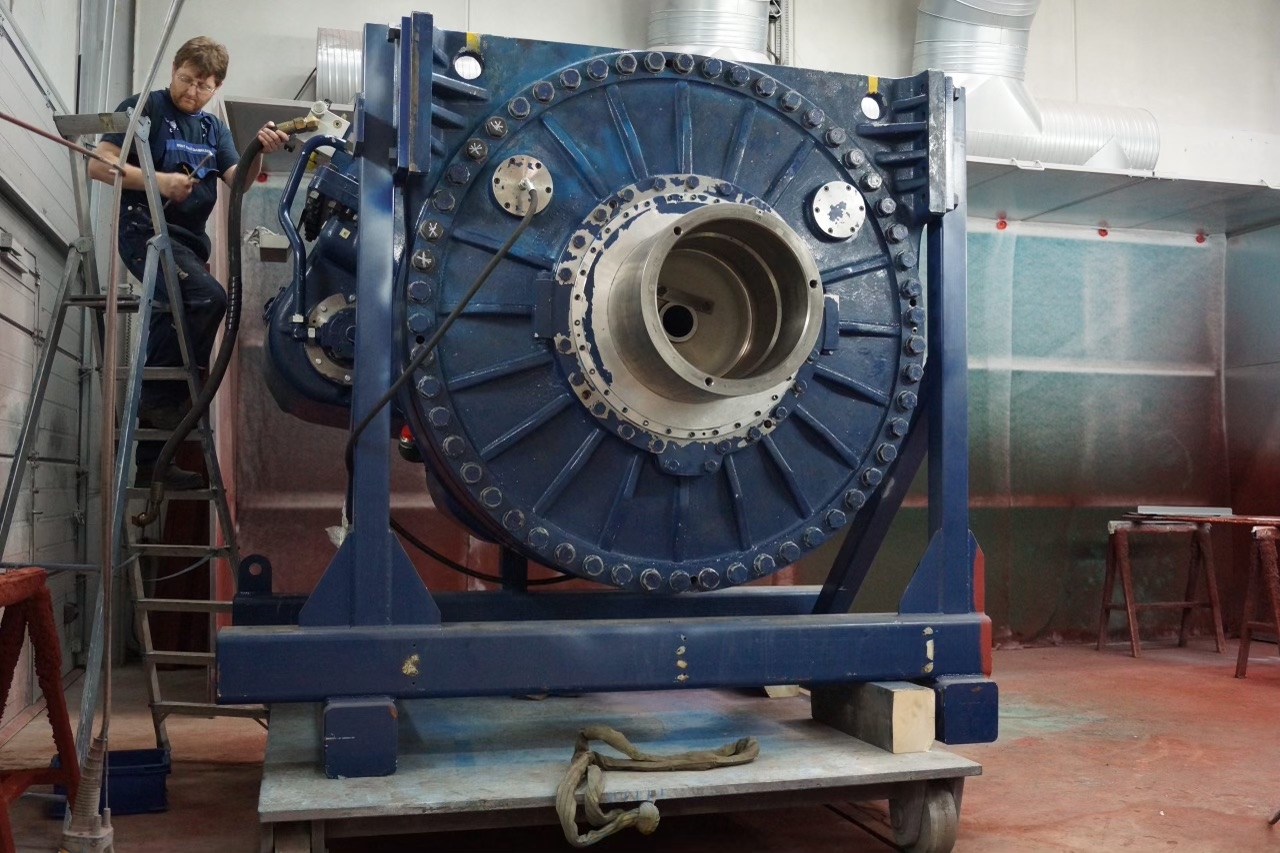

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

The Livestock Show and Rodeo will continue through Sunday, March 17.

Posted by on 2024-03-11

The blooming cycle for Texas' state flower is 2-3 weeks ahead of schedule because of earlier-than-usual warm weather, according to Texas A&M horticulturalist Michael Arnold. Bluebonnets already can be seen in places such as the Houston Botanic Garden.

Posted by on 2024-03-11

After Gov. Greg Abbott said there should be consequences for the suspended cases via X, Whitmire suggested the state send money to Houston to help HPD.

Posted by on 2024-03-11

“I was prepared to roll out some improvements and reforms, but was unsatisfied with the product that I received from Public Works yesterday,” said Mayor Whitmire during Tuesday’s public session meeting. “So I sent them back to the drawing board.”

Posted by on 2024-03-11

Yes, the tooth profile of gears can be modified to reduce noise and vibration in gearboxes. By optimizing the tooth geometry and surface finish, engineers can minimize the impact of meshing forces and improve the overall smoothness of operation. This reduction in noise and vibration not only enhances the user experience but also prolongs the lifespan of the gearbox components by reducing wear and fatigue.

Tooth profile correction plays a crucial role in improving the efficiency of gear systems by ensuring proper alignment and load distribution between the gear teeth. When the tooth profile is accurately designed and corrected, the gears can transmit power more effectively, resulting in higher efficiency and reduced energy losses. By addressing tooth profile issues, engineers can optimize the performance of the gearbox and maximize its overall efficiency.

There are specific software tools available for analyzing and correcting gear tooth profiles, such as gear design software and simulation programs. These tools allow engineers to model the gear geometry, simulate the meshing behavior, and optimize the tooth profile for optimal performance. By utilizing these software tools, engineers can efficiently design and correct gear tooth profiles to meet the desired specifications and performance requirements.

Manufacturing processes have a significant impact on the accuracy of gear tooth profiles and the need for correction. Factors such as machining tolerances, material properties, and heat treatment can affect the final shape and quality of the gear teeth. To ensure precise tooth profiles, manufacturers must carefully control the production processes and implement quality assurance measures to minimize deviations and inaccuracies in the gear geometry.

The potential consequences of not addressing gear tooth profile issues in gearbox design can lead to premature wear, increased noise and vibration, reduced efficiency, and potential system failure. Neglecting to correct the tooth profile can result in uneven load distribution, improper meshing, and accelerated wear on the gear teeth. This can ultimately lead to costly repairs, downtime, and safety hazards in the gearbox system. Therefore, it is essential to prioritize tooth profile correction to ensure the reliable and efficient operation of gear systems.

When addressing gearbox gear tooth fatigue, it is important to consider factors such as lubrication, material properties, surface finish, and operating conditions. Proper lubrication can help reduce friction and wear on the gear teeth, while selecting materials with high fatigue strength and hardness can improve the overall durability of the gears. Additionally, ensuring a smooth surface finish can help minimize stress concentrations and potential crack initiation points. Monitoring operating conditions such as load, speed, and temperature can also help prevent premature fatigue failure of the gear teeth. Regular inspections and maintenance can help identify any signs of fatigue early on and prevent catastrophic failures. By implementing these strategies, gearbox gear tooth fatigue can be effectively managed and mitigated.

To prevent gearbox rusting, it is important to regularly inspect and maintain the gearbox components. This includes checking for any signs of corrosion, such as rust spots or discoloration, and addressing them promptly. Applying a protective coating or lubricant to the gearbox can help prevent moisture from causing rust to form. Keeping the gearbox clean and dry, storing it in a climate-controlled environment, and using rust-resistant materials in the construction of the gearbox can also help prevent rusting. Additionally, using rust inhibitors or desiccants can further protect the gearbox from corrosion. Regularly monitoring the gearbox for any signs of rust and taking proactive measures to prevent it can help extend the lifespan of the gearbox and ensure optimal performance.

The efficiency of a gearbox can indeed be affected by the gearbox gear ratio. The gear ratio in a gearbox refers to the relationship between the number of teeth on the input gear to the number of teeth on the output gear. A higher gear ratio means that the output gear will rotate more times for every rotation of the input gear. This can impact the efficiency of the gearbox as higher gear ratios can lead to increased friction and energy losses due to the increased number of gear engagements. Conversely, lower gear ratios can improve efficiency by reducing the number of gear engagements and minimizing energy losses. Therefore, selecting the appropriate gear ratio is crucial in optimizing the efficiency of a gearbox.

To prevent gearbox oil oxidation, several measures can be taken. One effective method is to use high-quality synthetic oils that contain antioxidants and anti-oxidation additives. Regularly changing the gearbox oil at recommended intervals can also help prevent oxidation. Keeping the gearbox properly sealed and protected from moisture and contaminants can further reduce the risk of oxidation. Additionally, maintaining proper operating temperatures and avoiding excessive heat can help prolong the life of the gearbox oil and prevent oxidation. Monitoring the oil condition regularly through oil analysis can also help detect early signs of oxidation and take corrective actions. Overall, a combination of using high-quality oils, regular maintenance, proper sealing, and monitoring can help prevent gearbox oil oxidation.