When selecting a lubrication grease for gearbox bearings, key factors to consider include the operating conditions of the gearbox, the type of bearing used, the speed and load requirements, and the compatibility with the materials of the bearings. It is essential to choose a grease that can withstand the high temperatures, pressures, and speeds typically found in gearbox applications while providing adequate lubrication and protection to the bearings.

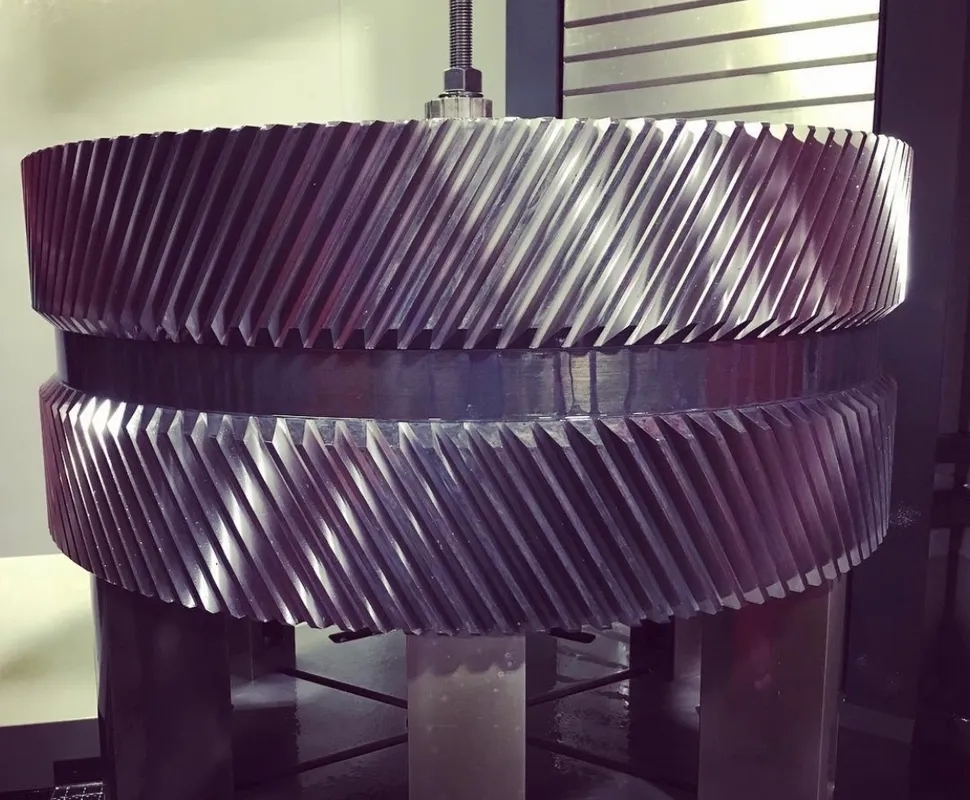

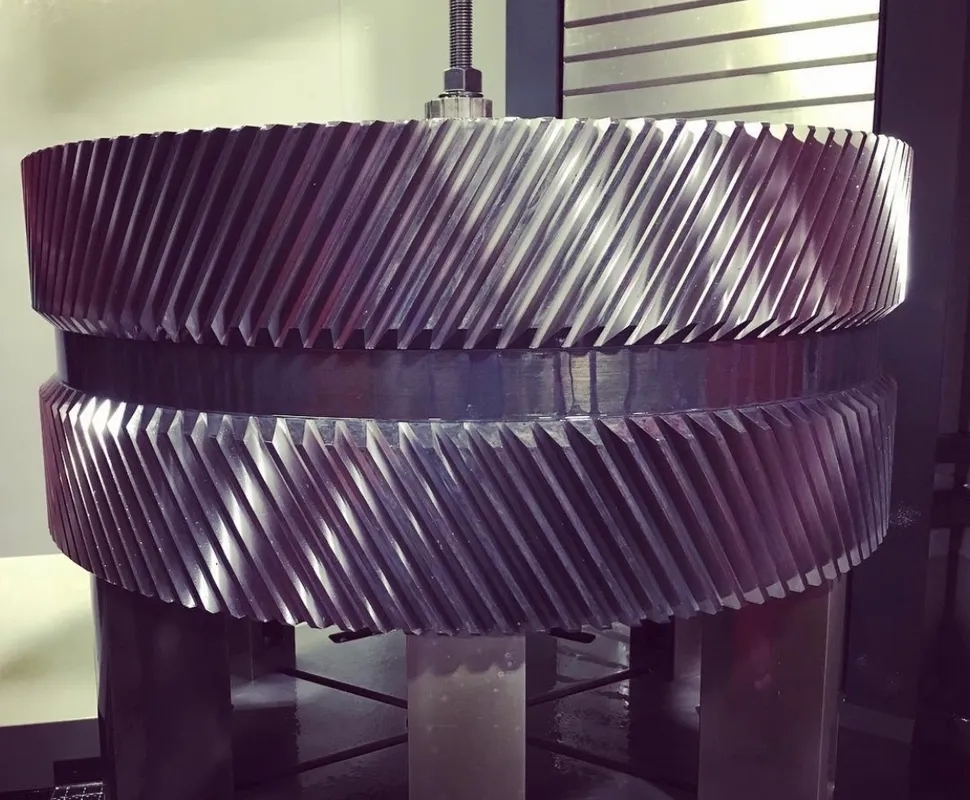

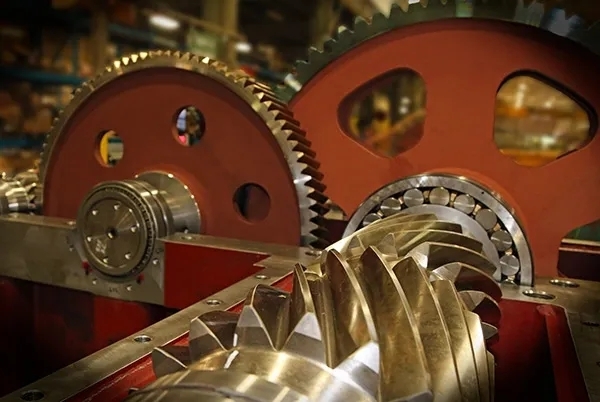

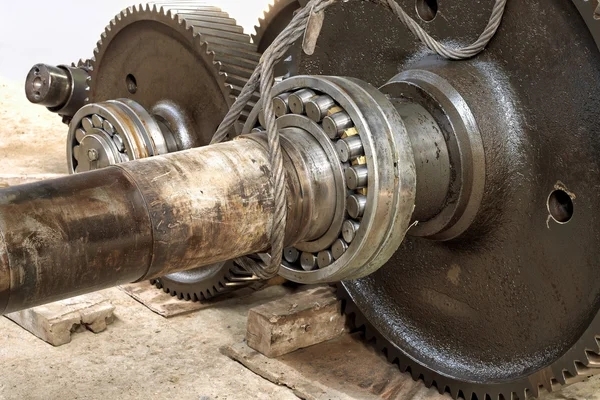

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

The operating temperature of the gearbox bearings is a crucial factor that impacts the choice of lubrication grease. Greases have temperature limits within which they can effectively lubricate bearings. It is important to select a grease that can maintain its viscosity and lubricating properties at the specific operating temperature of the gearbox to ensure optimal performance and longevity of the bearings.

On Monday's show: We talk with NPR's White House Correspondent about the Republican National Convention, then we answer your questions about sleep and gardening--separately, of course.

Posted by on 2024-03-11

Houston ISD is again embroiled in internal strife and public controversy. On Friday, the district released performance ratings to principals. After the Houston Chronicle published details about the ratings, the administration suggested the possibility of legal action against the news outlet and launched an investigation to find the source of the leak.

Posted by on 2024-03-11

Episode: 1132 In which balloons deliver the mail during the Siege of Paris. Today, the very first airmail service is used to break a siege.

Posted by on 2024-03-11

Episode: 1131 John Hunter: idiosyncratic medical pioneer. Today, the history of medicine provides a strange hero.

Posted by on 2024-03-10

The speed and load of the gearbox bearings play a significant role in determining the appropriate grease for lubrication. High-speed and heavy-load applications require greases with high viscosity and extreme pressure additives to prevent wear and ensure smooth operation. It is essential to select a grease that can handle the specific speed and load requirements of the gearbox bearings to prevent premature failure.

The environment in which the gearbox operates also affects the selection of lubrication grease for the bearings. Factors such as moisture, dust, chemicals, and other contaminants can impact the performance of the grease and the bearings. It is important to choose a grease that offers protection against environmental factors and provides long-lasting lubrication in challenging operating conditions.

There are different types of lubrication greases available for gearbox bearings, including lithium-based, calcium-based, polyurea-based, and synthetic greases. These greases differ in performance based on their composition, additives, viscosity, and temperature range. It is essential to select the right type of grease that meets the specific requirements of the gearbox bearings and provides optimal lubrication and protection.

Compatibility between the lubrication grease and the gearbox bearing materials is crucial in the selection process. Using an incompatible grease can lead to chemical reactions, corrosion, and premature wear of the bearings. It is important to choose a grease that is compatible with the materials used in the bearings to ensure proper lubrication and prevent damage to the components.

Testing methods such as ASTM D3336, ASTM D1478, and ASTM D2266 can be used to evaluate the performance of different lubrication greases for gearbox bearings before making a selection. These tests assess the grease's consistency, oxidation stability, extreme pressure properties, and wear protection capabilities. By conducting thorough testing, manufacturers can determine the most suitable grease for their specific gearbox application, ensuring optimal performance and longevity of the bearings.

Determining the appropriate gearbox lubrication interval involves considering factors such as the type of gearbox, operating conditions, temperature, load, and speed. It is important to consult the manufacturer's guidelines and recommendations for the specific gearbox model being used. Regular monitoring of the gearbox's performance, including noise levels, vibration, and temperature, can also help determine when lubrication is needed. Additionally, conducting oil analysis tests can provide valuable insights into the condition of the lubricant and help establish a suitable maintenance schedule. Proper lubrication is essential for ensuring optimal gearbox performance and longevity, so it is crucial to follow a proactive maintenance approach based on the unique requirements of the equipment in use.

One way to detect gearbox vibration issues is by conducting regular vibration analysis using specialized equipment such as accelerometers, tachometers, and vibration meters. By monitoring the frequency, amplitude, and overall vibration levels of the gearbox components, technicians can identify any abnormal vibrations that may indicate potential issues such as misalignment, worn bearings, gear tooth damage, or lubrication problems. Additionally, performing visual inspections of the gearbox for signs of wear, corrosion, or leaks can also help in detecting vibration issues early on. It is important to establish baseline vibration levels for comparison and to follow manufacturer guidelines for maintenance and lubrication to prevent excessive vibration and prolong the life of the gearbox.

Indicators of gearbox gear mesh misalignment can include abnormal noise during operation, such as grinding, clicking, or whining sounds. Other signs may include vibration, increased wear on gear teeth, and overheating of the gearbox. In some cases, there may be a decrease in overall efficiency and performance of the gearbox. It is important to address gear mesh misalignment promptly to prevent further damage to the gearbox and ensure optimal functioning of the equipment. Regular maintenance and inspection can help identify and correct misalignment issues before they escalate.

The efficiency of a gearbox can indeed be influenced by the design of the gearbox housing. Factors such as the material used, the shape and size of the housing, the presence of cooling mechanisms, and the overall construction can all impact the performance of the gearbox. A well-designed gearbox housing can help to reduce friction, improve heat dissipation, enhance lubrication distribution, and minimize vibration, all of which can contribute to higher efficiency and smoother operation of the gearbox. Additionally, features such as proper sealing and alignment within the housing can also play a crucial role in maintaining optimal efficiency levels. Therefore, gearbox manufacturers often pay close attention to the housing design to ensure that it complements the internal components and contributes to overall performance.

To prevent gearbox contamination from external debris, several measures can be taken. One effective method is to install high-quality seals and gaskets to create a barrier between the gearbox and the surrounding environment. Regularly inspecting and maintaining these seals can help ensure they are functioning properly. Additionally, implementing proper ventilation systems can help prevent the buildup of dust and dirt around the gearbox. Keeping the surrounding area clean and free of debris can also help reduce the risk of contamination. Using filters and screens on any openings or vents can further prevent debris from entering the gearbox. Overall, a combination of these measures can help protect the gearbox from external contamination and ensure optimal performance.