Thermal expansion compensation in gearbox systems refers to the measures taken to account for the expansion and contraction of materials due to changes in temperature. This is crucial in gearboxes as temperature variations can lead to misalignments, increased friction, and potential damage to components if not properly addressed.

Thermal expansion can significantly impact the performance and lifespan of gearboxes. As materials heat up, they expand, causing misalignments and increased stress on components. This can lead to decreased efficiency, increased wear and tear, and ultimately, premature failure of the gearbox if thermal expansion is not adequately compensated for.

More than 16,000 additional babies were born in Texas in 2022 compared to 2021 after the state banned almost all abortions after six weeks of pregnancy, according to a University of Houston analysis of 2022 fertility data.

Posted by on 2024-03-11

On Sunday, Maj. Gen. Ray Shields, the adjutant general of New York, said the bureau was mourning the deaths of Grassia, Frankoski and Luna.

Posted by on 2024-03-11

That major turnout comes as Rodeo Houston saw significantly lower attendance than last year's event nearing the halfway point last week.

Posted by on 2024-03-11

As the Houston Livestock Show and Rodeo wraps up, many are focused on the area's cowboy culture. Black cattle hands living just outside the city played a key part in that history.

Posted by on 2024-03-11

Common methods used to compensate for thermal expansion in gearboxes include the use of materials with low thermal expansion coefficients, incorporating flexible couplings or mounts, designing for proper clearance and tolerances, and implementing cooling systems to regulate temperature and minimize thermal effects on the gearbox components.

Backlash in gearboxes refers to the clearance between mating gear teeth. When thermal expansion occurs, it can affect the backlash and lead to issues such as increased noise, vibration, and reduced efficiency. Proper thermal expansion compensation is essential to maintain the optimal backlash and ensure smooth operation of the gearbox.

Manufacturers determine the appropriate amount of thermal expansion compensation for a gearbox through careful analysis of the materials used, operating temperatures, and expected thermal variations. Finite element analysis and computer simulations are often employed to predict the effects of thermal expansion and optimize the design for minimal impact on gearbox performance.

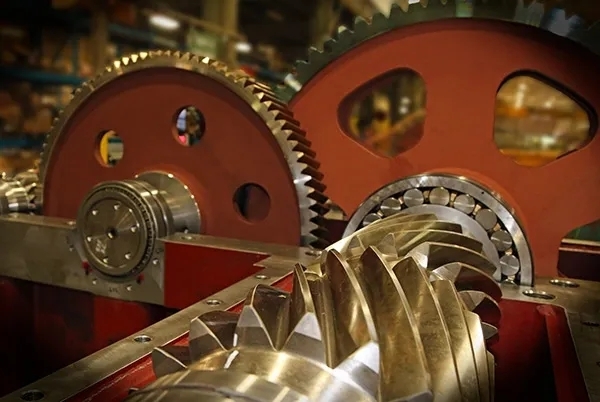

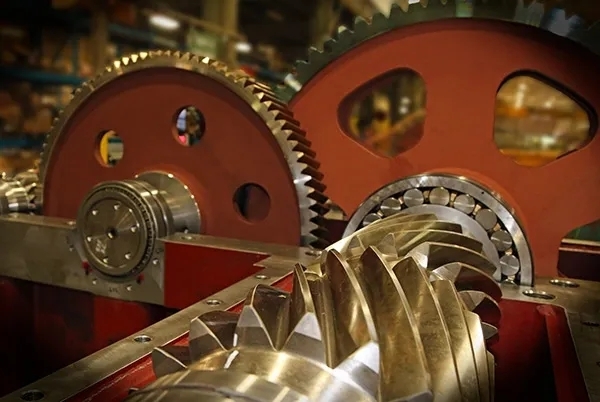

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

Innovative techniques for gearbox thermal expansion compensation are continuously being developed, such as the use of shape memory alloys that can adjust their shape in response to temperature changes, or the integration of sensors and actuators to actively control thermal expansion effects in real-time. These advanced methods aim to further improve gearbox performance and reliability in varying operating conditions.

Not properly compensating for thermal expansion in gearboxes can result in a range of consequences, including increased friction, accelerated wear on components, reduced efficiency, and potential catastrophic failure. Neglecting thermal expansion compensation can lead to costly repairs, downtime, and safety hazards in industrial applications where gearboxes are critical components. It is essential to address thermal expansion proactively to ensure the longevity and optimal performance of gearbox systems.

Gearbox overloading can lead to a variety of potential risks, including increased wear and tear on the gears, bearings, and other components within the system. This can result in decreased efficiency, increased heat generation, and ultimately, premature failure of the gearbox. Additionally, overloading can cause excessive vibration, noise, and potential damage to surrounding equipment. In extreme cases, gearbox overloading can lead to catastrophic failure, posing safety risks to personnel and causing costly downtime for repairs and replacements. It is important to monitor and maintain proper load levels to prevent these risks and ensure the longevity and performance of the gearbox.

Gearbox performance can indeed be affected by gearbox mounting issues. When the gearbox is not properly mounted, it can lead to misalignment, increased vibration, and premature wear on the gears and bearings. This can result in decreased efficiency, increased noise levels, and potential damage to other components within the transmission system. It is crucial to ensure that the gearbox is securely and accurately mounted to prevent any negative impacts on its overall performance and longevity. Regular maintenance and inspections of the gearbox mounting system are essential to avoid any potential issues that may arise from improper installation or mounting.

To prevent gearbox water ingress, several measures can be taken to ensure the integrity of the system. One effective method is to regularly inspect and maintain the gearbox seals to ensure they are in good condition and free from any cracks or damage. Additionally, applying a waterproof sealant or coating to vulnerable areas can help create an extra barrier against water penetration. Installing a breather vent with a filter can also help prevent moisture from entering the gearbox while still allowing for pressure equalization. Furthermore, ensuring proper drainage around the gearbox area can help prevent water from pooling and seeping into the system. Regularly monitoring the gearbox for any signs of water ingress, such as milky oil or corrosion, can also help detect any issues early on and prevent further damage.

Detecting gearbox oil oxidation can be done by monitoring the oil's color, viscosity, and odor. Oxidized gearbox oil may appear darker in color, have a thicker consistency, and emit a burnt or acrid smell. Additionally, testing the oil for acidity levels can also indicate oxidation. Other signs of gearbox oil oxidation include increased levels of sludge or varnish in the oil, decreased lubricating properties, and potential damage to the gearbox components. Regular oil analysis and maintenance can help prevent and detect gearbox oil oxidation before it causes significant damage to the system.