Nitriding is a surface treatment method that offers numerous benefits for gearbox gear teeth. By introducing nitrogen into the surface of the material, nitriding creates a hard and wear-resistant layer that improves the overall durability and longevity of the gear teeth. This process also enhances the fatigue strength of the gear teeth, making them more resistant to wear and damage over time. Additionally, nitriding can improve the surface hardness of the gear teeth, leading to better performance and efficiency in gearbox operations.

Shot peening is a surface treatment technique that can significantly improve the fatigue strength of gearbox gear tooth surfaces. By bombarding the surface of the gear teeth with small metal particles at high velocities, shot peening induces compressive residual stresses in the material. These compressive stresses help to prevent the initiation and propagation of cracks, increasing the fatigue life of the gear teeth. As a result, gearbox gear teeth treated with shot peening exhibit improved resistance to fatigue failure and have a longer service life.

Each month, we turn to the Garden Club of Houston’s Meg Tapp to offer advice for Houston area gardeners.

Posted by on 2024-03-11

NFL free agency is underway, with teams able to negotiate with players now. They can start signing contracts Wednesday.

Posted by on 2024-03-11

Only about 40 minutes of footage made it out to the world in real time because of poor connections, but when Chernov and his colleagues were finally able to leave, he decided he needed to do something with the 30-some hours they had on tape.

Posted by on 2024-03-11

More than 16,000 additional babies were born in Texas in 2022 compared to 2021 after the state banned almost all abortions after six weeks of pregnancy, according to a University of Houston analysis of 2022 fertility data.

Posted by on 2024-03-11

Carburizing is a surface treatment method that can be used to increase the wear resistance of gearbox gear teeth. By introducing carbon into the surface of the material, carburizing forms a hard and wear-resistant layer that can withstand abrasive wear and frictional forces. This process improves the surface hardness of the gear teeth, making them more resistant to wear and extending their lifespan. Carburizing is an effective way to enhance the wear resistance of gearbox gear teeth and improve their overall performance in demanding operating conditions.

Case hardening plays a crucial role in enhancing the surface hardness of gearbox gear teeth. By heating the material to a high temperature and then quenching it in a hardening medium, case hardening forms a hard outer layer on the surface of the gear teeth. This hardened layer increases the wear resistance and durability of the gear teeth, making them more capable of withstanding the stresses and forces experienced during gearbox operation. Case hardening is an effective surface treatment method for improving the surface hardness and overall performance of gearbox gear teeth.

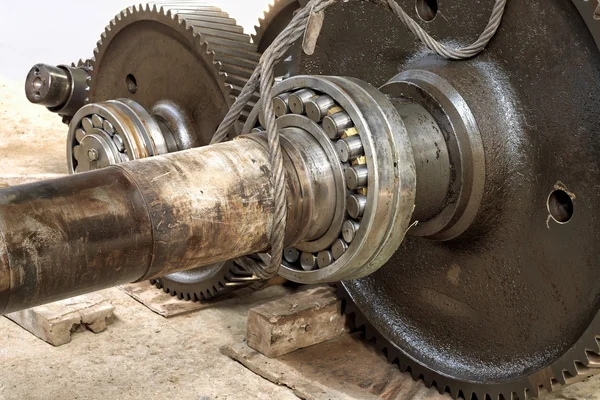

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

The surface roughness of gearbox gear teeth can have a significant impact on their performance and efficiency. A smooth surface finish on the gear teeth reduces friction and wear, leading to improved efficiency and reduced energy consumption in the gearbox. On the other hand, rough surfaces can increase friction, wear, and noise levels, decreasing the overall performance of the gearbox. Therefore, maintaining the proper surface roughness of gear teeth through appropriate surface treatments is essential for ensuring optimal gearbox operation and longevity.

There are environmentally-friendly surface treatment options available for gearbox gear teeth that prioritize sustainability and eco-friendliness. Processes such as plasma nitriding and ion implantation offer surface treatment solutions that do not involve the use of harmful chemicals or produce hazardous waste. These environmentally-friendly treatments provide the same benefits of improved wear resistance, surface hardness, and performance for gearbox gear teeth while minimizing the impact on the environment. By choosing sustainable surface treatment options, manufacturers can enhance the durability and lifespan of gearbox gear teeth without compromising environmental responsibility.

The choice of surface treatment has a significant impact on the overall durability and lifespan of gearbox gear teeth. Surface treatments such as nitriding, shot peening, carburizing, and case hardening can improve the wear resistance, fatigue strength, and surface hardness of gear teeth, leading to longer service life and better performance. By selecting the appropriate surface treatment method based on the specific requirements and operating conditions of the gearbox, manufacturers can ensure that the gear teeth are able to withstand the demands of their application and maintain optimal performance over time. Ultimately, the right surface treatment choice can significantly enhance the durability and lifespan of gearbox gear teeth, reducing maintenance costs and downtime in the long run.

Gearbox breathers play a crucial role in maintenance by preventing the buildup of pressure inside the gearbox, which can lead to leaks, seal failures, and other issues. These breathers allow for the release of excess air and gases that can accumulate during operation, helping to maintain optimal operating conditions and prolonging the lifespan of the gearbox components. By ensuring proper ventilation and preventing contamination from entering the gearbox, breathers help to reduce the risk of premature wear and damage, ultimately contributing to the overall efficiency and reliability of the system. Regular inspection and maintenance of gearbox breathers are essential to ensure they are functioning correctly and effectively protecting the gearbox from potential harm.

Assessing gearbox lubrication system performance involves monitoring various key indicators such as oil viscosity, temperature, pressure, and contamination levels. Regularly checking the oil level and quality, as well as inspecting for any leaks or unusual noises, can help determine the effectiveness of the lubrication system. Additionally, analyzing oil samples for wear particles and conducting vibration analysis can provide valuable insights into the overall health of the gearbox. Utilizing advanced technologies like online condition monitoring systems and thermal imaging can further enhance the assessment of gearbox lubrication system performance. By integrating these various monitoring techniques, maintenance professionals can ensure optimal lubrication system functionality and prevent potential equipment failures.