Corrosion in gearbox components can be caused by a variety of factors, including exposure to moisture, chemicals, and high temperatures. Moisture can lead to the formation of rust on metal surfaces, while chemicals can react with the materials in the gearbox, causing corrosion. High temperatures can accelerate the corrosion process by increasing the rate of chemical reactions. Additionally, friction between moving parts can wear down protective coatings, leaving the components vulnerable to corrosion.

The use of protective coatings can help prevent corrosion in gearbox components by creating a barrier between the metal surface and the corrosive elements in the environment. These coatings can be made of materials such as zinc, aluminum, or polymer-based compounds that are designed to resist corrosion. By applying these coatings to gearbox components, manufacturers can extend the lifespan of the equipment and reduce the need for costly repairs or replacements.

On Sunday, Maj. Gen. Ray Shields, the adjutant general of New York, said the bureau was mourning the deaths of Grassia, Frankoski and Luna.

Posted by on 2024-03-11

That major turnout comes as Rodeo Houston saw significantly lower attendance than last year's event nearing the halfway point last week.

Posted by on 2024-03-11

As the Houston Livestock Show and Rodeo wraps up, many are focused on the area's cowboy culture. Black cattle hands living just outside the city played a key part in that history.

Posted by on 2024-03-11

On Monday's show: We talk with NPR's White House Correspondent about the Republican National Convention, then we answer your questions about sleep and gardening--separately, of course.

Posted by on 2024-03-11

Houston ISD is again embroiled in internal strife and public controversy. On Friday, the district released performance ratings to principals. After the Houston Chronicle published details about the ratings, the administration suggested the possibility of legal action against the news outlet and launched an investigation to find the source of the leak.

Posted by on 2024-03-11

Environmental factors play a significant role in the corrosion of gearbox components. Exposure to saltwater, humidity, and pollutants in the air can all contribute to the degradation of metal surfaces. Saltwater, in particular, is highly corrosive and can quickly eat away at gearbox components if not properly protected. In industrial settings, chemicals and fumes from manufacturing processes can also accelerate the corrosion process.

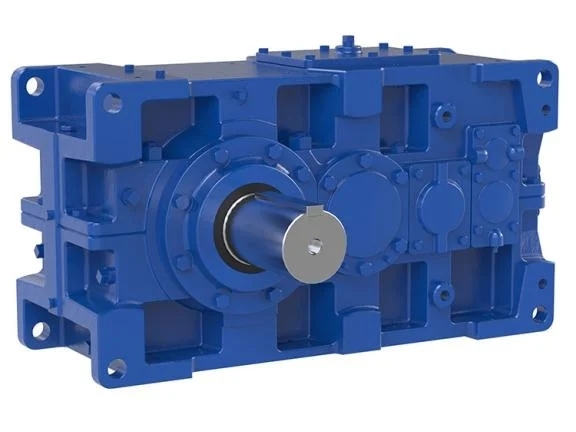

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

Specific maintenance practices can help prevent corrosion in gearbox components. Regular inspections to check for signs of corrosion, cleaning and lubricating moving parts, and applying protective coatings are all important steps in maintaining the integrity of gearbox components. Additionally, storing equipment in a dry and controlled environment can help reduce the risk of corrosion from environmental factors.

Different types of lubricants can impact the corrosion resistance of gearbox components. Some lubricants contain additives that provide additional protection against corrosion, while others may actually promote corrosion if not compatible with the materials in the gearbox. It is important to use lubricants that are specifically designed for gearbox applications and to follow manufacturer recommendations for maintenance and lubrication schedules.

The material composition of gearbox components can indeed affect their susceptibility to corrosion. For example, stainless steel is known for its corrosion resistance and is often used in gearbox components that are exposed to harsh environments. On the other hand, materials like cast iron or carbon steel may be more prone to corrosion and require additional protective measures to prevent degradation. Choosing the right materials for gearbox components is crucial in ensuring their long-term performance and durability.

Innovative technologies are being used to prevent corrosion in gearbox components, such as nanocoatings, electroplating, and corrosion-resistant alloys. Nanocoatings can provide a thin, protective layer that is highly resistant to corrosion, while electroplating involves applying a metal coating to the surface of gearbox components to enhance their corrosion resistance. Corrosion-resistant alloys, on the other hand, are specifically designed to withstand harsh environments and can be used in place of traditional materials to improve the longevity of gearbox components. These technologies are continuously evolving to provide better protection against corrosion and extend the lifespan of gearbox equipment.

When determining the appropriate gearbox lubricant volume, it is important to consider factors such as gear type, operating conditions, and manufacturer recommendations. The volume of lubricant needed will vary depending on the size and design of the gearbox, as well as the speed and load at which it operates. It is crucial to consult the gearbox manual or contact the manufacturer to determine the correct lubricant volume for optimal performance and longevity. Additionally, factors such as temperature, viscosity, and oil type should be taken into account when calculating the appropriate volume of lubricant to ensure proper lubrication and protection of the gearbox components. Regular maintenance and monitoring of the lubricant level are also essential to prevent damage and ensure smooth operation of the gearbox.

When addressing gearbox lubrication blockages, it is important to first identify the root cause of the issue. Common reasons for blockages include contamination, inadequate lubrication, or mechanical failures. To resolve the blockage, one can utilize methods such as flushing the system, replacing the lubricant, cleaning filters, or repairing any damaged components. It is crucial to follow manufacturer guidelines and use appropriate tools and equipment to ensure proper maintenance and prevent future blockages. Regular inspections and maintenance routines can help detect and address blockages before they escalate into more severe problems. By addressing gearbox lubrication blockages promptly and effectively, one can ensure optimal performance and longevity of the equipment.

One way to identify gearbox seal leaks is to look for signs of oil or fluid dripping or pooling underneath the vehicle. Other indicators may include a decrease in fluid levels, visible cracks or damage to the seal itself, and a burning smell coming from the gearbox. Additionally, a visual inspection of the gearbox housing and surrounding components may reveal signs of leakage, such as oil stains or residue. It is important to address gearbox seal leaks promptly to prevent further damage to the transmission system and ensure optimal performance of the vehicle.

Filtration systems play a crucial role in gearbox maintenance by removing contaminants such as dirt, debris, and metal particles from the lubricating oil. These systems help prevent wear and tear on gearbox components, improve overall performance, and extend the lifespan of the gearbox. By capturing and filtering out harmful particles, filtration systems ensure that the lubricating oil remains clean and effective in reducing friction and heat within the gearbox. Regular maintenance of filtration systems is essential to ensure optimal gearbox performance and prevent costly repairs or replacements. Proper filtration also helps maintain the viscosity and integrity of the lubricating oil, ensuring smooth operation and efficient power transmission within the gearbox.

The performance of a gearbox can indeed be affected by humidity levels. High levels of humidity can lead to increased moisture within the gearbox, potentially causing corrosion, rust, and lubrication breakdown. This can result in decreased efficiency, increased friction, and ultimately, a decrease in overall performance. It is important to monitor and control humidity levels in the environment where the gearbox is located to ensure optimal functioning and longevity. Additionally, proper maintenance and regular inspections can help mitigate the negative effects of humidity on gearbox performance.