Gearbox housings can be coated with various types of coatings, including epoxy coatings, polyurethane coatings, ceramic coatings, and zinc coatings. Each type of coating offers different benefits in terms of durability, corrosion resistance, and heat resistance, depending on the specific requirements of the gearbox housing.

Powder coating and liquid coating are two common methods used for coating gearbox housings. Powder coating involves applying a dry powder to the surface of the housing, which is then cured under heat to form a protective layer. Liquid coating, on the other hand, involves applying a liquid coating to the surface and allowing it to dry. Powder coating is often preferred for its durability, resistance to chipping, and environmental benefits, while liquid coating may offer more flexibility in terms of color options.

After Gov. Greg Abbott said there should be consequences for the suspended cases via X, Whitmire suggested the state send money to Houston to help HPD.

Posted by on 2024-03-11

“I was prepared to roll out some improvements and reforms, but was unsatisfied with the product that I received from Public Works yesterday,” said Mayor Whitmire during Tuesday’s public session meeting. “So I sent them back to the drawing board.”

Posted by on 2024-03-11

Houston officials and community members are touting the success of the barricades they say have driven away prostitutes and those actively seeking them.

Posted by on 2024-03-11

The 54-year-old Anderson, known for feature-length films such as "Rushmore," "The Royal Tenenbaums," "Fantastic Mr. Fox" and "Asteroid City," won in the Best Live Action Short Film category for "The Wonderful Story of Henry Sugar." He had previously been nominated for seven Academy Awards.

Posted by on 2024-03-11

Attorney General Ken Paxton has now targeted seven school districts over alleged electioneering in what he calls an effort to stop elections from being “illegally swayed by public officials improperly using state resources.” Those school districts are responding.

Posted by on 2024-03-11

In high-temperature environments, it is recommended to use coatings that can withstand elevated temperatures without degrading. Ceramic coatings, such as thermal barrier coatings or high-temperature resistant coatings, are often used for gearbox housings in high-temperature environments to provide thermal insulation and protection against heat-related damage.

Thermal spray coatings offer several advantages when used on gearbox housings. These coatings can provide enhanced wear resistance, corrosion protection, and thermal insulation. Additionally, thermal spray coatings can be applied to complex shapes and surfaces, making them suitable for gearbox housings with intricate designs.

Gearbox housings can be coated with anti-corrosion coatings to protect them from rust and corrosion. Zinc coatings, such as zinc plating or zinc-rich paints, are commonly used for their excellent corrosion resistance properties. These coatings create a barrier between the metal surface of the gearbox housing and corrosive elements, preventing oxidation and extending the lifespan of the housing.

Environmentally-friendly coating options are available for gearbox housings to reduce the impact on the environment. Water-based coatings, powder coatings, and low-VOC (volatile organic compound) coatings are some of the eco-friendly options that can be used to coat gearbox housings. These coatings are designed to minimize harmful emissions and reduce the use of hazardous chemicals during the coating process.

The choice of coatings can significantly impact the overall performance and lifespan of gearbox housings. Properly selected coatings can provide protection against wear, corrosion, and heat, extending the lifespan of the gearbox housing. Additionally, coatings can improve the efficiency of the gearbox by reducing friction and improving heat dissipation. Regular maintenance and inspection of the coatings are essential to ensure optimal performance and longevity of gearbox housings.

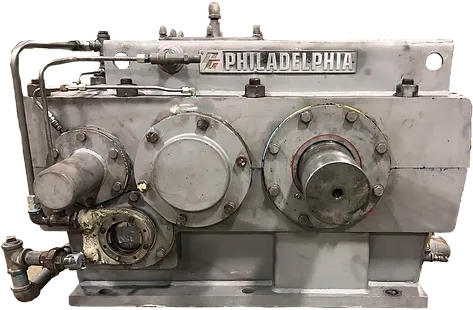

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

Determining the appropriate gearbox lubrication interval involves considering factors such as the type of gearbox, operating conditions, temperature, load, and speed. It is important to consult the manufacturer's guidelines and recommendations for the specific gearbox model being used. Regular monitoring of the gearbox's performance, including noise levels, vibration, and temperature, can also help determine when lubrication is needed. Additionally, conducting oil analysis tests can provide valuable insights into the condition of the lubricant and help establish a suitable maintenance schedule. Proper lubrication is essential for ensuring optimal gearbox performance and longevity, so it is crucial to follow a proactive maintenance approach based on the unique requirements of the equipment in use.

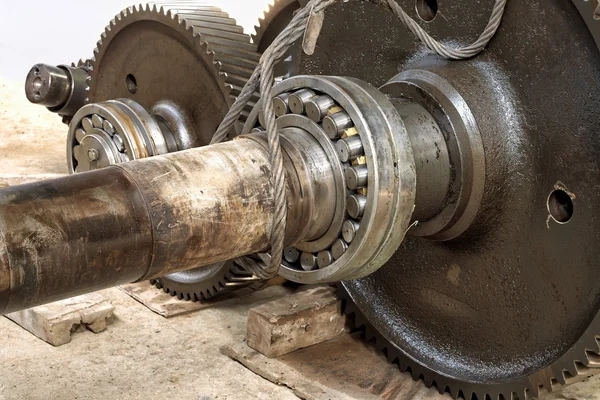

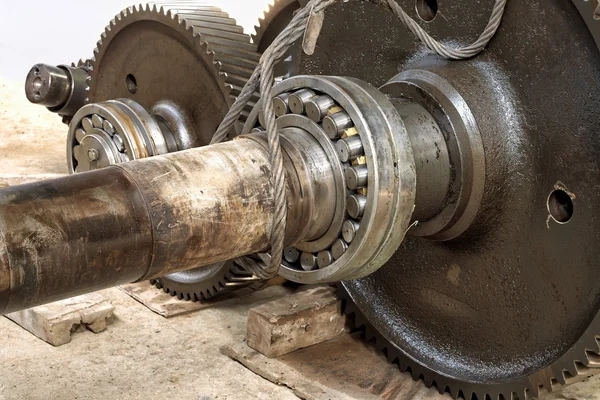

One way to detect gearbox vibration issues is by conducting regular vibration analysis using specialized equipment such as accelerometers, tachometers, and vibration meters. By monitoring the frequency, amplitude, and overall vibration levels of the gearbox components, technicians can identify any abnormal vibrations that may indicate potential issues such as misalignment, worn bearings, gear tooth damage, or lubrication problems. Additionally, performing visual inspections of the gearbox for signs of wear, corrosion, or leaks can also help in detecting vibration issues early on. It is important to establish baseline vibration levels for comparison and to follow manufacturer guidelines for maintenance and lubrication to prevent excessive vibration and prolong the life of the gearbox.

Indicators of gearbox gear mesh misalignment can include abnormal noise during operation, such as grinding, clicking, or whining sounds. Other signs may include vibration, increased wear on gear teeth, and overheating of the gearbox. In some cases, there may be a decrease in overall efficiency and performance of the gearbox. It is important to address gear mesh misalignment promptly to prevent further damage to the gearbox and ensure optimal functioning of the equipment. Regular maintenance and inspection can help identify and correct misalignment issues before they escalate.

The efficiency of a gearbox can indeed be influenced by the design of the gearbox housing. Factors such as the material used, the shape and size of the housing, the presence of cooling mechanisms, and the overall construction can all impact the performance of the gearbox. A well-designed gearbox housing can help to reduce friction, improve heat dissipation, enhance lubrication distribution, and minimize vibration, all of which can contribute to higher efficiency and smoother operation of the gearbox. Additionally, features such as proper sealing and alignment within the housing can also play a crucial role in maintaining optimal efficiency levels. Therefore, gearbox manufacturers often pay close attention to the housing design to ensure that it complements the internal components and contributes to overall performance.