Properly reassembling a gearbox involves several key steps to ensure its functionality and longevity. First, it is crucial to thoroughly clean all components to remove any dirt or debris that could affect performance. Next, carefully inspect each part for any signs of wear or damage, replacing as necessary. Then, refer to the manufacturer's manual to correctly position and secure each component in the gearbox. Finally, torque all bolts to the specified settings to prevent any issues with the gearbox in the future.

Following the manufacturer's specifications when reassembling a gearbox is of utmost importance. These specifications are designed to ensure the gearbox functions optimally and safely. Deviating from these guidelines could lead to improper alignment, increased wear and tear, or even complete gearbox failure. By adhering to the manufacturer's instructions, one can guarantee that the gearbox will operate as intended and avoid any potential issues down the line.

On Wednesday's show: We discuss the latest developments in politics, including whether runoffs ever have dramatically different results. Then we consider if we are ready for the next major public health emergency.

Posted by on 2024-03-13

Episode: 2998 Test Tube Evolution. Today, evolution in a test tube.

Posted by on 2024-03-13

Dr. Talat Jehan Khan, a pediatrician for Texas Children's Hospital, was stabbed to death Oct. 28 in an outdoor common area at Alys Luxury Living in Conroe. The man accused of killing her is jailed and faces a murder charge.

Posted by on 2024-03-12

The university is partnering with the Ibn Sina Foundation and the OakBend Medical Center in Richmond.

Posted by on 2024-03-12

Essential tools for efficiently reassembling a gearbox include torque wrenches, socket sets, screwdrivers, pliers, and a gearbox jack or stand. These tools are necessary for disassembling and reassembling the gearbox components, tightening bolts to the correct specifications, and ensuring proper alignment. Having the right tools on hand can make the reassembly process smoother and more precise.

To ensure all components are properly aligned during gearbox reassembly, one can use alignment pins, dowel pins, or alignment marks on the gearbox housing and components. These aids help guide the correct positioning of each part, preventing misalignment that could lead to operational issues. Additionally, double-checking the alignment of components before securing them in place is crucial to avoid any potential problems with the gearbox.

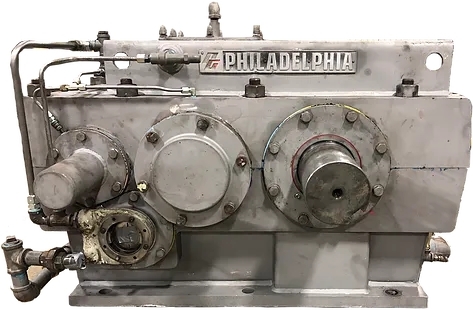

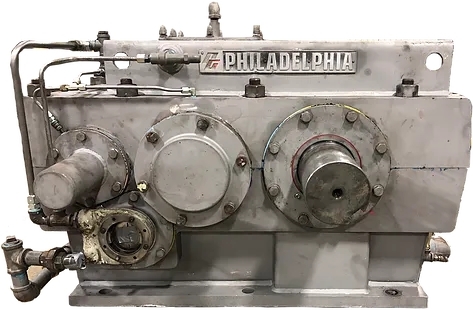

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

Common mistakes to avoid when reassembling a gearbox include over-tightening bolts, skipping steps in the reassembly process, neglecting to replace worn components, and not properly lubricating moving parts. Overlooking these aspects can result in premature gearbox failure, decreased performance, or safety hazards. It is essential to take the time to reassemble the gearbox correctly to ensure its reliability and longevity.

It is necessary to lubricate all components during gearbox reassembly to reduce friction, prevent wear, and ensure smooth operation. Using the appropriate lubricants recommended by the manufacturer will help extend the lifespan of the gearbox and maintain its efficiency. Proper lubrication also aids in heat dissipation and noise reduction, contributing to the overall performance of the gearbox.

To test the gearbox after reassembly and ensure it is functioning correctly, one can perform a series of checks and inspections. This includes testing the gearbox in different gears to verify smooth shifting, listening for any unusual noises or vibrations, checking for leaks, and monitoring the gearbox temperature. Additionally, conducting a road test under various driving conditions can help confirm that the gearbox is operating as expected. If any issues are detected during testing, further adjustments or repairs may be necessary to address them.

To prevent gearbox contamination from external debris, several measures can be taken. One effective method is to install high-quality seals and gaskets to create a barrier between the gearbox and the surrounding environment. Regularly inspecting and maintaining these seals can help ensure they are functioning properly. Additionally, implementing proper ventilation systems can help prevent the buildup of dust and dirt around the gearbox. Keeping the surrounding area clean and free of debris can also help reduce the risk of contamination. Using filters and screens on any openings or vents can further prevent debris from entering the gearbox. Overall, a combination of these measures can help protect the gearbox from external contamination and ensure optimal performance.

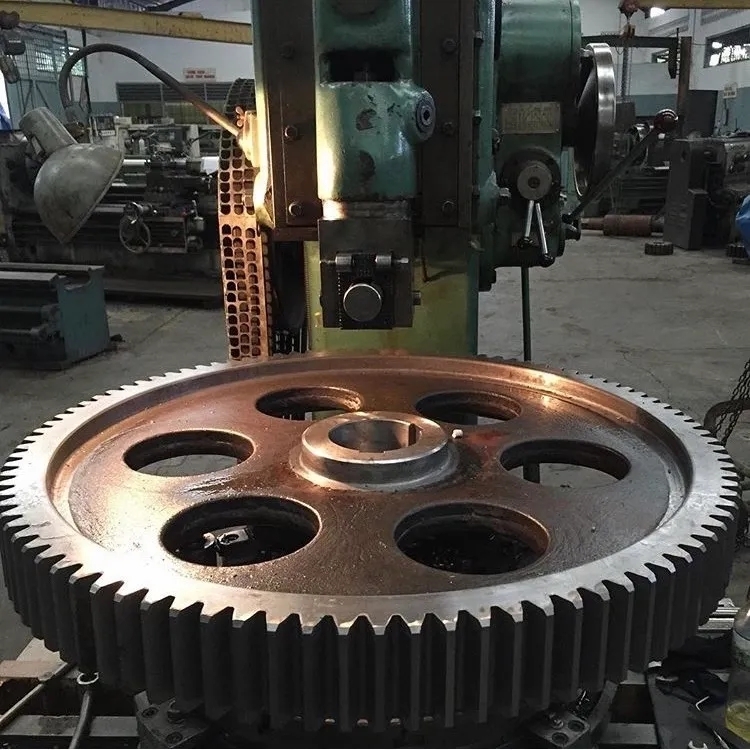

When addressing gearbox gear tooth pitting, it is important to first identify the root cause of the issue, which can include factors such as improper lubrication, misalignment, overloading, or material defects. Once the cause is determined, the gears may need to be repaired or replaced to prevent further damage and ensure optimal performance. Common methods for addressing gear tooth pitting include grinding, shot peening, or applying surface treatments such as nitriding or carburizing to improve the hardness and wear resistance of the gears. Regular maintenance and monitoring of the gearbox can also help prevent future instances of gear tooth pitting.

When selecting the appropriate gearbox lubricant viscosity, it is important to consider factors such as operating temperature, load, speed, and gear type. The viscosity of the lubricant should be chosen based on the manufacturer's recommendations and specifications for the specific gearbox in question. It is crucial to ensure that the lubricant provides adequate film thickness to prevent metal-to-metal contact and reduce friction and wear. Additionally, the lubricant should have good thermal stability and resistance to oxidation to maintain its performance over time. By selecting the right viscosity lubricant, the gearbox can operate efficiently and effectively, prolonging its lifespan and reducing the risk of breakdowns or failures.

When it comes to high-speed applications, gearboxes that are best suited are typically those with helical gears, planetary gears, or hypoid gears. These types of gearboxes are designed to handle the increased speeds and torque requirements often found in high-speed applications. Helical gears provide smooth and quiet operation, while planetary gears offer high efficiency and compact design. Hypoid gears are known for their ability to handle heavy loads and high speeds. Additionally, gearboxes with precision machining, high-quality materials, and advanced lubrication systems are also ideal for high-speed applications to ensure optimal performance and durability. Overall, selecting a gearbox with the right gear type and features is crucial for achieving reliable and efficient operation in high-speed applications.

Gearbox overloading can lead to a variety of potential risks, including increased wear and tear on the gears, bearings, and other components within the system. This can result in decreased efficiency, increased heat generation, and ultimately, premature failure of the gearbox. Additionally, overloading can cause excessive vibration, noise, and potential damage to surrounding equipment. In extreme cases, gearbox overloading can lead to catastrophic failure, posing safety risks to personnel and causing costly downtime for repairs and replacements. It is important to monitor and maintain proper load levels to prevent these risks and ensure the longevity and performance of the gearbox.