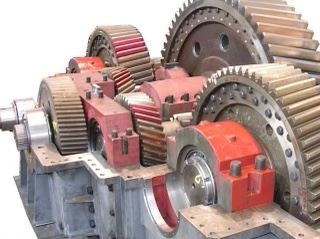

In gearbox housing manufacturing, different types of reinforcement techniques are commonly used to enhance the strength and durability of the component. Some of the most common techniques include ribbing, gusseting, bracing, and filleting. These techniques help distribute stress and load more evenly throughout the housing, reducing the risk of failure or deformation under operating conditions.

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

The use of ribbing in gearbox housing plays a crucial role in improving its strength. Ribbing involves adding raised sections or ridges to the housing, which helps to increase its stiffness and resistance to bending or torsional forces. By incorporating ribbing into the design, engineers can effectively reinforce critical areas of the housing and prevent structural failure under heavy loads or vibrations.

More than 16,000 additional babies were born in Texas in 2022 compared to 2021 after the state banned almost all abortions after six weeks of pregnancy, according to a University of Houston analysis of 2022 fertility data.

Posted by on 2024-03-11

On Sunday, Maj. Gen. Ray Shields, the adjutant general of New York, said the bureau was mourning the deaths of Grassia, Frankoski and Luna.

Posted by on 2024-03-11

That major turnout comes as Rodeo Houston saw significantly lower attendance than last year's event nearing the halfway point last week.

Posted by on 2024-03-11

As the Houston Livestock Show and Rodeo wraps up, many are focused on the area's cowboy culture. Black cattle hands living just outside the city played a key part in that history.

Posted by on 2024-03-11

Gussets are another important element in reinforcing gearbox housing. Gussets are triangular or trapezoidal plates that are welded or bolted to the housing to provide additional support and strength. These reinforcements help to distribute stress more evenly across the housing, reducing the risk of localized failure or cracking. By strategically placing gussets in key areas, designers can significantly improve the overall structural integrity of the gearbox housing.

The material used in gearbox housing can have a significant impact on the reinforcement techniques that are employed. Different materials have varying properties, such as strength, stiffness, and ductility, which can influence the choice of reinforcement method. For example, a gearbox housing made of aluminum may require different reinforcement techniques than one made of steel, due to the material's unique characteristics and behavior under load.

Designers determine the optimal reinforcement technique for a specific gearbox housing design by considering factors such as the expected load, operating conditions, material properties, and manufacturing constraints. Through finite element analysis (FEA) and computer-aided design (CAD) simulations, engineers can evaluate different reinforcement options and select the most effective solution to ensure the housing meets performance requirements and safety standards.

In recent years, there have been advancements in innovative reinforcement techniques used in gearbox housing manufacturing. For example, additive manufacturing technologies, such as 3D printing, allow for the creation of complex geometries and internal structures that can enhance the strength and stiffness of the housing. Additionally, composite materials, such as carbon fiber or fiberglass, are being increasingly used to reinforce gearbox housing, offering a lightweight and high-strength alternative to traditional metal reinforcements.

The choice of reinforcement techniques in gearbox housing manufacturing can have a significant impact on the overall performance and durability of the component. By effectively reinforcing critical areas of the housing, engineers can improve its resistance to fatigue, vibration, and impact loads, extending its service life and reducing the risk of premature failure. Proper reinforcement techniques not only enhance the structural integrity of the gearbox housing but also contribute to the overall reliability and efficiency of the gearbox system.

When addressing gearbox oil foaming issues, it is important to first identify the root cause of the problem. Common causes of gearbox oil foaming include high operating temperatures, improper oil levels, air leaks in the system, and excessive agitation of the oil. To resolve this issue, one can consider using anti-foaming additives, ensuring proper oil levels, fixing any air leaks, and reducing the amount of agitation in the system. Regular maintenance and monitoring of the gearbox can also help prevent foaming issues from occurring in the future. By taking these steps, one can effectively address gearbox oil foaming problems and ensure smooth operation of the equipment.

Determining the appropriate gearbox lubrication interval involves considering factors such as the type of gearbox, operating conditions, temperature, load, and speed. It is important to consult the manufacturer's guidelines and recommendations for the specific gearbox model being used. Regular monitoring of the gearbox's performance, including noise levels, vibration, and temperature, can also help determine when lubrication is needed. Additionally, conducting oil analysis tests can provide valuable insights into the condition of the lubricant and help establish a suitable maintenance schedule. Proper lubrication is essential for ensuring optimal gearbox performance and longevity, so it is crucial to follow a proactive maintenance approach based on the unique requirements of the equipment in use.

One way to detect gearbox vibration issues is by conducting regular vibration analysis using specialized equipment such as accelerometers, tachometers, and vibration meters. By monitoring the frequency, amplitude, and overall vibration levels of the gearbox components, technicians can identify any abnormal vibrations that may indicate potential issues such as misalignment, worn bearings, gear tooth damage, or lubrication problems. Additionally, performing visual inspections of the gearbox for signs of wear, corrosion, or leaks can also help in detecting vibration issues early on. It is important to establish baseline vibration levels for comparison and to follow manufacturer guidelines for maintenance and lubrication to prevent excessive vibration and prolong the life of the gearbox.

Indicators of gearbox gear mesh misalignment can include abnormal noise during operation, such as grinding, clicking, or whining sounds. Other signs may include vibration, increased wear on gear teeth, and overheating of the gearbox. In some cases, there may be a decrease in overall efficiency and performance of the gearbox. It is important to address gear mesh misalignment promptly to prevent further damage to the gearbox and ensure optimal functioning of the equipment. Regular maintenance and inspection can help identify and correct misalignment issues before they escalate.