The material composition of the gearbox housing plays a crucial role in determining its stress resistance. Materials with high tensile strength, such as steel or aluminum alloys, are often preferred for their ability to withstand the forces and pressures exerted on the housing. Additionally, factors like hardness, ductility, and fatigue resistance also contribute to the overall stress resistance of the gearbox housing.

The design of the gearbox housing is essential in ensuring that stress is distributed evenly throughout the structure. Features such as ribbing, gussets, and fillets help to reinforce weak points and prevent stress concentrations. By optimizing the design to evenly distribute stress, the gearbox housing can better withstand the forces it is subjected to during operation.

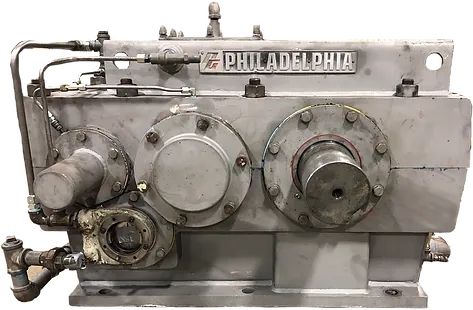

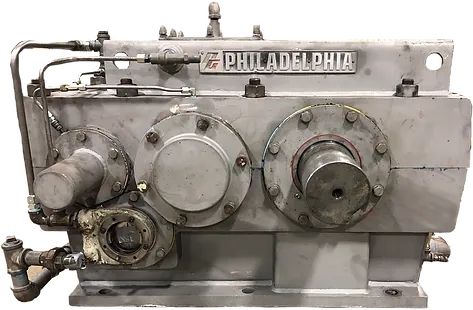

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

Houston officials and community members are touting the success of the barricades they say have driven away prostitutes and those actively seeking them.

Posted by on 2024-03-11

The 54-year-old Anderson, known for feature-length films such as "Rushmore," "The Royal Tenenbaums," "Fantastic Mr. Fox" and "Asteroid City," won in the Best Live Action Short Film category for "The Wonderful Story of Henry Sugar." He had previously been nominated for seven Academy Awards.

Posted by on 2024-03-11

Attorney General Ken Paxton has now targeted seven school districts over alleged electioneering in what he calls an effort to stop elections from being “illegally swayed by public officials improperly using state resources.” Those school districts are responding.

Posted by on 2024-03-11

Shead was the only unanimous pick on the first team announced Sunday.

Posted by on 2024-03-11

External factors like temperature and pressure can significantly impact the stress levels within the gearbox housing. High temperatures can cause thermal expansion and contraction, leading to additional stress on the housing. Similarly, fluctuations in pressure can result in varying levels of internal stress, potentially causing deformation or failure if not properly accounted for in the design.

Common failure points in gearbox housing due to stress often include cracks, fractures, and deformations in areas of high stress concentration. To mitigate these issues, engineers can implement measures such as adding reinforcements, improving material selection, or adjusting the design to reduce stress concentrations. Regular maintenance and inspections can also help identify potential failure points before they escalate.

The manufacturing process of the gearbox housing can have a significant impact on its stress resistance. Factors such as casting quality, heat treatment, and machining precision can all influence the structural integrity of the housing. By ensuring high-quality manufacturing processes are followed, the gearbox housing can be more resilient to stress and less prone to failure.

When conducting a stress analysis on gearbox housing, key parameters to consider include the material properties, loading conditions, boundary constraints, and geometric features of the housing. By accurately modeling these parameters in a simulation, engineers can predict how stress will be distributed throughout the housing and identify potential areas of concern that may require reinforcement or redesign.

Computer simulations are valuable tools for predicting and analyzing stress levels in gearbox housing before physical testing. By inputting the relevant parameters and running simulations, engineers can visualize stress distribution, identify potential failure points, and optimize the design for improved stress resistance. This allows for more efficient and cost-effective design iterations, ultimately leading to a more robust gearbox housing.

Gearbox breather vents play a crucial role in maintenance by allowing for the release of excess pressure and preventing the buildup of moisture and contaminants within the gearbox. These vents help to regulate the internal temperature of the gearbox, ensuring optimal performance and longevity of the components. By allowing for the escape of gases and preventing the ingress of debris, breather vents help to maintain the proper lubrication and functionality of the gearbox. Regular inspection and maintenance of these vents are essential to prevent issues such as overheating, corrosion, and premature wear of gearbox components. Proper care of gearbox breather vents can extend the lifespan of the gearbox and reduce the likelihood of costly repairs.

The key components of a gearbox lubrication system include a reservoir or oil pan to store the lubricant, a pump to circulate the oil throughout the gearbox, a filter to remove any contaminants from the oil, and a series of channels or passages to distribute the oil to the various components of the gearbox. Additionally, there may be sensors to monitor the oil level and temperature, as well as valves to control the flow of oil. Proper lubrication is essential for reducing friction, dissipating heat, and preventing wear and tear on the gearbox components, ultimately extending the lifespan of the system. Regular maintenance and monitoring of the lubrication system are crucial to ensure optimal performance and efficiency.

In marine applications, specialized gearbox maintenance procedures are essential to ensure optimal performance and longevity of the equipment. These procedures typically involve regular inspections, lubrication checks, and alignment adjustments to prevent wear and tear caused by harsh marine environments. Specific tasks may include checking oil levels, monitoring for water contamination, inspecting seals and gaskets, and replacing worn components as needed. Additionally, marine gearbox maintenance may also involve monitoring vibration levels, conducting oil analysis, and following manufacturer recommendations for service intervals. By following these specialized procedures, marine operators can minimize downtime, reduce the risk of costly repairs, and prolong the lifespan of their gearboxes.

To assess gearbox wear and tear, one can start by inspecting the gears, bearings, shafts, and seals for any signs of damage such as pitting, scoring, or corrosion. It is also important to check for any abnormal noises, vibrations, or leaks coming from the gearbox. Additionally, measuring the backlash, runout, and gear tooth wear can provide valuable information about the condition of the gearbox. Performing oil analysis can help determine if there are any metal particles or contaminants present in the lubricant, indicating potential wear. Regular maintenance and monitoring of these factors can help prevent further damage and ensure the gearbox operates efficiently.

Gearbox temperature sensors play a crucial role in maintenance by monitoring the temperature of the gearbox to ensure optimal performance and prevent overheating. These sensors provide real-time data on the temperature of the gearbox, allowing maintenance technicians to identify any potential issues before they escalate. By detecting abnormal temperature fluctuations, these sensors help prevent damage to the gearbox components and extend the lifespan of the equipment. Additionally, gearbox temperature sensors can trigger alerts or shut down the system automatically if the temperature exceeds safe levels, preventing costly repairs and downtime. Regular monitoring and analysis of the data from these sensors are essential for proactive maintenance and ensuring the reliability of the gearbox.

One way to identify gearbox oil leaks is to look for visible signs of oil dripping or pooling underneath the vehicle. Other indicators may include a decrease in oil levels, a burning smell coming from the engine, or unusual noises while driving. Inspecting the gearbox for cracks, loose fittings, or damaged seals can also help pinpoint the source of the leak. Additionally, checking for oil residue on the transmission housing or surrounding components can provide clues as to where the leak is originating from. Regular maintenance and inspections can help prevent gearbox oil leaks and ensure optimal performance of the vehicle.