Gearbox shaft bending that requires straightening procedures can be caused by various factors such as excessive loads, misalignment, improper installation, or wear and tear over time. These issues can lead to the shaft becoming bent, affecting the overall performance and efficiency of the gearbox system.

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

Determining if a gearbox shaft is bent and in need of straightening can be done through visual inspection and measurements. Signs of a bent shaft may include unusual vibrations, noise, or irregular wear patterns on the gears. Using precision measuring tools such as dial indicators can help accurately assess the extent of the bending.

The Esperanza "Hope" Andrade, named after a former Texas Secretary of State, is the first boat at the Galveston Ferry to be named after a woman and the first in Texas to be named after a Latina, according to TxDOT.

Posted by on 2024-03-12

The 54-year-old Anderson, known for feature-length films such as "Rushmore," "The Royal Tenenbaums," "Fantastic Mr. Fox" and "Asteroid City," won in the Best Live Action Short Film category for "The Wonderful Story of Henry Sugar." He had previously been nominated for seven Academy Awards.

Posted by on 2024-03-11

Attorney General Ken Paxton has now targeted seven school districts over alleged electioneering in what he calls an effort to stop elections from being “illegally swayed by public officials improperly using state resources.” Those school districts are responding.

Posted by on 2024-03-11

Episode: 1131 John Hunter: idiosyncratic medical pioneer. Today, the history of medicine provides a strange hero.

Posted by on 2024-03-10

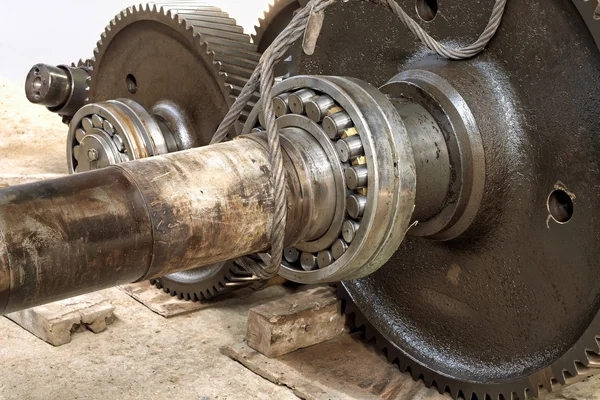

Tools and equipment commonly used for straightening a gearbox shaft include hydraulic presses, dial indicators, alignment bars, and heat sources. Hydraulic presses provide the necessary force to straighten the shaft, while dial indicators help in measuring the amount of deflection. Alignment bars assist in aligning the shaft properly during the straightening process.

The process of straightening a gearbox shaft typically involves securing the shaft in a hydraulic press, applying controlled pressure to the bent areas, and using dial indicators to monitor the progress. Heat may be applied to help soften the metal for easier straightening. The shaft is gradually straightened until it meets the required specifications.

Safety precautions are crucial when straightening a gearbox shaft to prevent accidents or injuries. Proper personal protective equipment such as gloves, goggles, and steel-toed boots should be worn. Ensuring the work area is clear of any obstructions and following proper procedures for using the hydraulic press are essential for a safe straightening process.

Improperly straightening a gearbox shaft can lead to further damage or even failure of the shaft. Over-straightening or applying excessive force can weaken the metal, causing it to deform or crack. This can result in catastrophic failure of the gearbox system, leading to costly repairs or replacements.

To prevent gearbox shaft bending in the future and avoid the need for straightening procedures, regular maintenance and inspections are key. Ensuring proper alignment, lubrication, and operating within the recommended load limits can help prolong the life of the gearbox shaft. Addressing any issues promptly and following manufacturer guidelines for installation and maintenance can help prevent bending and prolong the lifespan of the gearbox system.

In order to reduce gearbox friction, various measures can be implemented. One approach is to use high-quality lubricants that have low viscosity and high thermal stability. Additionally, optimizing the gear tooth profile and surface finish can help minimize frictional losses. Utilizing advanced materials such as carbon fiber or ceramic coatings can also reduce friction within the gearbox. Proper alignment and clearance settings between gears can further decrease friction. Regular maintenance and monitoring of the gearbox components can ensure smooth operation and minimize friction over time. Overall, a combination of lubrication, design optimization, material selection, and maintenance practices can effectively reduce gearbox friction.

The performance of a gearbox can indeed be influenced by external factors such as temperature. Fluctuations in temperature can impact the viscosity of the lubricating oil within the gearbox, affecting its ability to properly lubricate the gears and bearings. Extreme temperatures can also cause thermal expansion or contraction of gearbox components, leading to misalignment or increased friction. Additionally, temperature variations can alter the material properties of gearbox components, potentially leading to premature wear or failure. Therefore, it is crucial for gearbox manufacturers to consider the effects of temperature on performance and design their products accordingly to ensure optimal operation in diverse environmental conditions.

Preventing gearbox corrosion in humid environments can be achieved by implementing various protective measures. One effective method is to apply a corrosion-resistant coating on the gearbox components, such as zinc plating or powder coating. Additionally, using desiccants or dehumidifiers in the surrounding area can help reduce moisture levels and prevent corrosion. Regularly inspecting the gearbox for any signs of corrosion and promptly addressing any issues can also help prevent further damage. Proper ventilation and ensuring proper drainage around the gearbox can also help mitigate the effects of humidity. Overall, a combination of protective coatings, moisture control, regular maintenance, and proper ventilation can help prevent gearbox corrosion in humid environments.

The maintenance schedule for gearbox seals should include regular inspections, typically every 6 months or as recommended by the manufacturer. During these inspections, it is important to check for any signs of wear, damage, or leaks in the seals. This can involve checking the seal material for cracks, tears, or deterioration, as well as ensuring proper alignment and tightness of the seals. Additionally, lubrication of the seals may be necessary to prevent friction and prolong their lifespan. Any issues found during inspections should be addressed promptly to prevent further damage to the gearbox and ensure optimal performance. Following a consistent maintenance schedule for gearbox seals can help prevent costly repairs and downtime in the long run.