The purpose of adjusting gearbox bearing preload is to ensure that the bearings are properly loaded to prevent excessive play or tightness in the gearbox. By adjusting the preload, the bearings are positioned correctly to maintain optimal performance and longevity of the gearbox.

The amount of preload in the gearbox bearings directly affects the performance by influencing the smoothness of operation, noise levels, and overall efficiency. Too little preload can result in excessive vibration and noise, while too much preload can lead to increased friction and premature wear of the bearings.

It's allergy season in Houston, and many are feeling its impact. But allergist Dr. Dat Tran said the pollen count is low compared to 2023.

Posted by on 2024-03-12

A temporary hold on the law was set to expire Wednesday, but the high court extended the pause.

Posted by on 2024-03-12

The Esperanza "Hope" Andrade, named after a former Texas Secretary of State, is the first boat at the Galveston Ferry to be named after a woman and the first in Texas to be named after a Latina, according to TxDOT.

Posted by on 2024-03-12

Other schools in Texas, including University of Houston, will remain test-optional.

Posted by on 2024-03-12

Common techniques used to adjust gearbox bearing preload include adjusting shims, using specialized tools such as bearing preload gauges, and following manufacturer guidelines for specific gearbox models. Proper adjustment is crucial to ensure the bearings are loaded correctly and the gearbox operates smoothly.

Determining the optimal preload for a specific gearbox application involves considering factors such as the load, speed, and operating conditions of the gearbox. It may require testing different preload levels and monitoring the performance to find the ideal setting that balances smooth operation and bearing longevity.

The potential risks of incorrect gearbox bearing preload adjustment include increased wear on the bearings, reduced efficiency, and potential damage to other components in the gearbox. Improper preload can lead to premature failure of the bearings and costly repairs or replacements.

Specialized tools such as bearing preload gauges, torque wrenches, and shims may be required for adjusting gearbox bearing preload accurately. These tools help ensure that the correct amount of preload is applied to the bearings to optimize performance and prevent damage.

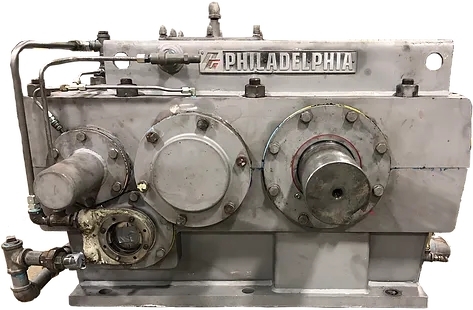

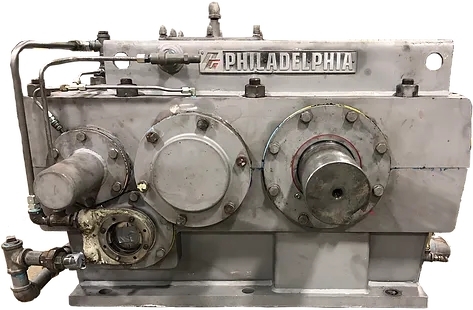

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

Gearbox bearing preload should be checked and adjusted regularly as part of routine maintenance to ensure optimal performance and longevity of the gearbox. Depending on the operating conditions and usage, it is recommended to check and adjust the preload at regular intervals to prevent issues and maintain the efficiency of the gearbox.

To prevent gearbox contamination during servicing, several measures can be taken. Firstly, it is important to ensure that the work area is clean and free of any debris that could potentially enter the gearbox. Using proper tools and equipment, such as clean funnels and filters, can also help prevent contamination. Additionally, technicians should wear appropriate protective gear, such as gloves and coveralls, to minimize the risk of introducing contaminants. Regularly inspecting and replacing seals and gaskets can help maintain the integrity of the gearbox and prevent leaks that could lead to contamination. Finally, following manufacturer guidelines for servicing and using high-quality lubricants can help ensure the gearbox remains clean and free of contaminants.

Preventing gearbox contamination can be achieved through various measures such as implementing effective sealing mechanisms, utilizing high-quality filtration systems, conducting regular maintenance checks, ensuring proper lubrication practices, and minimizing exposure to external contaminants. Additionally, employing proper storage techniques, utilizing clean tools and equipment during maintenance procedures, and adhering to manufacturer guidelines for gearbox operation can also help prevent contamination. By incorporating these preventive measures, the risk of gearbox contamination can be significantly reduced, leading to improved performance and longevity of the equipment.

In order to prevent gearbox corrosion in corrosive environments, several measures can be taken. One effective method is to regularly apply a corrosion-resistant coating to the gearbox components, such as zinc or nickel plating. Additionally, using materials that are specifically designed to withstand corrosive conditions, such as stainless steel or aluminum alloys, can help protect the gearbox from degradation. Implementing proper ventilation and drainage systems can also help reduce the buildup of moisture and corrosive agents around the gearbox. Regular maintenance and inspections to identify any signs of corrosion early on can prevent further damage and prolong the lifespan of the gearbox in corrosive environments.

Assessing gearbox lubricant degradation can be done through various methods such as monitoring viscosity changes, analyzing oxidation levels, checking for contamination, and evaluating additive depletion. Viscosity measurements can indicate if the lubricant is breaking down or becoming too thin, while oxidation levels can show the extent of chemical degradation. Contamination from water, dirt, or metal particles can also accelerate lubricant degradation. Additionally, monitoring the levels of additives such as anti-wear agents and detergents can provide insights into the overall health of the lubricant. Regular oil analysis and visual inspections can help in detecting signs of degradation early on to prevent potential damage to the gearbox.