The purpose of preloading gearbox bearings is to eliminate any internal clearance within the bearing system. By applying a controlled amount of force to the bearings, preloading ensures that there is no excessive play or movement between the components, which can lead to improved stiffness, reduced vibration, and increased overall system accuracy and performance.

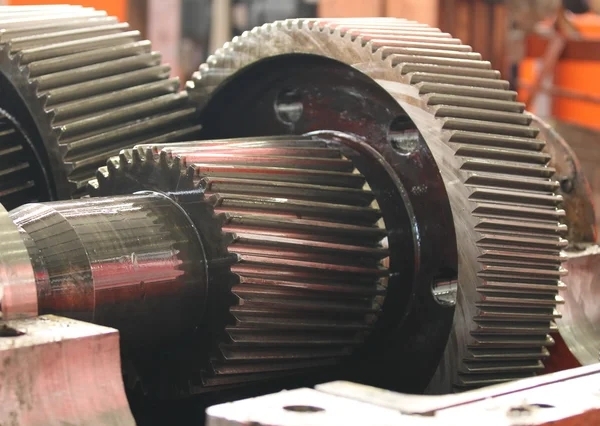

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

The amount of preload directly affects the performance of gearbox bearings. Too little preload can result in excessive internal clearance, leading to increased wear, noise, and potential failure of the bearings. On the other hand, excessive preload can cause increased friction, heat generation, and premature wear of the bearings. Therefore, it is crucial to apply the correct amount of preload to optimize the performance and longevity of the bearings.

Episode: 2851 The Lake Breeze Fan: Unplanned Obsolescence. Today, invention and obsolescence.

Posted by on 2024-03-12

The Livestock Show and Rodeo will continue through Sunday, March 17.

Posted by on 2024-03-11

The blooming cycle for Texas' state flower is 2-3 weeks ahead of schedule because of earlier-than-usual warm weather, according to Texas A&M horticulturalist Michael Arnold. Bluebonnets already can be seen in places such as the Houston Botanic Garden.

Posted by on 2024-03-11

After Gov. Greg Abbott said there should be consequences for the suspended cases via X, Whitmire suggested the state send money to Houston to help HPD.

Posted by on 2024-03-11

There are several methods used to preload gearbox bearings, including axial preloading, radial preloading, and angular contact preloading. Axial preloading involves applying a force parallel to the axis of rotation, while radial preloading applies force perpendicular to the axis. Angular contact preloading combines both axial and radial forces to achieve the desired preload. Each method has its advantages and is chosen based on the specific requirements of the gearbox system.

Overloading gearbox bearings can indeed lead to premature failure. Excessive preload can cause the bearings to overheat, wear out quickly, and ultimately fail. It is essential to carefully calculate and apply the correct amount of preload to ensure optimal performance and longevity of the bearings. Regular maintenance and monitoring of the preload are also necessary to prevent overloading and potential failures.

Determining the optimal preload for gearbox bearings involves considering factors such as the operating conditions, load requirements, speed, and desired performance of the system. It often requires a balance between minimizing internal clearance and avoiding excessive friction. Engineers typically use calculations, simulations, and testing to determine the ideal preload for a specific gearbox application.

Common signs of insufficient preload in gearbox bearings include excessive noise, vibration, and play in the system. If the bearings are not preloaded correctly, they may exhibit erratic behavior, reduced stiffness, and decreased overall performance. Regular inspection and monitoring of the bearings can help identify any issues with preload and prevent potential failures.

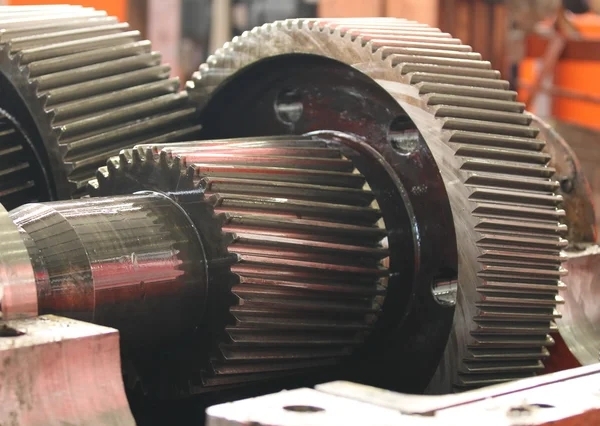

Specific tools and equipment are required for preloading gearbox bearings, such as bearing preload gauges, torque wrenches, shims, and spacers. These tools are used to accurately measure and apply the correct amount of preload to the bearings. Proper training and expertise are also essential when preloading gearbox bearings to ensure that the process is done correctly and effectively.

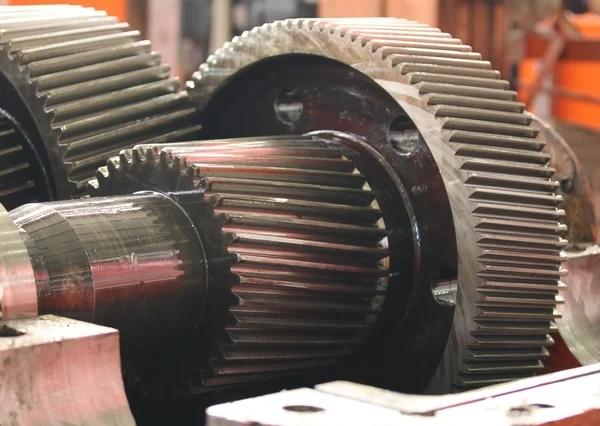

Indicators of gearbox bearing wear can include symptoms such as increased noise levels, vibration, and difficulty shifting gears. Other signs may include leaks of gearbox oil, unusual smells coming from the transmission, and a decrease in overall performance. Additionally, visible damage to the bearings themselves, such as cracks or wear marks, can also indicate that they are in need of replacement. It is important to address gearbox bearing wear promptly to prevent further damage to the transmission system and ensure the vehicle operates safely and efficiently. Regular maintenance and inspections can help identify and address bearing wear before it leads to more serious issues.

To prevent gearbox contamination during servicing, several measures can be taken. Firstly, it is important to ensure that the work area is clean and free of any debris that could potentially enter the gearbox. Using proper tools and equipment, such as clean funnels and filters, can also help prevent contamination. Additionally, technicians should wear appropriate protective gear, such as gloves and coveralls, to minimize the risk of introducing contaminants. Regularly inspecting and replacing seals and gaskets can help maintain the integrity of the gearbox and prevent leaks that could lead to contamination. Finally, following manufacturer guidelines for servicing and using high-quality lubricants can help ensure the gearbox remains clean and free of contaminants.

Preventing gearbox contamination can be achieved through various measures such as implementing effective sealing mechanisms, utilizing high-quality filtration systems, conducting regular maintenance checks, ensuring proper lubrication practices, and minimizing exposure to external contaminants. Additionally, employing proper storage techniques, utilizing clean tools and equipment during maintenance procedures, and adhering to manufacturer guidelines for gearbox operation can also help prevent contamination. By incorporating these preventive measures, the risk of gearbox contamination can be significantly reduced, leading to improved performance and longevity of the equipment.

In order to prevent gearbox corrosion in corrosive environments, several measures can be taken. One effective method is to regularly apply a corrosion-resistant coating to the gearbox components, such as zinc or nickel plating. Additionally, using materials that are specifically designed to withstand corrosive conditions, such as stainless steel or aluminum alloys, can help protect the gearbox from degradation. Implementing proper ventilation and drainage systems can also help reduce the buildup of moisture and corrosive agents around the gearbox. Regular maintenance and inspections to identify any signs of corrosion early on can prevent further damage and prolong the lifespan of the gearbox in corrosive environments.

Assessing gearbox lubricant degradation can be done through various methods such as monitoring viscosity changes, analyzing oxidation levels, checking for contamination, and evaluating additive depletion. Viscosity measurements can indicate if the lubricant is breaking down or becoming too thin, while oxidation levels can show the extent of chemical degradation. Contamination from water, dirt, or metal particles can also accelerate lubricant degradation. Additionally, monitoring the levels of additives such as anti-wear agents and detergents can provide insights into the overall health of the lubricant. Regular oil analysis and visual inspections can help in detecting signs of degradation early on to prevent potential damage to the gearbox.

Maintenance tasks for planetary gearboxes include checking for proper lubrication, inspecting gear teeth for wear, monitoring for any abnormal noises or vibrations during operation, and ensuring all bolts and fasteners are tightened to the correct torque specifications. Additionally, it is important to regularly clean the gearbox housing to prevent debris buildup and to inspect seals for any signs of leakage. Performing these routine maintenance tasks can help prolong the lifespan of the gearbox and prevent costly repairs down the line.