When joining gearbox housing components, it is recommended to follow specific welding procedures to ensure a strong and durable bond. These procedures may include preheating the components to a certain temperature, selecting the appropriate welding technique based on the materials being used, and using the correct filler material to match the base metals.

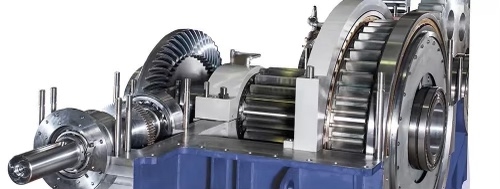

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

To ensure weld quality when welding gearbox housing, it is essential to carefully monitor the welding parameters such as heat input, travel speed, and electrode selection. Additionally, conducting non-destructive testing such as ultrasonic testing or radiographic testing can help detect any defects or discontinuities in the welds, ensuring the integrity of the gearbox housing.

The university is partnering with the Ibn Sina Foundation and the OakBend Medical Center in Richmond.

Posted by on 2024-03-12

It's allergy season in Houston, and many are feeling its impact. But allergist Dr. Dat Tran said the pollen count is low compared to 2023.

Posted by on 2024-03-12

A temporary hold on the law was set to expire Wednesday, but the high court extended the pause.

Posted by on 2024-03-12

The Esperanza "Hope" Andrade, named after a former Texas Secretary of State, is the first boat at the Galveston Ferry to be named after a woman and the first in Texas to be named after a Latina, according to TxDOT.

Posted by on 2024-03-12

The most commonly used welding technique for gearbox housing welding is gas metal arc welding (GMAW) or MIG welding. This technique allows for high deposition rates and good control over the welding process, making it suitable for joining gearbox housing components made of materials like aluminum or steel.

When welding gearbox housing, it is crucial to follow specific welding standards or codes to ensure the quality and integrity of the welds. Standards such as AWS D1.1 for structural welding or ISO 3834 for quality requirements for fusion welding of metallic materials provide guidelines for welding procedures, qualifications, and inspections.

Common defects to watch out for when welding gearbox housing include porosity, lack of fusion, cracks, and distortion. These defects can compromise the structural integrity of the gearbox housing and lead to premature failure. Regular inspection and quality control measures can help prevent these defects from occurring.

To minimize the heat-affected zone during gearbox housing welding, it is important to control the heat input and welding parameters. Using techniques such as pulse welding or adjusting the welding speed can help reduce the amount of heat transferred to the surrounding material, minimizing distortion and preserving the mechanical properties of the gearbox housing.

When welding different types of materials in gearbox housing construction, special considerations need to be taken into account. For example, when welding dissimilar metals such as aluminum to steel, it is important to use the appropriate filler material and welding technique to prevent galvanic corrosion. Additionally, preheating and post-weld heat treatment may be necessary for certain materials to ensure proper weld strength and integrity.

Determining the appropriate gearbox lubrication interval involves considering factors such as the type of gearbox, operating conditions, temperature, load, and speed. It is important to consult the manufacturer's guidelines and recommendations for the specific gearbox model being used. Regular monitoring of the gearbox's performance, including noise levels, vibration, and temperature, can also help determine when lubrication is needed. Additionally, conducting oil analysis tests can provide valuable insights into the condition of the lubricant and help establish a suitable maintenance schedule. Proper lubrication is essential for ensuring optimal gearbox performance and longevity, so it is crucial to follow a proactive maintenance approach based on the unique requirements of the equipment in use.

One way to detect gearbox vibration issues is by conducting regular vibration analysis using specialized equipment such as accelerometers, tachometers, and vibration meters. By monitoring the frequency, amplitude, and overall vibration levels of the gearbox components, technicians can identify any abnormal vibrations that may indicate potential issues such as misalignment, worn bearings, gear tooth damage, or lubrication problems. Additionally, performing visual inspections of the gearbox for signs of wear, corrosion, or leaks can also help in detecting vibration issues early on. It is important to establish baseline vibration levels for comparison and to follow manufacturer guidelines for maintenance and lubrication to prevent excessive vibration and prolong the life of the gearbox.

Indicators of gearbox gear mesh misalignment can include abnormal noise during operation, such as grinding, clicking, or whining sounds. Other signs may include vibration, increased wear on gear teeth, and overheating of the gearbox. In some cases, there may be a decrease in overall efficiency and performance of the gearbox. It is important to address gear mesh misalignment promptly to prevent further damage to the gearbox and ensure optimal functioning of the equipment. Regular maintenance and inspection can help identify and correct misalignment issues before they escalate.

The efficiency of a gearbox can indeed be influenced by the design of the gearbox housing. Factors such as the material used, the shape and size of the housing, the presence of cooling mechanisms, and the overall construction can all impact the performance of the gearbox. A well-designed gearbox housing can help to reduce friction, improve heat dissipation, enhance lubrication distribution, and minimize vibration, all of which can contribute to higher efficiency and smoother operation of the gearbox. Additionally, features such as proper sealing and alignment within the housing can also play a crucial role in maintaining optimal efficiency levels. Therefore, gearbox manufacturers often pay close attention to the housing design to ensure that it complements the internal components and contributes to overall performance.

To prevent gearbox contamination from external debris, several measures can be taken. One effective method is to install high-quality seals and gaskets to create a barrier between the gearbox and the surrounding environment. Regularly inspecting and maintaining these seals can help ensure they are functioning properly. Additionally, implementing proper ventilation systems can help prevent the buildup of dust and dirt around the gearbox. Keeping the surrounding area clean and free of debris can also help reduce the risk of contamination. Using filters and screens on any openings or vents can further prevent debris from entering the gearbox. Overall, a combination of these measures can help protect the gearbox from external contamination and ensure optimal performance.

When addressing gearbox gear tooth pitting, it is important to first identify the root cause of the issue, which can include factors such as improper lubrication, misalignment, overloading, or material defects. Once the cause is determined, the gears may need to be repaired or replaced to prevent further damage and ensure optimal performance. Common methods for addressing gear tooth pitting include grinding, shot peening, or applying surface treatments such as nitriding or carburizing to improve the hardness and wear resistance of the gears. Regular maintenance and monitoring of the gearbox can also help prevent future instances of gear tooth pitting.