The recommended micron ratings for gearbox lubrication system filters typically range from 5 to 20 microns. These filters are designed to capture particles of various sizes, ensuring that the lubricant remains clean and free of contaminants that could potentially damage the gearbox components. By using filters with the appropriate micron rating, the system can effectively remove particles that may cause wear and tear, ultimately prolonging the lifespan of the gearbox.

The viscosity of the lubricant directly impacts the filtration requirements for gearbox systems. Higher viscosity lubricants tend to require filters with larger surface areas and higher dirt-holding capacities to effectively remove contaminants. This is because thicker lubricants may contain more suspended particles that need to be filtered out to maintain optimal performance and prevent damage to the gearbox components. Therefore, selecting the right filter based on the viscosity of the lubricant is crucial for ensuring efficient filtration.

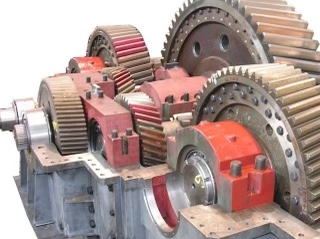

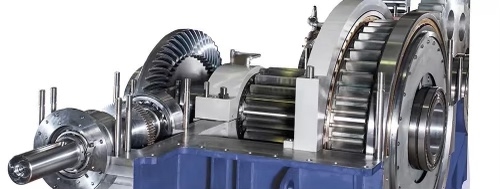

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

The cinema showed films for 64 continuous years, making it one of the longest-running theatres in the country.

Posted by on 2024-03-13

On Wednesday's show: We discuss the latest developments in politics, including whether runoffs ever have dramatically different results. Then we consider if we are ready for the next major public health emergency.

Posted by on 2024-03-13

Episode: 2998 Test Tube Evolution. Today, evolution in a test tube.

Posted by on 2024-03-13

Dr. Talat Jehan Khan, a pediatrician for Texas Children's Hospital, was stabbed to death Oct. 28 in an outdoor common area at Alys Luxury Living in Conroe. The man accused of killing her is jailed and faces a murder charge.

Posted by on 2024-03-12

The university is partnering with the Ibn Sina Foundation and the OakBend Medical Center in Richmond.

Posted by on 2024-03-12

Bypass filtration plays a critical role in maintaining gearbox lubrication system efficiency by providing an additional layer of filtration for the lubricant. This process involves diverting a portion of the oil flow through a separate filter with a finer micron rating, allowing for the removal of smaller particles that may have bypassed the primary filter. By incorporating bypass filtration, gearbox systems can achieve higher levels of cleanliness and extend the life of the lubricant, ultimately improving the overall performance of the system.

Gearbox lubrication system filters should be replaced at regular intervals to ensure optimal performance. The frequency of filter replacement depends on various factors such as the operating conditions, the type of contaminants present, and the manufacturer's recommendations. Typically, filters are replaced during routine maintenance schedules to prevent clogging and maintain efficient filtration. By replacing filters as recommended, gearbox systems can continue to operate smoothly and prevent potential damage caused by contaminated lubricant.

Using filters with inadequate dirt-holding capacity in gearbox lubrication systems can lead to several consequences. These filters may become clogged more quickly, reducing their effectiveness in removing contaminants from the lubricant. As a result, particles may circulate within the system, causing increased wear on gearbox components and potentially leading to system failure. It is essential to use filters with sufficient dirt-holding capacity to ensure proper filtration and prevent damage to the gearbox.

The type of contaminants present in gearbox systems can significantly impact the selection of filtration media. Different contaminants, such as metal particles, dirt, or water, require specific filter media to effectively capture and remove them from the lubricant. For example, metal particles may require a filter with magnetic properties, while water contamination may necessitate the use of coalescing filters. By understanding the types of contaminants present, gearbox systems can select the appropriate filtration media to maintain cleanliness and protect system components.

The benefits of using high-efficiency filters in gearbox lubrication systems compared to standard filters are significant. High-efficiency filters are designed to capture smaller particles and provide superior filtration performance, resulting in cleaner lubricant and reduced wear on gearbox components. These filters can help extend the life of the lubricant, improve system reliability, and minimize maintenance costs. By investing in high-efficiency filters, gearbox systems can operate more efficiently and effectively, ultimately enhancing overall performance and longevity.

The performance of a gearbox can indeed be affected by changes in altitude. Altitude variations can impact the air density, which in turn affects the cooling efficiency of the gearbox. Additionally, altitude changes can alter the pressure levels, potentially leading to issues with lubrication and overall gearbox functionality. It is important for gearbox manufacturers to consider these factors and design their products to withstand different altitude conditions to ensure optimal performance in various environments. Proper maintenance and adjustments may be necessary to account for altitude changes and prevent any negative effects on gearbox performance.

The efficiency of a gearbox can indeed be affected by changes in altitude. As altitude increases, the air becomes less dense, which can impact the performance of the gearbox. This is particularly true for gearboxes in vehicles or machinery that rely on air for cooling, as the reduced air density at higher altitudes can lead to decreased cooling efficiency. Additionally, changes in altitude can also affect the lubrication of the gearbox, as lower air pressure can result in reduced oil flow and lubrication effectiveness. Therefore, it is important for manufacturers to consider altitude variations when designing gearboxes to ensure optimal performance across different environments.

Seals play a crucial role in gearbox protection by preventing the leakage of lubricants and contaminants, such as dirt, water, and debris, into the gearbox system. These seals create a barrier between the internal components of the gearbox and the external environment, ensuring optimal performance and longevity of the gearbox. By maintaining a tight seal, seals help to reduce friction, wear, and corrosion within the gearbox, ultimately extending the lifespan of the equipment. Additionally, seals help to maintain proper lubrication levels within the gearbox, ensuring smooth operation and preventing overheating. Overall, seals are essential components in gearbox protection, safeguarding the system against potential damage and ensuring efficient operation.

Specialized gearbox maintenance procedures for oil and gas applications typically involve regular inspections, lubrication checks, and vibration analysis to ensure optimal performance and prevent costly downtime. These procedures may include monitoring oil levels, changing filters, inspecting seals, and checking for any signs of wear or damage. Additionally, specialized tools and equipment may be used to accurately measure gear tooth wear, alignment, and backlash. It is important to follow manufacturer recommendations and industry standards to maintain the efficiency and reliability of gearboxes in oil and gas applications. Regular maintenance can help extend the lifespan of equipment and minimize the risk of unexpected failures in critical operations.