Pitting can significantly impact the wear pattern on gear teeth by creating localized areas of damage that can lead to accelerated wear. The presence of pits on the gear tooth surface can cause stress concentrations, which can result in increased friction and wear. As the pits grow in size and depth, they can alter the contact pattern between gear teeth, leading to uneven wear and potentially causing premature failure of the gear system.

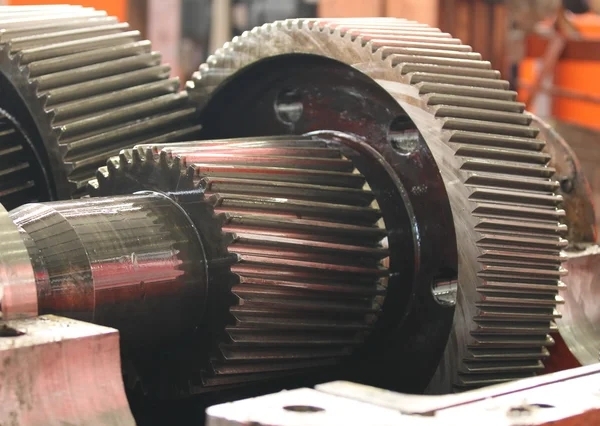

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

Lubrication plays a crucial role in determining the wear pattern on gear teeth by reducing friction and minimizing wear. Proper lubrication helps to create a protective film between the gear teeth, which reduces direct metal-to-metal contact and prevents surface damage. Inadequate lubrication can lead to increased friction, heat generation, and wear, resulting in a different wear pattern on the gear teeth.

Roxanna Asgarian discusses her book on the tragedy of the Hart family and their adopted children.

Posted by on 2024-03-13

In Texas and across the country, young people and their families have become increasingly skeptical of the benefits of college. Negative public perception of higher education costs has mostly centered around four-year, private institutions. Experts say community colleges often get lumped into that conversation, even though they usually have lower tuition rates.

Posted by on 2024-03-13

Chief Daniel Rodriguez was taking pre-scheduled vacation time in Phoenix during the Robb Elementary School shooting on May 24, 2022.

Posted by on 2024-03-13

The event will host 20 mile, 40 mile and 60 mile races around the metropolitan, but a map hasn't yet been released. Beginning and ending at Avenida de las Americas at Discovery Green, check-in and registration for the event begins at 6:30 a.m. The routes are secured until 1 p.m., and riders can hop on the sag wagon to continue the ride without support after that, according to the event's webpage.

Posted by on 2024-03-13

The material composition of the gear can have a significant impact on the wear pattern of the teeth. Different materials have varying hardness, strength, and wear resistance properties, which can affect how the gear teeth wear over time. Harder materials may exhibit less wear but can be more prone to brittle failure, while softer materials may wear more quickly but offer better resistance to impact loading. The material composition of the gear must be carefully selected to ensure optimal performance and longevity.

The operating temperature of the gear system can influence the wear pattern on the teeth by affecting the lubrication properties and material behavior. High temperatures can degrade the lubricant, leading to increased friction and wear between gear teeth. Additionally, elevated temperatures can alter the material properties of the gear, such as hardness and strength, which can impact the wear pattern. Proper cooling and temperature control are essential to maintaining the desired wear characteristics of the gear teeth.

Abrasive wear on gear teeth can be caused by various factors, including the presence of contaminants, improper lubrication, and high operating loads. Abrasive particles can become embedded in the gear tooth surface, leading to accelerated wear and a distinct wear pattern. Contaminants such as dirt, dust, and metal particles can act as abrasives, causing abrasive wear on the gear teeth. Regular cleaning, proper lubrication, and maintenance practices can help prevent abrasive wear and preserve the integrity of the gear teeth.

The tooth profile design of gears can significantly influence the wear pattern on the teeth. The shape and geometry of the gear teeth determine how the load is distributed across the contact area, affecting the wear characteristics. Different tooth profiles, such as involute, cycloidal, or trochoidal, can result in varying wear patterns and performance outcomes. The tooth profile design must be carefully considered to ensure optimal load distribution, minimal wear, and efficient power transmission.

Various methods can be used to analyze and monitor the wear pattern on gear teeth, including visual inspection, surface profilometry, and wear debris analysis. Visual inspection involves examining the gear teeth for signs of wear, such as pitting, scoring, or surface damage. Surface profilometry can be used to measure the surface roughness and wear depth of the gear teeth, providing quantitative data on the wear pattern. Wear debris analysis involves collecting and analyzing particles generated during gear operation to identify the wear mechanisms and patterns. By utilizing these methods, engineers can assess the condition of the gear teeth and implement appropriate maintenance strategies to prolong the gear system's lifespan.

Various types of gear tooth damage can indicate gearbox problems, such as pitting, spalling, scoring, and wear. Pitting occurs when small craters or pits form on the gear teeth due to excessive loads or inadequate lubrication. Spalling is characterized by the flaking or chipping of the gear tooth surface, often caused by fatigue or material defects. Scoring refers to the presence of scratches or grooves on the gear teeth, typically caused by abrasive contaminants in the lubricant. Wear, on the other hand, occurs when the gear teeth gradually lose material over time due to friction and load. Identifying these types of gear tooth damage is crucial in diagnosing gearbox issues and preventing further damage to the system.

In food-grade applications, there are specific gearbox maintenance requirements that must be adhered to in order to ensure compliance with industry regulations and standards. These requirements typically include regular inspections, lubrication checks, and cleaning procedures to prevent contamination and ensure the gearbox operates efficiently. It is important to use food-grade lubricants and materials that are safe for use in food processing environments. Additionally, proper documentation and record-keeping of maintenance activities are essential for traceability and audit purposes. Failure to follow these maintenance requirements can result in product contamination, equipment failure, and potential regulatory violations. Therefore, it is crucial for operators in food-grade applications to prioritize gearbox maintenance as part of their overall food safety program.

When troubleshooting gearbox lubrication pump problems, it is important to first check for any leaks, blockages, or malfunctions in the pump system. Inspect the pump for any signs of wear and tear, such as damaged seals or bearings. Ensure that the pump is properly lubricated and that the oil levels are within the recommended range. Test the pump's pressure and flow rate to determine if it is functioning correctly. Additionally, check the pump's electrical connections and controls to ensure they are working properly. If the issue persists, it may be necessary to consult a professional technician for further diagnosis and repair.

When determining the appropriate gearbox lubricant type, it is important to consider factors such as viscosity, additives, and base oil type. Viscosity is crucial as it affects the lubricant's ability to flow and provide adequate protection to the gearbox components. Additives, such as anti-wear agents and corrosion inhibitors, can enhance the lubricant's performance and extend the gearbox's lifespan. The base oil type, whether mineral, synthetic, or semi-synthetic, also plays a significant role in determining the lubricant's compatibility with the gearbox materials and operating conditions. Conducting a thorough analysis of the gearbox specifications, manufacturer recommendations, and operating environment can help in selecting the most suitable lubricant type for optimal performance and longevity.