The advantages of using diamond-like carbon (DLC) coating on gearbox gear tooth surfaces are numerous. DLC coatings provide exceptional hardness, low friction, and high wear resistance, which can significantly extend the lifespan of gear teeth. The coating also reduces the risk of galling and adhesive wear, leading to smoother operation and improved efficiency of the gearbox. Additionally, DLC coatings can enhance the corrosion resistance of gear teeth, making them more durable in harsh operating conditions.

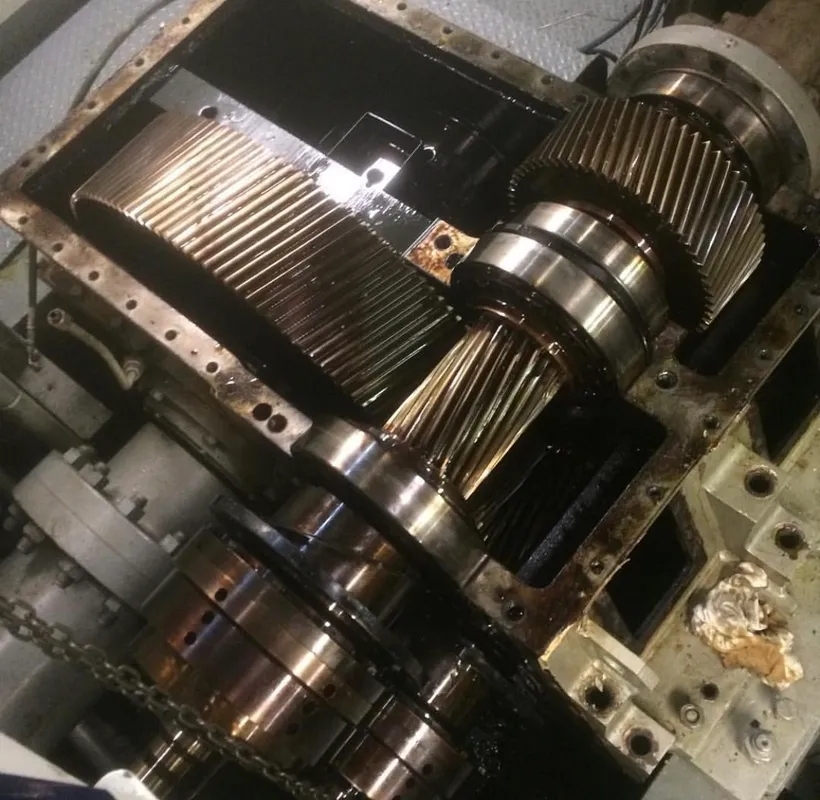

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

The process of physical vapor deposition (PVD) enhances the wear resistance of gearbox gear teeth by depositing a thin film of hard material onto the surface. This coating creates a protective barrier that reduces friction and prevents wear, extending the lifespan of the gear teeth. PVD coatings can improve the surface hardness of the gear teeth, making them more resistant to abrasion and fatigue. Overall, PVD coatings enhance the performance and durability of gearbox gear systems.

Episode: 2851 The Lake Breeze Fan: Unplanned Obsolescence. Today, invention and obsolescence.

Posted by on 2024-03-12

The Livestock Show and Rodeo will continue through Sunday, March 17.

Posted by on 2024-03-11

The blooming cycle for Texas' state flower is 2-3 weeks ahead of schedule because of earlier-than-usual warm weather, according to Texas A&M horticulturalist Michael Arnold. Bluebonnets already can be seen in places such as the Houston Botanic Garden.

Posted by on 2024-03-11

After Gov. Greg Abbott said there should be consequences for the suspended cases via X, Whitmire suggested the state send money to Houston to help HPD.

Posted by on 2024-03-11

“I was prepared to roll out some improvements and reforms, but was unsatisfied with the product that I received from Public Works yesterday,” said Mayor Whitmire during Tuesday’s public session meeting. “So I sent them back to the drawing board.”

Posted by on 2024-03-11

Thermal spray coatings can effectively protect gearbox gear teeth from corrosion and abrasion by creating a durable and wear-resistant barrier on the surface. These coatings are applied using a high-temperature process, which ensures strong adhesion to the substrate material. Thermal spray coatings can provide excellent protection against harsh operating conditions, extending the lifespan of gear teeth and improving the overall performance of the gearbox.

Ion implantation plays a crucial role in improving the hardness and durability of gearbox gear tooth surfaces. By bombarding the surface with high-energy ions, ion implantation can modify the material structure, increasing its hardness and wear resistance. This process can create a hardened layer on the surface of the gear teeth, making them more resistant to abrasion and fatigue. Ion implantation can significantly enhance the performance and longevity of gearbox gear systems.

Nitriding treatments contribute to the fatigue strength of gearbox gear teeth by diffusing nitrogen into the surface layer of the material. This process forms a hard nitride layer, which increases the surface hardness and wear resistance of the gear teeth. Nitriding treatments can improve the fatigue resistance of gear teeth, making them more durable and reliable in high-stress applications. Overall, nitriding treatments enhance the performance and longevity of gearbox gear systems.

Specific surface coating techniques can reduce friction and improve the efficiency of gearbox gear systems. For example, solid lubricant coatings can provide a low-friction surface that reduces wear and improves the overall performance of the gear teeth. Additionally, anti-friction coatings can enhance the lubrication properties of the gear teeth, reducing friction and improving the efficiency of the gearbox. These surface coating techniques play a crucial role in optimizing the performance of gearbox gear systems.

Different types of lubricants interact with coated gearbox gear tooth surfaces to enhance performance and longevity. For example, synthetic lubricants can provide superior lubrication properties, reducing friction and wear on the gear teeth. Additionally, additives in the lubricants can further enhance the protection of the coated surfaces, improving their durability and performance. Proper lubrication is essential for maintaining the efficiency and longevity of gearbox gear systems, especially when combined with advanced surface coatings.

The process of gearbox disassembly involves several steps that must be followed carefully to ensure the successful removal of components. First, the technician must drain the gearbox of any fluids and remove the external casing. Next, they will need to disconnect any electrical connections and remove any mounting bolts or brackets holding the gearbox in place. Once the gearbox is free from its mounting, the technician can begin to disassemble the internal components, such as gears, bearings, and shafts. Each component must be carefully removed and inspected for any signs of wear or damage. Finally, once all components have been removed, the technician can clean and inspect each part before reassembly. Following these steps will ensure a thorough gearbox disassembly process.

When addressing gearbox backlash issues, it is important to first identify the root cause of the problem. Common causes of gearbox backlash include worn gears, improper gear meshing, misalignment, or inadequate lubrication. To resolve these issues, one can adjust the gear meshing, replace worn gears, realign the gearbox components, and ensure proper lubrication. Additionally, implementing anti-backlash gears or using shims can help minimize backlash in the gearbox. Regular maintenance and inspections can also help prevent backlash issues from occurring in the future. By addressing these specific gearbox-related concerns, one can effectively reduce or eliminate backlash problems in the system.

To mitigate gearbox wear in harsh conditions, several measures can be taken. One option is to regularly inspect and maintain the gearbox to ensure all components are functioning properly. Using high-quality lubricants specifically designed for extreme conditions can help reduce friction and wear on the gears. Implementing proper cooling systems, such as heat exchangers or fans, can also help regulate the temperature of the gearbox and prevent overheating. Additionally, installing protective covers or shields can help shield the gearbox from debris and contaminants that could accelerate wear. Proper alignment and balancing of the gearbox components can also help distribute the load evenly and reduce wear on specific parts. Overall, a combination of regular maintenance, high-quality lubricants, cooling systems, protective covers, and proper alignment can help mitigate gearbox wear in harsh conditions.

One way to determine if a gearbox requires a rebuild is to look for signs of wear and tear such as grinding noises, difficulty shifting gears, leaking fluid, or a burning smell. Additionally, if there is excessive vibration or the gearbox is slipping, these could also indicate the need for a rebuild. It is important to regularly inspect the gearbox for any abnormalities and address any issues promptly to prevent further damage. A professional mechanic can conduct a thorough assessment to determine if a rebuild is necessary based on the specific symptoms and condition of the gearbox. Regular maintenance and servicing can help prolong the lifespan of a gearbox and prevent the need for a rebuild.

When determining the appropriate gearbox load capacity, engineers must consider various factors such as torque, speed, power, and operating conditions. The load capacity of a gearbox is typically determined by calculating the maximum torque that the gearbox can handle without causing damage or failure. This calculation involves analyzing the gear ratio, gear tooth strength, material properties, lubrication, and thermal management. Additionally, factors like shock loads, vibration, misalignment, and duty cycle must be taken into account to ensure the gearbox can withstand the intended application. Engineers may also use simulation software and testing procedures to validate the load capacity of the gearbox before implementation. By carefully evaluating these factors, engineers can select a gearbox with the appropriate load capacity to meet the requirements of the specific application.