Water contamination in gearbox lubricants can have a detrimental effect on their performance. Water can lead to rust formation, corrosion of metal surfaces, and a decrease in lubricant viscosity. This can result in increased friction, wear, and ultimately, premature failure of the gearbox components. Additionally, water contamination can promote the growth of microbes, further degrading the lubricant quality and reducing its effectiveness in protecting the gearbox.

Particulate contamination in gearbox lubricants can originate from various sources such as dust, dirt, metal wear particles, and debris from the environment. These particles can act as abrasives, causing increased wear on gearbox components and reducing the lubricant's ability to provide proper protection. Particulate contamination can also lead to increased friction, heat generation, and overall decreased efficiency of the gearbox system.

Roxanna Asgarian discusses her book on the tragedy of the Hart family and their adopted children.

Posted by on 2024-03-13

In Texas and across the country, young people and their families have become increasingly skeptical of the benefits of college. Negative public perception of higher education costs has mostly centered around four-year, private institutions. Experts say community colleges often get lumped into that conversation, even though they usually have lower tuition rates.

Posted by on 2024-03-13

Chief Daniel Rodriguez was taking pre-scheduled vacation time in Phoenix during the Robb Elementary School shooting on May 24, 2022.

Posted by on 2024-03-13

The event will host 20 mile, 40 mile and 60 mile races around the metropolitan, but a map hasn't yet been released. Beginning and ending at Avenida de las Americas at Discovery Green, check-in and registration for the event begins at 6:30 a.m. The routes are secured until 1 p.m., and riders can hop on the sag wagon to continue the ride without support after that, according to the event's webpage.

Posted by on 2024-03-13

Oxidation is a common issue that impacts the quality of gearbox lubricants. When lubricants are exposed to oxygen, high temperatures, and metal surfaces, they can undergo oxidation, leading to the formation of harmful by-products such as sludge and varnish. Oxidation can result in a decrease in lubricant performance, reduced film strength, and increased viscosity, ultimately affecting the gearbox's efficiency and longevity.

Additives play a crucial role in preventing gearbox lubricant contamination. Additives such as antioxidants, anti-wear agents, detergents, and dispersants help to enhance the lubricant's performance and protect it from degradation. These additives can inhibit oxidation, reduce wear, control deposits, and improve the overall cleanliness of the lubricant, thereby extending the life of the gearbox components and maintaining optimal performance.

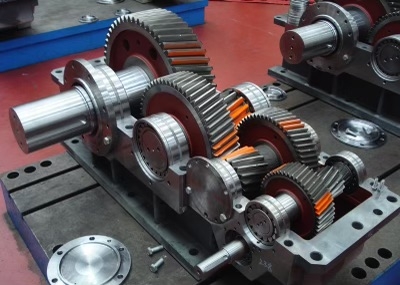

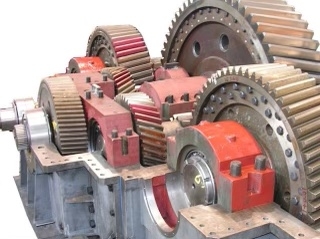

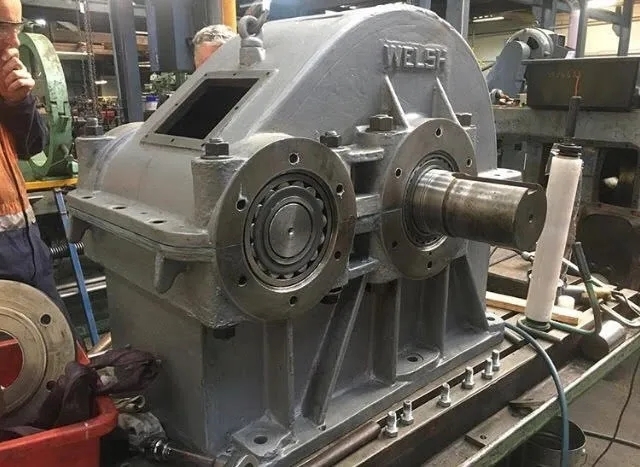

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

Microbial contamination in gearbox lubricants can be detected through various methods such as visual inspection, microbial testing kits, and laboratory analysis. Signs of microbial contamination include foul odors, unusual color changes, and the presence of slime or deposits in the lubricant. Microbial growth can lead to acidity, corrosion, and degradation of the lubricant, compromising its ability to protect the gearbox components effectively.

The consequences of using contaminated gearbox lubricants on equipment performance can be severe. Contamination can lead to increased friction, wear, and heat generation, resulting in accelerated component failure, reduced efficiency, and costly repairs. Using contaminated lubricants can also void warranties, compromise safety, and lead to unplanned downtime, impacting overall productivity and profitability.

Gearbox lubricant contamination can be prevented through proper maintenance practices such as regular oil analysis, filtration, and seal inspections. Implementing a proactive maintenance schedule, using high-quality lubricants, and ensuring proper storage and handling procedures can help minimize the risk of contamination. Additionally, maintaining clean operating environments, monitoring equipment conditions, and following manufacturer recommendations for lubricant selection and change intervals are essential steps in preventing gearbox lubricant contamination and ensuring optimal performance of the system.

Indicators of gearbox bearing wear can include symptoms such as increased noise levels, vibration, and difficulty shifting gears. Other signs may include leaks of gearbox oil, unusual smells coming from the transmission, and a decrease in overall performance. Additionally, visible damage to the bearings themselves, such as cracks or wear marks, can also indicate that they are in need of replacement. It is important to address gearbox bearing wear promptly to prevent further damage to the transmission system and ensure the vehicle operates safely and efficiently. Regular maintenance and inspections can help identify and address bearing wear before it leads to more serious issues.

To prevent gearbox contamination during servicing, several measures can be taken. Firstly, it is important to ensure that the work area is clean and free of any debris that could potentially enter the gearbox. Using proper tools and equipment, such as clean funnels and filters, can also help prevent contamination. Additionally, technicians should wear appropriate protective gear, such as gloves and coveralls, to minimize the risk of introducing contaminants. Regularly inspecting and replacing seals and gaskets can help maintain the integrity of the gearbox and prevent leaks that could lead to contamination. Finally, following manufacturer guidelines for servicing and using high-quality lubricants can help ensure the gearbox remains clean and free of contaminants.

Preventing gearbox contamination can be achieved through various measures such as implementing effective sealing mechanisms, utilizing high-quality filtration systems, conducting regular maintenance checks, ensuring proper lubrication practices, and minimizing exposure to external contaminants. Additionally, employing proper storage techniques, utilizing clean tools and equipment during maintenance procedures, and adhering to manufacturer guidelines for gearbox operation can also help prevent contamination. By incorporating these preventive measures, the risk of gearbox contamination can be significantly reduced, leading to improved performance and longevity of the equipment.

In order to prevent gearbox corrosion in corrosive environments, several measures can be taken. One effective method is to regularly apply a corrosion-resistant coating to the gearbox components, such as zinc or nickel plating. Additionally, using materials that are specifically designed to withstand corrosive conditions, such as stainless steel or aluminum alloys, can help protect the gearbox from degradation. Implementing proper ventilation and drainage systems can also help reduce the buildup of moisture and corrosive agents around the gearbox. Regular maintenance and inspections to identify any signs of corrosion early on can prevent further damage and prolong the lifespan of the gearbox in corrosive environments.