Various types of thermal insulation materials commonly used in gearbox housing include fiberglass, foam, ceramic fiber, and aerogel. These materials are chosen for their ability to effectively reduce heat transfer and maintain optimal operating temperatures within the gearbox.

The thermal conductivity of the insulation material directly impacts the overall efficiency of the gearbox. Lower thermal conductivity means less heat transfer, leading to reduced energy loss and improved performance. Choosing insulation materials with low thermal conductivity is crucial for enhancing gearbox efficiency.

Roxanna Asgarian discusses her book on the tragedy of the Hart family and their adopted children.

Posted by on 2024-03-13

In Texas and across the country, young people and their families have become increasingly skeptical of the benefits of college. Negative public perception of higher education costs has mostly centered around four-year, private institutions. Experts say community colleges often get lumped into that conversation, even though they usually have lower tuition rates.

Posted by on 2024-03-13

Chief Daniel Rodriguez was taking pre-scheduled vacation time in Phoenix during the Robb Elementary School shooting on May 24, 2022.

Posted by on 2024-03-13

The event will host 20 mile, 40 mile and 60 mile races around the metropolitan, but a map hasn't yet been released. Beginning and ending at Avenida de las Americas at Discovery Green, check-in and registration for the event begins at 6:30 a.m. The routes are secured until 1 p.m., and riders can hop on the sag wagon to continue the ride without support after that, according to the event's webpage.

Posted by on 2024-03-13

Thermal insulation can be applied externally to the gearbox housing or integrated into the design, depending on the specific requirements of the gearbox and the surrounding environment. External insulation can be added as a protective layer, while integrated insulation is built into the housing structure for seamless thermal management.

There are specific regulations and standards that dictate the type of thermal insulation to be used in gearbox housing, ensuring compliance with safety and performance requirements. These standards may vary depending on the industry and application of the gearbox, emphasizing the importance of using approved insulation materials.

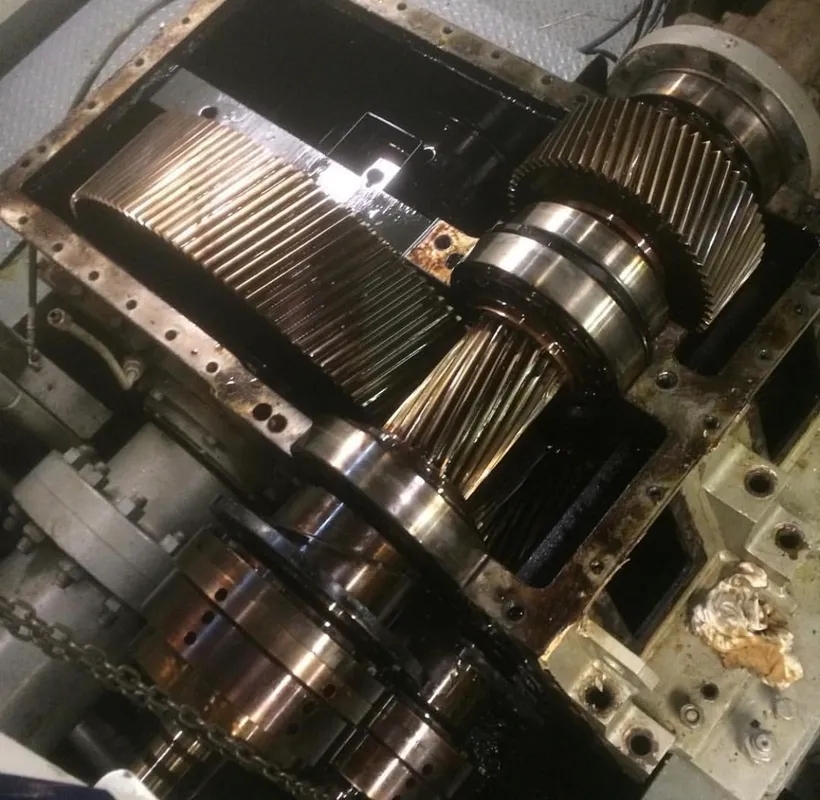

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

Inadequate thermal insulation in gearbox housing can lead to overheating, increased wear and tear on components, reduced efficiency, and potential breakdowns. Without proper insulation, the gearbox may experience temperature fluctuations that can negatively impact its performance and longevity.

The thickness of the insulation layer plays a crucial role in regulating temperatures within the gearbox housing. Thicker insulation provides better heat resistance and thermal protection, helping to maintain stable operating temperatures and prevent heat loss or buildup within the gearbox.

Innovative and advanced thermal insulation methods are being developed specifically for gearbox housing applications, such as phase change materials, nanotechnology-based insulators, and advanced composite materials. These cutting-edge solutions aim to further enhance thermal efficiency, reduce energy consumption, and improve overall performance of gearboxes in various industries.

Gearbox performance can indeed be affected by gearbox mounting issues. When the gearbox is not properly mounted, it can lead to misalignment, increased vibration, and premature wear on the gears and bearings. This can result in decreased efficiency, increased noise levels, and potential damage to other components within the transmission system. It is crucial to ensure that the gearbox is securely and accurately mounted to prevent any negative impacts on its overall performance and longevity. Regular maintenance and inspections of the gearbox mounting system are essential to avoid any potential issues that may arise from improper installation or mounting.

To prevent gearbox water ingress, several measures can be taken to ensure the integrity of the system. One effective method is to regularly inspect and maintain the gearbox seals to ensure they are in good condition and free from any cracks or damage. Additionally, applying a waterproof sealant or coating to vulnerable areas can help create an extra barrier against water penetration. Installing a breather vent with a filter can also help prevent moisture from entering the gearbox while still allowing for pressure equalization. Furthermore, ensuring proper drainage around the gearbox area can help prevent water from pooling and seeping into the system. Regularly monitoring the gearbox for any signs of water ingress, such as milky oil or corrosion, can also help detect any issues early on and prevent further damage.

Detecting gearbox oil oxidation can be done by monitoring the oil's color, viscosity, and odor. Oxidized gearbox oil may appear darker in color, have a thicker consistency, and emit a burnt or acrid smell. Additionally, testing the oil for acidity levels can also indicate oxidation. Other signs of gearbox oil oxidation include increased levels of sludge or varnish in the oil, decreased lubricating properties, and potential damage to the gearbox components. Regular oil analysis and maintenance can help prevent and detect gearbox oil oxidation before it causes significant damage to the system.

When troubleshooting gearbox clutch problems, it is important to first check for any signs of slipping, grinding, or difficulty shifting gears. Inspecting the clutch pedal for any unusual resistance or play can also provide valuable information. Additionally, examining the clutch fluid levels, clutch master cylinder, and clutch release bearing can help pinpoint the issue. Testing the clutch engagement and disengagement, as well as checking for any leaks or damage to the clutch components, can further aid in diagnosing the problem. It is recommended to consult a professional mechanic for a thorough inspection and proper diagnosis of gearbox clutch issues.

Gearbox lubrication failure can have severe consequences on the overall performance and longevity of a vehicle's transmission system. Without proper lubrication, the gears within the gearbox can experience increased friction, leading to excessive wear and tear. This can result in overheating, increased noise levels, and ultimately, mechanical failure. Additionally, inadequate lubrication can cause the gears to seize up or become misaligned, further compromising the functionality of the gearbox. In the long run, gearbox lubrication failure can lead to costly repairs or even the need for a full transmission replacement. Regular maintenance and monitoring of gearbox lubrication levels are essential to prevent these detrimental outcomes.

When troubleshooting gearbox cooling system problems, it is important to first check for any leaks in the system, such as from the transmission cooler or lines. Inspecting the radiator for any blockages or damage is also crucial. Additionally, checking the condition of the transmission fluid and ensuring it is at the correct level can help identify any issues. Testing the functionality of the thermostat, fan, and other cooling components can provide insight into potential malfunctions. It is recommended to consult the vehicle's manual for specific troubleshooting steps and to consider seeking professional assistance if needed. Regular maintenance and inspection of the gearbox cooling system can help prevent problems from occurring in the future.