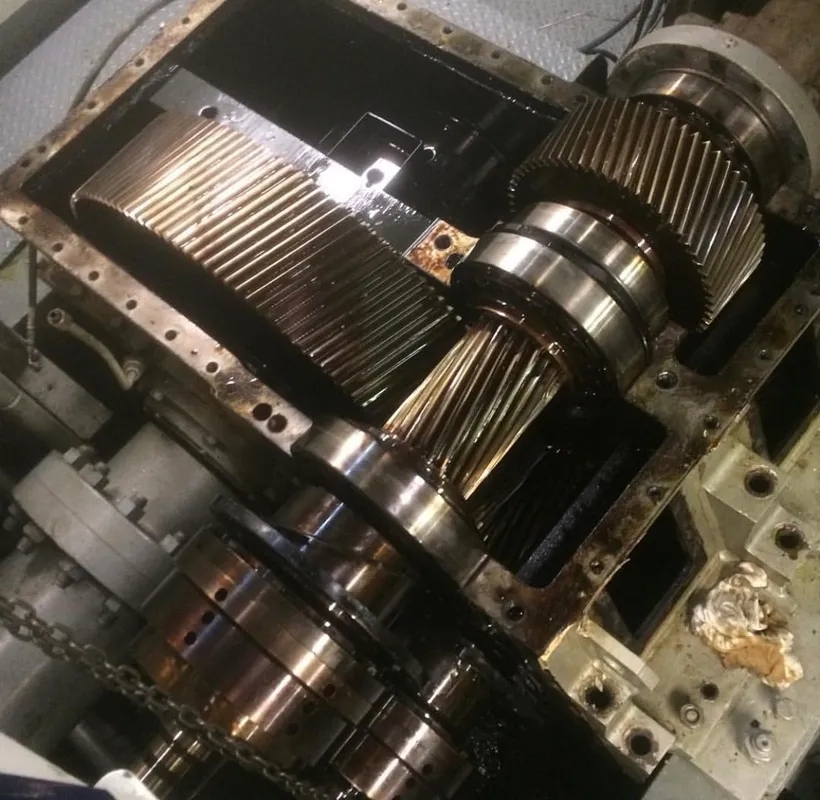

Common signs of wear and tear on a gearbox housing include visible cracks, dents, or corrosion on the surface, as well as oil leaks, unusual noises during operation, and difficulty shifting gears. These signs indicate that the gearbox housing may be compromised and in need of inspection or repair to prevent further damage to the internal components.

To prevent leaks in a gearbox housing, it is essential to regularly check and replace the seals and gaskets, ensure proper lubrication levels, and maintain the correct operating temperature. Additionally, avoiding overloading the gearbox, conducting routine inspections, and addressing any issues promptly can help prevent leaks and prolong the lifespan of the housing.

The cinema showed films for 64 continuous years, making it one of the longest-running theatres in the country.

Posted by on 2024-03-13

Roxanna Asgarian discusses her book on the tragedy of the Hart family and their adopted children.

Posted by on 2024-03-13

NFL free agency is underway, with teams able to negotiate with players now. They can start signing contracts Wednesday.

Posted by on 2024-03-11

Episode: 1132 In which balloons deliver the mail during the Siege of Paris. Today, the very first airmail service is used to break a siege.

Posted by on 2024-03-11

More than 16,000 additional babies were born in Texas in 2022 compared to 2021 after the state banned almost all abortions after six weeks of pregnancy, according to a University of Houston analysis of 2022 fertility data.

Posted by on 2024-03-11

Recommended maintenance procedures for gearbox housing include regular inspections for signs of wear and tear, checking and replacing seals and gaskets as needed, monitoring lubrication levels, and ensuring proper alignment of the gearbox components. It is also important to follow the manufacturer's guidelines for maintenance intervals and procedures to keep the gearbox housing in optimal condition.

Ignoring gearbox housing issues can lead to serious consequences such as complete gearbox failure, damage to internal components, increased risk of accidents or breakdowns, and costly repairs or replacements. It is crucial to address any signs of wear and tear on the gearbox housing promptly to prevent further damage and ensure the safe and efficient operation of the equipment.

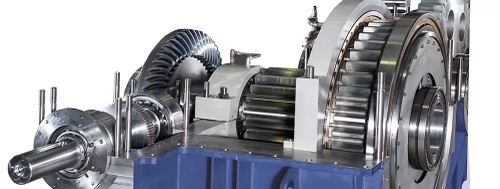

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

To determine if a gearbox housing needs to be replaced, one should look for severe damage such as extensive cracks, holes, or corrosion that cannot be repaired. Additionally, if the gearbox housing is causing persistent leaks, unusual noises, or difficulty shifting gears despite maintenance efforts, it may be time to consider replacing the housing to prevent further damage and ensure the proper functioning of the gearbox.

Different types of materials used in manufacturing gearbox housings include aluminum, cast iron, steel, and various alloys. Each material offers different strengths, durability, and heat resistance properties, depending on the specific requirements of the gearbox application. The choice of material for the gearbox housing is crucial in ensuring the longevity and performance of the equipment.

Specific tools or equipment required for inspecting gearbox housings may include a torque wrench, seal puller, gasket scraper, inspection mirror, and dial indicator. These tools are essential for checking the tightness of bolts, removing and replacing seals and gaskets, inspecting internal components, and measuring alignment and clearances within the gearbox housing. Proper use of these tools can help identify and address any issues with the gearbox housing effectively.

Maintenance tasks for planetary gearboxes include checking for proper lubrication, inspecting gear teeth for wear, monitoring for any abnormal noises or vibrations during operation, and ensuring all bolts and fasteners are tightened to the correct torque specifications. Additionally, it is important to regularly clean the gearbox housing to prevent debris buildup and to inspect seals for any signs of leakage. Performing these routine maintenance tasks can help prolong the lifespan of the gearbox and prevent costly repairs down the line.

When it comes to heavy-duty gearboxes, the best-suited lubrication systems are typically those that can handle high loads, extreme temperatures, and prolonged operation. Some of the most commonly used lubrication systems for heavy-duty gearboxes include circulating oil systems, splash lubrication systems, and forced-feed lubrication systems. Circulating oil systems are ideal for gearboxes that require continuous lubrication, as they pump oil through the gearbox to ensure all components are properly lubricated. Splash lubrication systems are often used in gearboxes with lower speeds and loads, as they rely on the gears splashing oil onto the components. Forced-feed lubrication systems are designed to deliver oil directly to the gears and bearings under high pressure, making them suitable for heavy-duty applications where precise lubrication is necessary. Overall, the best lubrication system for a heavy-duty gearbox will depend on factors such as load, speed, temperature, and operating conditions.

When troubleshooting gearbox noise issues, it is important to first identify the source of the noise. This can be done by checking for any loose or worn components such as bearings, gears, or shafts. Inspecting the gearbox for any signs of damage, such as cracks or leaks, can also help pinpoint the issue. Additionally, checking the gearbox oil level and quality can provide valuable information on the condition of the gearbox. Performing a visual inspection and listening for any abnormal sounds while the gearbox is in operation can further aid in diagnosing the problem. Once the source of the noise is identified, appropriate repairs or replacements can be made to resolve the issue and prevent further damage to the gearbox.

Indicators of gearbox seal failure can include leaks, drips, puddles of fluid underneath the vehicle, a decrease in fluid levels, unusual noises coming from the gearbox, difficulty shifting gears, and a burning smell. Other signs may include visible damage to the seal, such as cracks or tears, and a noticeable increase in vibration or shaking while driving. It is important to address gearbox seal failure promptly to prevent further damage to the transmission and ensure the safe operation of the vehicle. Regular maintenance and inspections can help identify potential issues with gearbox seals before they lead to more serious problems.

Gearbox misalignment can indeed lead to premature wear in machinery. When the gears in a gearbox are not properly aligned, it can cause increased friction, uneven distribution of forces, and excessive vibration. This can result in accelerated wear and tear on the gears, bearings, and other components of the gearbox. Over time, this can lead to decreased efficiency, increased maintenance costs, and ultimately, the need for premature replacement of parts. It is important to regularly check and correct any misalignment issues in gearboxes to prevent these negative consequences and ensure optimal performance and longevity of the machinery.