The most commonly used materials for reinforcing gearbox housings are steel, cast iron, and aluminum. Steel is known for its high strength and durability, making it a popular choice for heavy-duty applications. Cast iron is also favored for its excellent wear resistance and damping properties. Aluminum, on the other hand, is lightweight and corrosion-resistant, making it suitable for applications where weight is a concern.

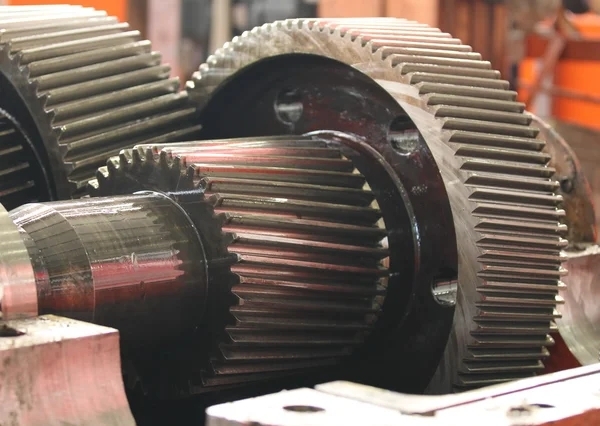

Expert Insights Into The Equipment Behind Industrial Gearbox Repair

The choice of material significantly impacts the strength and durability of a gearbox housing. Steel offers superior strength but may be heavier than other materials. Cast iron provides excellent wear resistance but can be brittle. Aluminum is lightweight but may not be as strong as steel or cast iron. Therefore, selecting the right material is crucial to ensure the gearbox housing can withstand the demands of the application.

On Tuesday's show: We discuss a number of environmental stories across the state. And we consider how to deal with seasonal allergies as we near the official start of spring.

Posted by on 2024-03-12

Episode: 2851 The Lake Breeze Fan: Unplanned Obsolescence. Today, invention and obsolescence.

Posted by on 2024-03-12

The Livestock Show and Rodeo will continue through Sunday, March 17.

Posted by on 2024-03-11

The blooming cycle for Texas' state flower is 2-3 weeks ahead of schedule because of earlier-than-usual warm weather, according to Texas A&M horticulturalist Michael Arnold. Bluebonnets already can be seen in places such as the Houston Botanic Garden.

Posted by on 2024-03-11

For high-performance or heavy-duty gearbox applications, materials like titanium, magnesium, or advanced composites may be recommended. Titanium is known for its high strength-to-weight ratio, making it ideal for applications where weight reduction is critical. Magnesium offers excellent strength and shock absorption properties. Advanced composites, such as carbon fiber reinforced polymers, provide a combination of strength, stiffness, and lightweight properties.

Using aluminum for gearbox housing reinforcement has its advantages and disadvantages. Aluminum is lightweight, corrosion-resistant, and easy to machine, making it a cost-effective option for many applications. However, aluminum may not offer the same level of strength as steel or cast iron, which could be a concern for heavy-duty applications. Additionally, aluminum may have lower thermal conductivity compared to other materials.

Composite materials offer a unique alternative to traditional metals for reinforcing gearbox housings. Composites, such as carbon fiber reinforced polymers, can provide high strength-to-weight ratios, excellent fatigue resistance, and corrosion resistance. While composites may be more expensive than traditional metals, they offer the advantage of being tailored to specific performance requirements, making them ideal for high-performance applications.

Innovative materials and technologies, such as metal matrix composites or additive manufacturing, are being used to enhance gearbox housing reinforcement. Metal matrix composites combine the strength of metals with the lightweight properties of composites, offering a unique combination of properties. Additive manufacturing allows for the production of complex geometries and customized designs, optimizing the performance of gearbox housings.

The cost of materials for gearbox housing reinforcement varies based on the material used. Steel and cast iron are typically more affordable options, making them suitable for cost-sensitive applications. Aluminum may fall in the mid-range in terms of cost, depending on the grade and specifications. Advanced materials like titanium or composites tend to be more expensive but offer superior performance characteristics, making them worth the investment for high-performance applications.

Specialized gearbox maintenance procedures for underground mining applications typically involve regular inspections, lubrication checks, and monitoring of vibration levels to ensure optimal performance and prevent breakdowns. These procedures may include the use of specialized tools and equipment, such as vibration analysis devices, to detect potential issues early on. Additionally, maintenance schedules may be more frequent in underground mining settings due to the harsh operating conditions and heavy loads placed on the gearboxes. Proper training for maintenance personnel is also crucial to ensure that all procedures are carried out correctly and efficiently. Overall, the goal of specialized gearbox maintenance in underground mining applications is to maximize equipment uptime and productivity while minimizing the risk of costly downtime.

Balancing can indeed enhance the performance of a gearbox by optimizing the distribution of weight and reducing vibrations that can lead to wear and tear. By carefully adjusting the mass distribution of the components within the gearbox, engineers can improve its efficiency, durability, and overall functionality. This process involves precision machining, dynamic balancing, and the use of specialized tools and techniques to ensure that all parts work together seamlessly. Additionally, balancing can help minimize noise levels, increase power transmission, and extend the lifespan of the gearbox. Overall, balancing plays a crucial role in enhancing gearbox performance and ensuring smooth operation in various applications.

When it comes to gearbox maintenance, there are several specialized tools that can be used to ensure optimal performance and longevity. Some of these tools include gear pullers, bearing pullers, torque wrenches, dial indicators, and gear shimming tools. Gear pullers are used to remove gears from shafts, while bearing pullers are used to remove bearings from gearboxes. Torque wrenches are essential for tightening bolts to the correct specifications, while dial indicators are used to measure gear backlash and runout. Gear shimming tools are used to adjust the spacing between gears for proper meshing. These specialized tools are designed to make gearbox maintenance easier and more efficient, ultimately helping to prevent costly repairs and downtime.

The efficiency of a gearbox can indeed be influenced by the material used for the gearbox housing. The choice of material can impact factors such as heat dissipation, weight, durability, and overall performance. For example, using lightweight materials like aluminum or magnesium can improve the efficiency by reducing the overall weight of the gearbox, leading to less energy loss during operation. Additionally, materials with good thermal conductivity can help dissipate heat more effectively, preventing overheating and improving overall efficiency. On the other hand, using materials with poor durability or high friction coefficients can negatively affect the gearbox's efficiency by increasing wear and energy loss. Therefore, selecting the appropriate gearbox housing material is crucial in optimizing the efficiency and performance of the gearbox.

Gearbox seals can indeed degrade over time due to various factors such as exposure to heat, friction, and contaminants. The material composition of the seals, including rubber or silicone, can break down over time, leading to cracks, leaks, and overall deterioration. Additionally, environmental conditions, such as temperature fluctuations and moisture, can also contribute to the degradation of gearbox seals. Regular maintenance and inspection of seals are crucial to ensure optimal performance and prevent potential issues with the gearbox system. It is important to replace worn-out seals promptly to avoid more significant damage to the gearbox components.

To prevent gearbox vibration, several measures can be taken. First, ensuring proper alignment of the gearbox components, such as shafts and gears, can help reduce vibration. Additionally, using high-quality lubricants and maintaining proper lubrication levels can minimize friction and vibration within the gearbox. Installing vibration dampening mounts or isolators can also help absorb any excess vibration. Regular maintenance and inspections of the gearbox, including checking for worn or damaged parts, can help prevent vibration issues from occurring. Lastly, balancing the rotating components of the gearbox can help reduce vibration and ensure smooth operation. By implementing these measures, gearbox vibration can be effectively prevented.